Method for digital detecting rotating equipment rotary speed and rotary direction with single sensor

A technology of rotating equipment and digital detection, which is applied to devices, instruments, and measuring devices using electric/magnetic methods, can solve the problems of increasing detection costs and sensor installation costs, and achieves the effect of simple structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

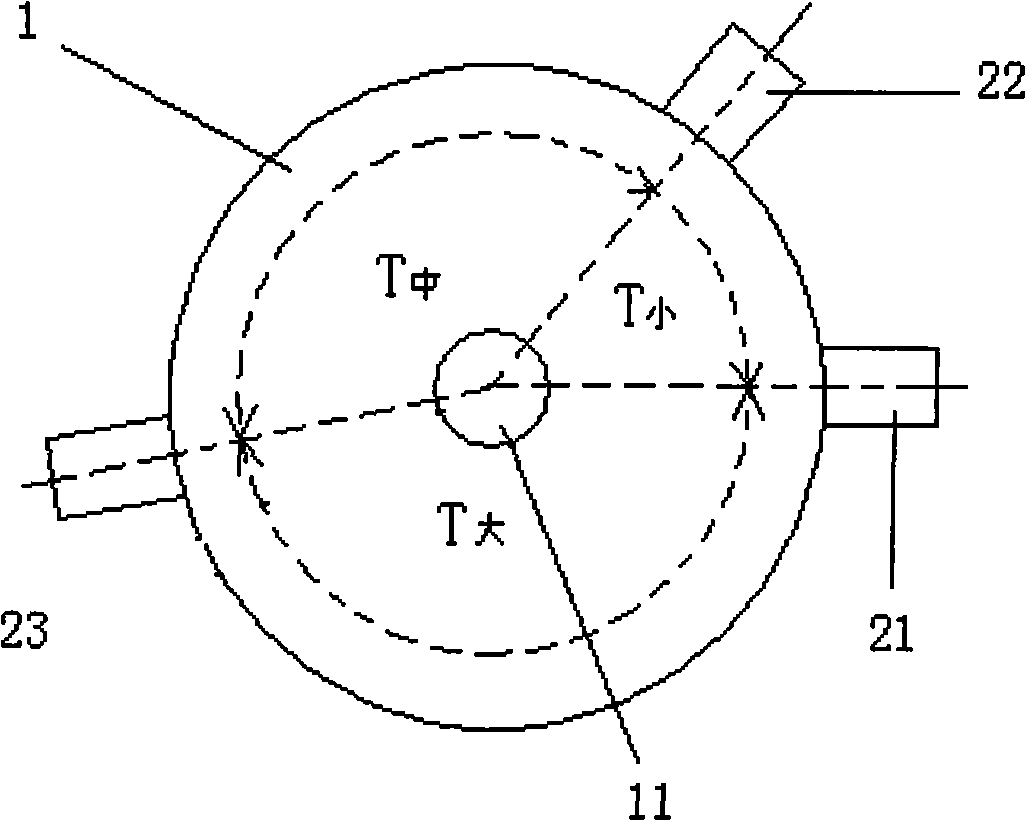

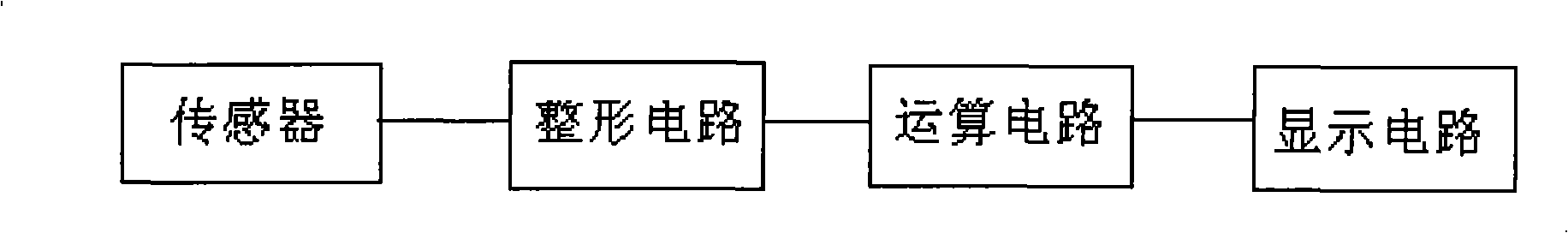

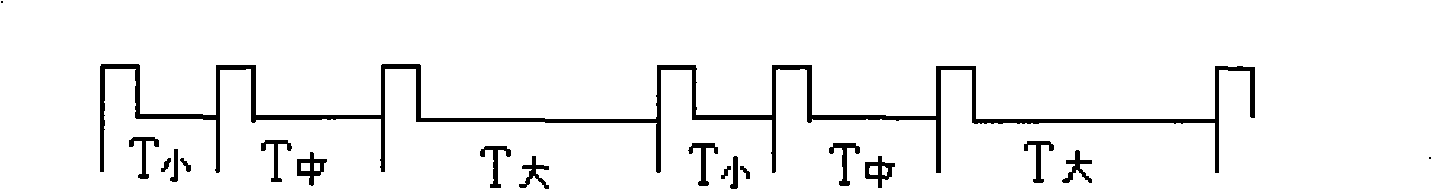

[0019] Such as figure 1 As shown, the present invention is provided with a turntable 1 installed coaxially with the rotating shaft on the rotating device, and sensor sensing sheets 21, 22, 23, sensing sheets 21 and 22 are arranged on different azimuth angles of the circumference of the rotating disk 1. Composed of T 小 Small azimuth; the T formed by the induction sheet 22 and the induction sheet 23 中 In the azimuth, the T formed by the induction sheet 23 and the induction sheet 21 大 Great azimuth. Azimuth T 小 中 大 . When the turntable rotates one circle, the sensor generates three different pulse signals corresponding to the installation angle of the induction sheet, the small interval time, the middle interval time and the large interval time, the pulse signal, through such as figure 2 The shaping circuit and arithmetic circuit in the electrical principle block diagram shown in the figure complete the calculation of the rotation speed, and the digital detection result is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com