Visual inspection apparatus

A technology of appearance inspection device and observation device, which is applied to measurement devices, optical testing flaws/defects, instruments, etc., can solve the problems of inability to observe, unable to obtain images, and narrow observable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

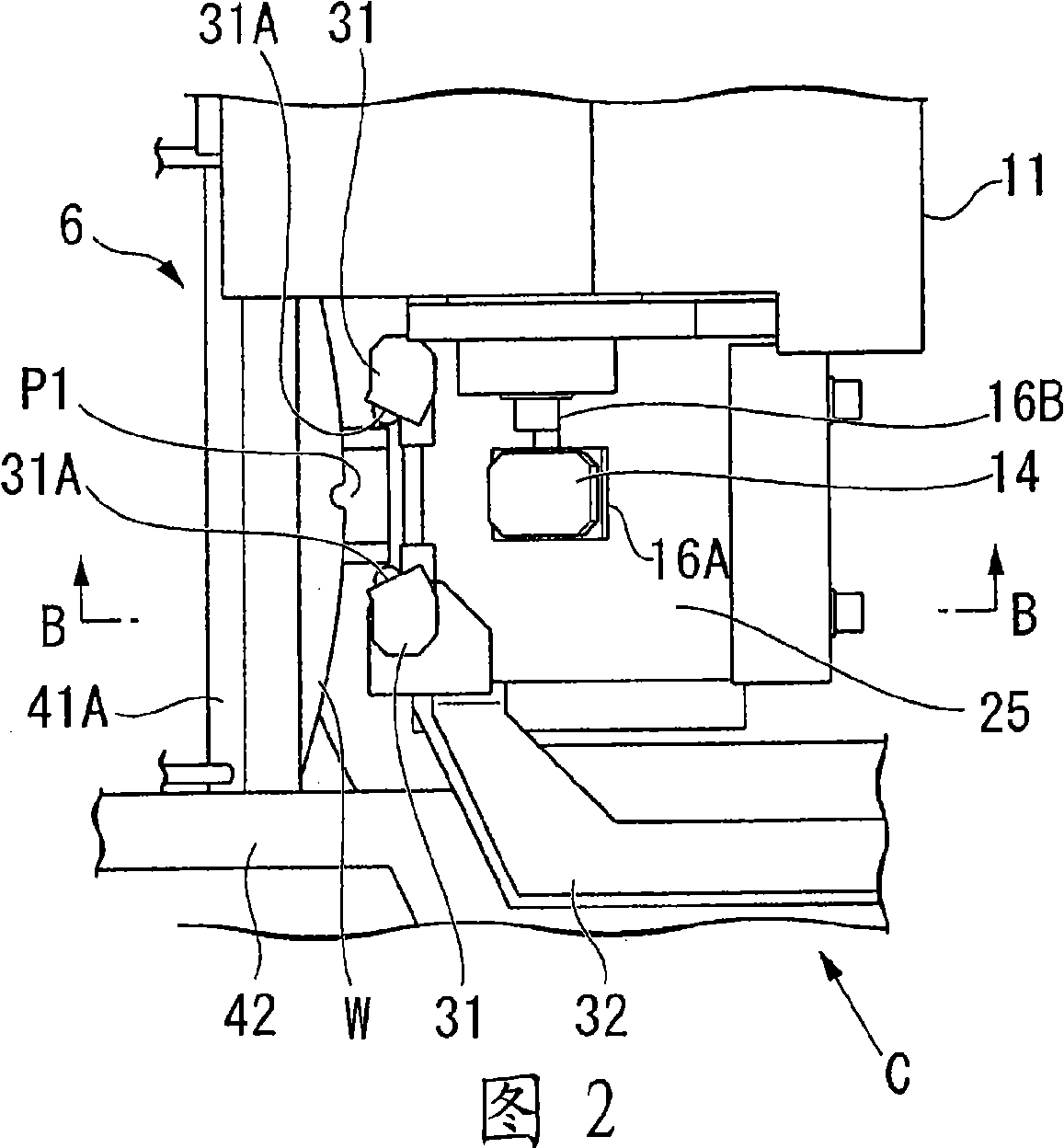

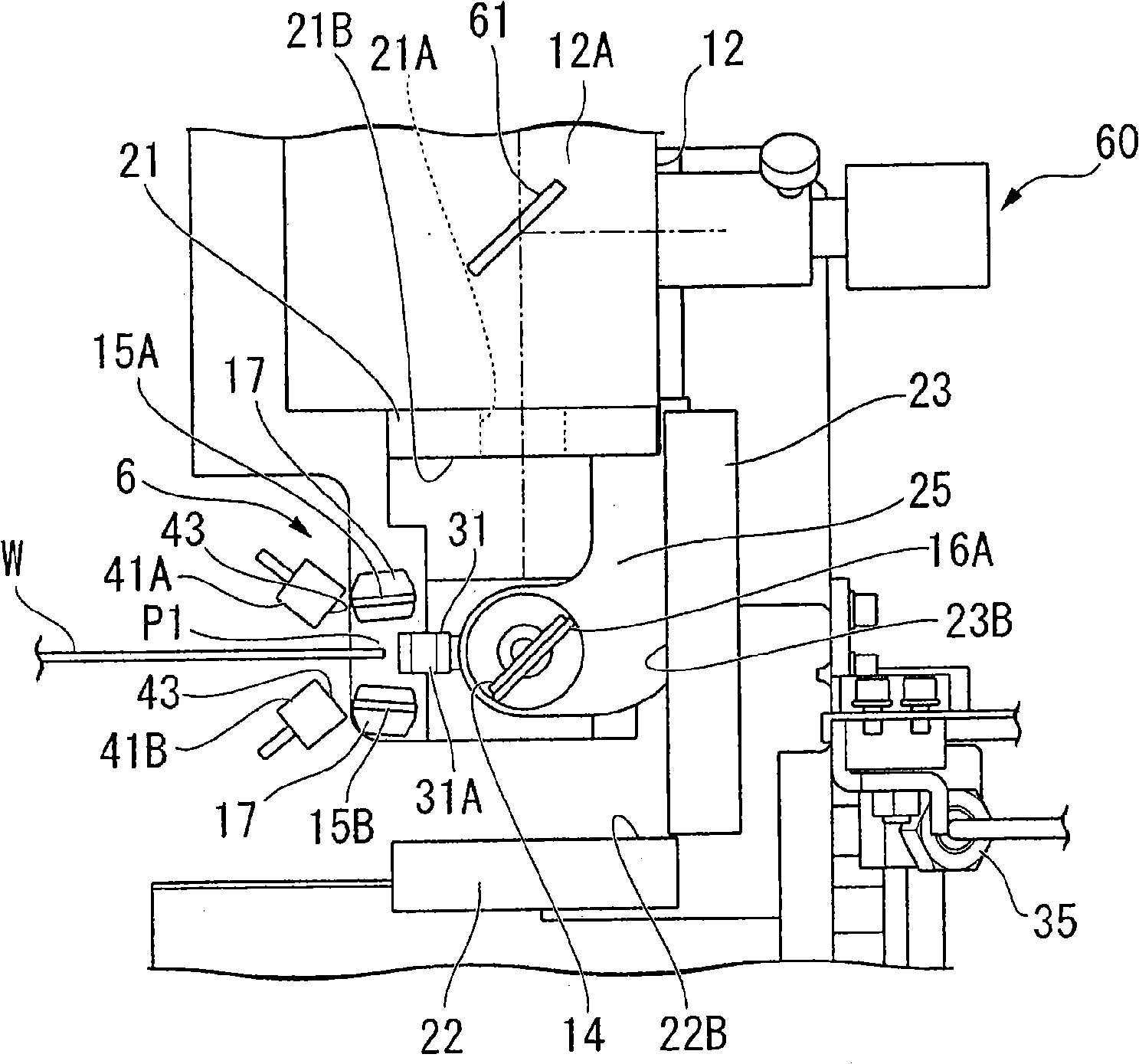

[0022] The best mode for carrying out the present invention will be described in detail with reference to the drawings. However, the present invention itself is of course not limited to these embodiments.

