Float liquid level meter with quick release mechanism

A buoy liquid level gauge and liquid pipe technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of relatively high installation position requirements, special tools required for disassembly and assembly, limited installation methods, etc., to achieve convenient maintenance and replacement, shock absorption The effect of improving performance and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

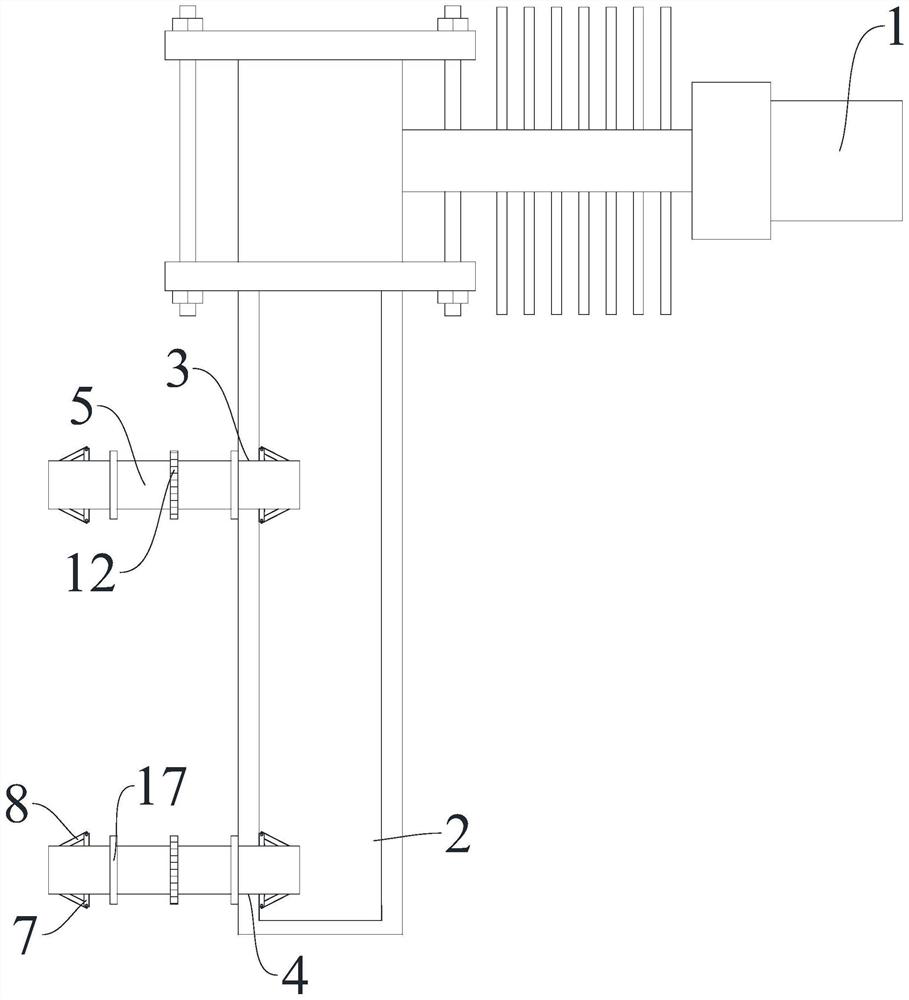

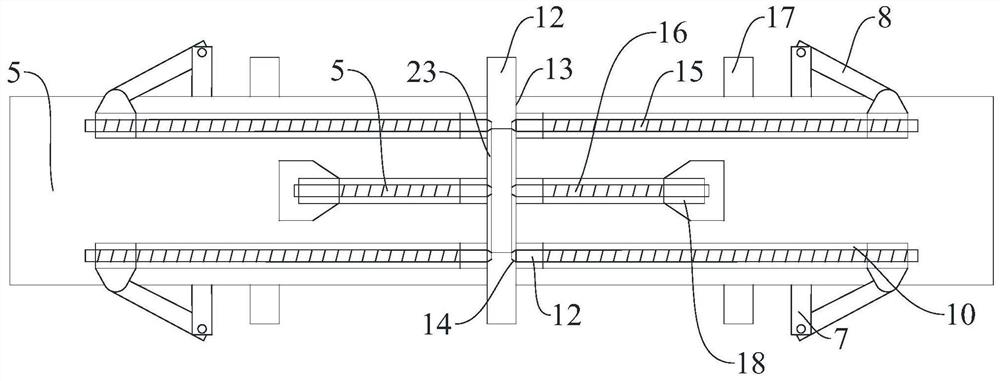

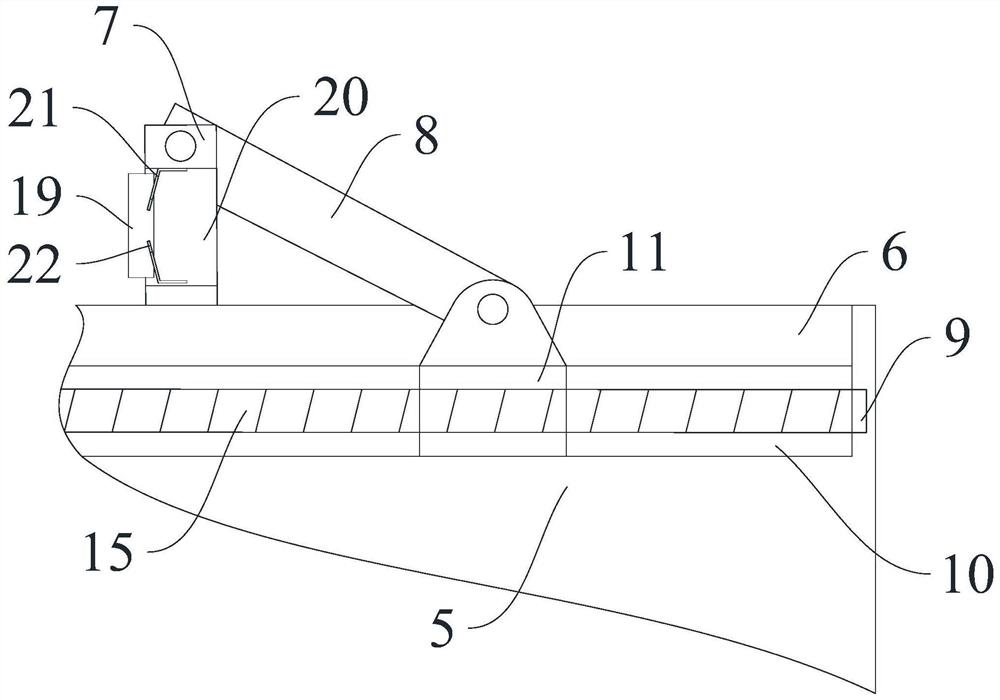

[0021] figure 1 , figure 2 with image 3 A floating cylinder level meter having a quick-release mechanism includes an electric floating cylinder level meter body 1 and a lateral guide cartridge 2, and a circular upper mounting hole 3 and a circle are provided on the outer side of the lateral guide cartridge 2. Fair assembly hole 4, the outer side surface of the lateral guide cartridge 2 is located on the circular upper assembly through hole 3 and the circular mounting hole 4 positions are provided with a cross-sided guide liquid tube 5, a cross-sided guide liquid Both lateral ends of the tube 5 have two lateral storage grooves 6, and the inner flipper squeezing rod 7 is attached to the inner flipper squeezing rod 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com