Method for confirming ink-supplying amount of printing machine

A technology for printing presses and ink supply, which is applied in printing presses, general parts of printing machinery, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

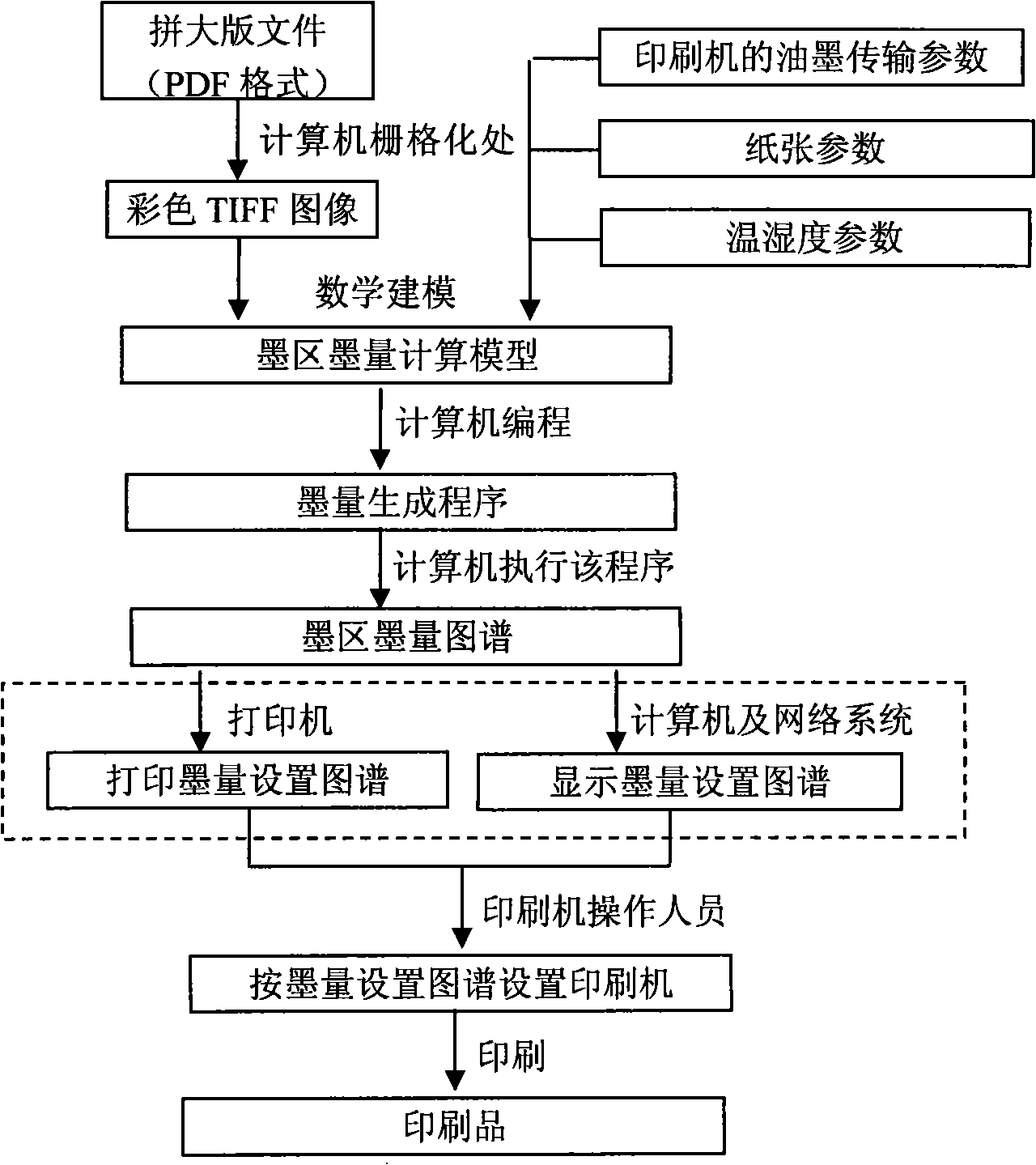

Method used

Image

Examples

Embodiment

[0049] 1. Printing conditions

[0050] Printing machine: Heidelberg CD102; Paper: Jindong brand (157g) coated paper; Ink: Tiens brand; Temperature: 25°C; Humidity: 60%;

[0051] 2. Prepare the manuscript for calculation

[0052] First, convert the files generated after imposition into PDF format, and then use Photoshop software to convert them into images in TIFF format with a resolution of 81.28DPI, which is used as the original data for ink volume calculation;

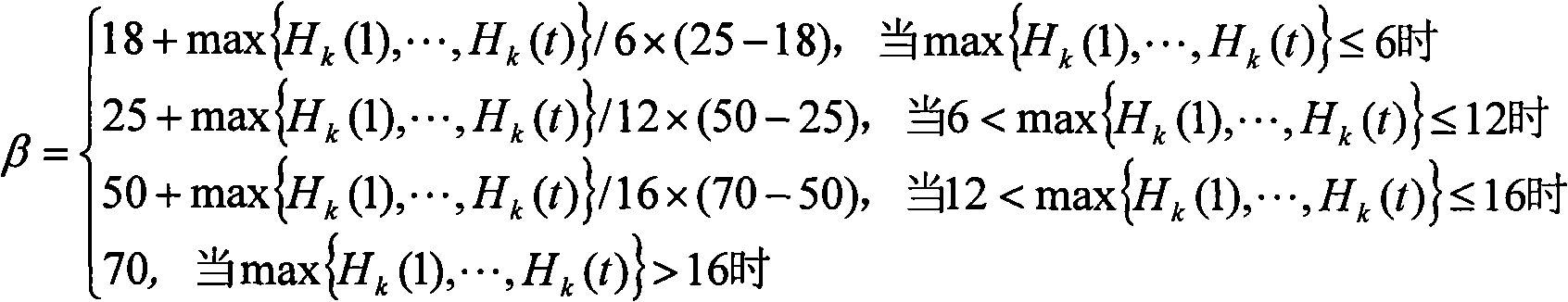

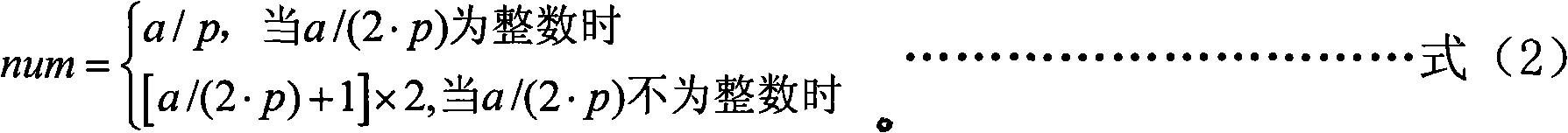

[0053] 3. Calculate the ink volume value of the ink area

[0054] Start the ink volume calculation software in the ink area, first set the initial conditions for the calculation of the ink volume in the ink area according to the actual conditions. The image resolution is 81.28dpi, and the maximum layout is 1030mm. %, and then use the ink volume calculation model to read in the original, and use the calculation model to generate ink volume data. The computer steps performed and the calculated values are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com