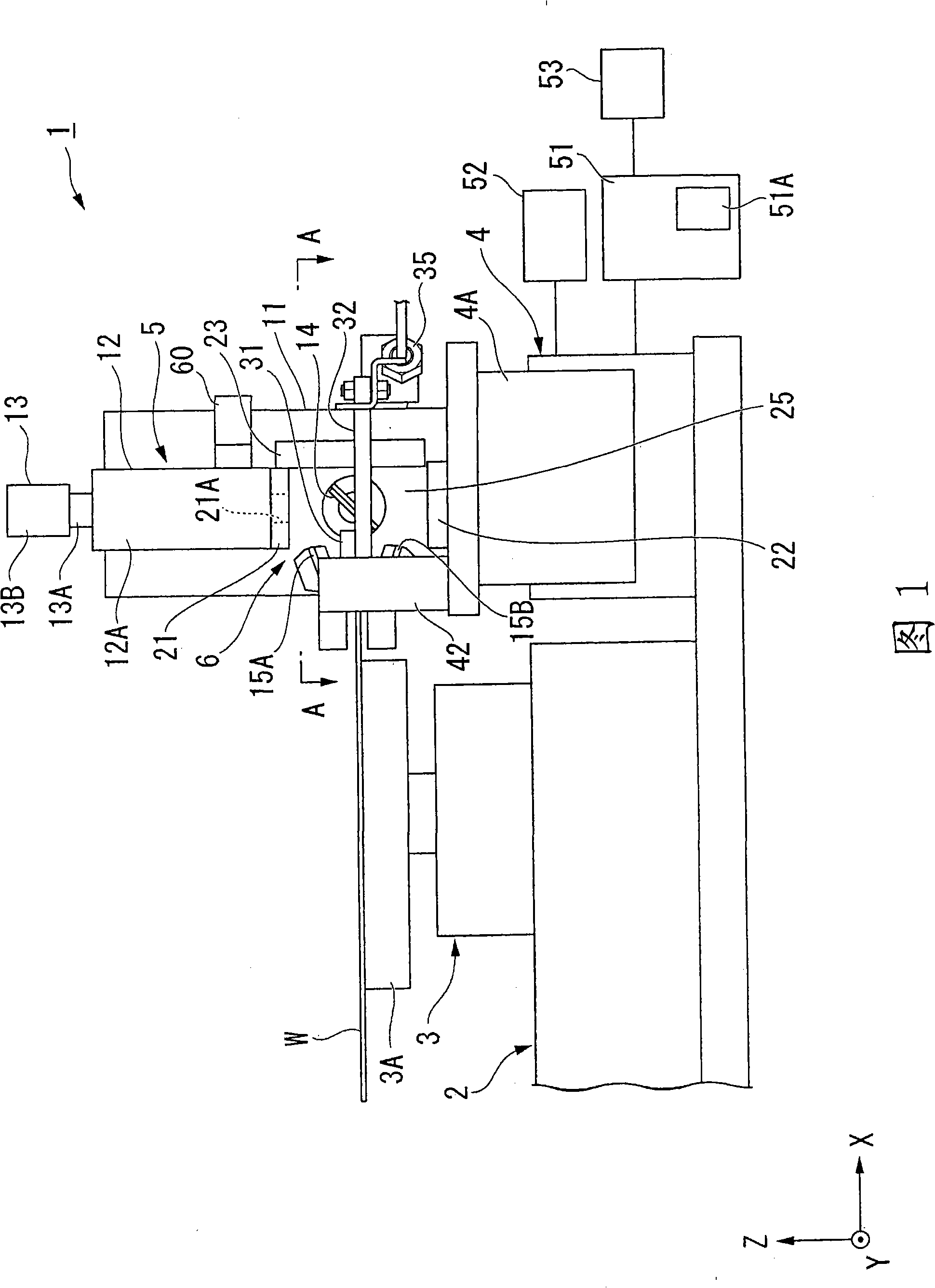

[0023] As shown in FIG. 1 , an appearance inspection apparatus 1 is provided with an XYθ stage 3 and a Z stage 4 on a base 2 for sucking and holding a wafer W which is a workpiece.

[0024] The XYθ stage 3 has a support portion 3A for supporting the wafer W, and a suction portion (not shown) that suction-holds the center of the back surface of the wafer W is provided on the support portion 3A. The XYθ stage 3 is configured so that the support portion 3A can move in two directions (X direction, Y direction) perpendicular to the horizontal direction and can rotate around a Z axis perpendicular to the XY direction. The drive of the XYθ stage 3 is controlled by a motor not shown. As the motor, a motor capable of precise positioning such as a servo motor or a stepping motor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com