Process and apparatus for treating exhaust gas of an internal combustion engine

A technology for internal combustion engines and equipment, applied in mechanical equipment, exhaust devices, engine components, etc., can solve problems such as difficulty in complying with limit values, and achieve the effect of uniform pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

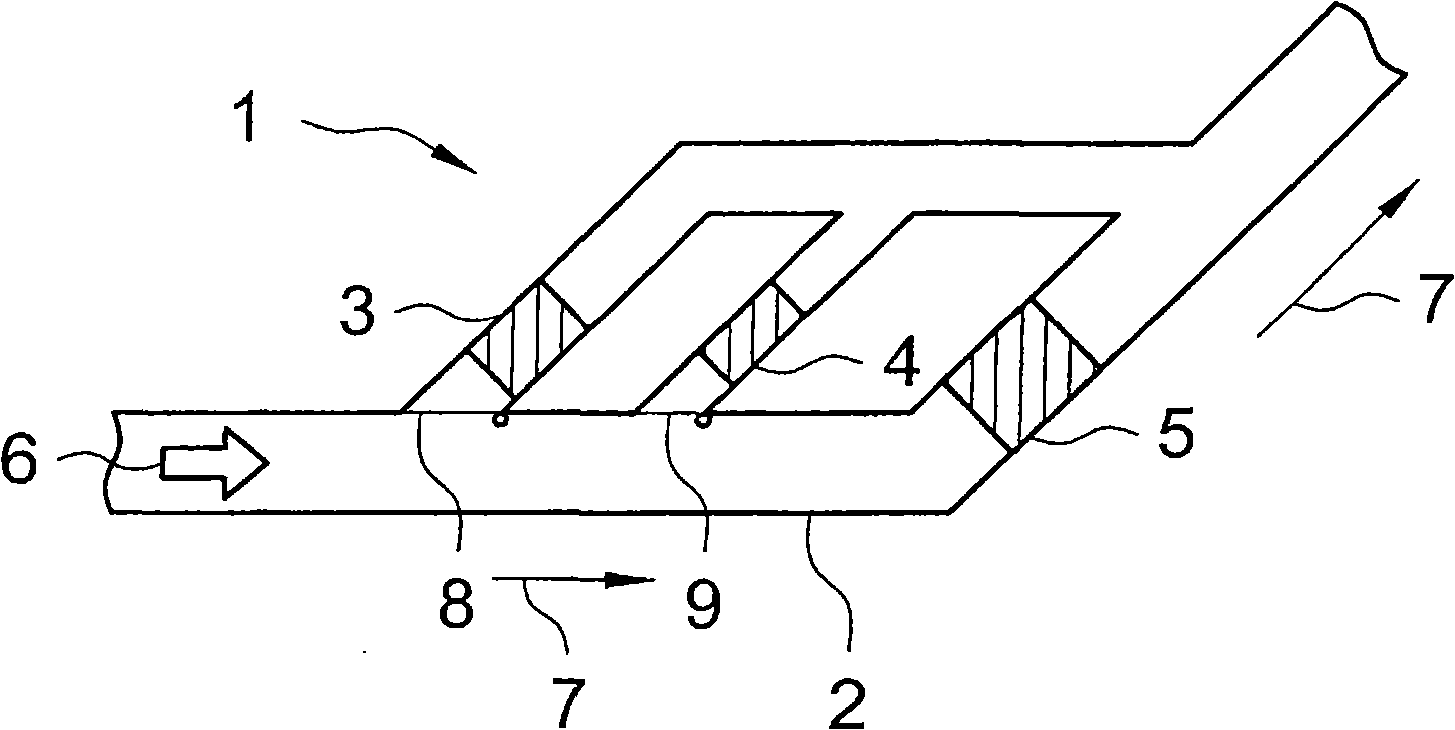

[0056] figure 1 A first exemplary embodiment of a device 1 according to the invention for treating exhaust gas 6 is shown schematically. The plant comprises an exhaust pipe 2 , a first module 3 and a second module 4 for treating the exhaust gas. In addition, an idle speed module 5 is also provided. An internal combustion engine, not shown, emits exhaust gas 6 which flows through the exhaust pipe 2 in a flow direction 7 . The first module 3 for treating exhaust gas is associated with a first connecting device 8 . In this first embodiment, the connecting device 8 comprises a pivotable flap by means of which the module 3 can be connected to the exhaust pipe 2 so that at least a part of the exhaust gas 6 can flow through the module 3 . Correspondingly, a second connecting device 9 is provided, which is associated with the second module 4 for treating the exhaust gas.

[0057] Said idle module 5 is not equipped with connection means, because even when the first connection means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com