Indoor gas pipeline leakage protecting method and apparatus

An internal gas and pipeline technology, applied in the field of indoor gas pipeline leakage protection methods and devices, can solve problems such as slow gas leakage, safety accidents, and no indoor gas pipelines, and achieve reliable safety protection and reliable leakage protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

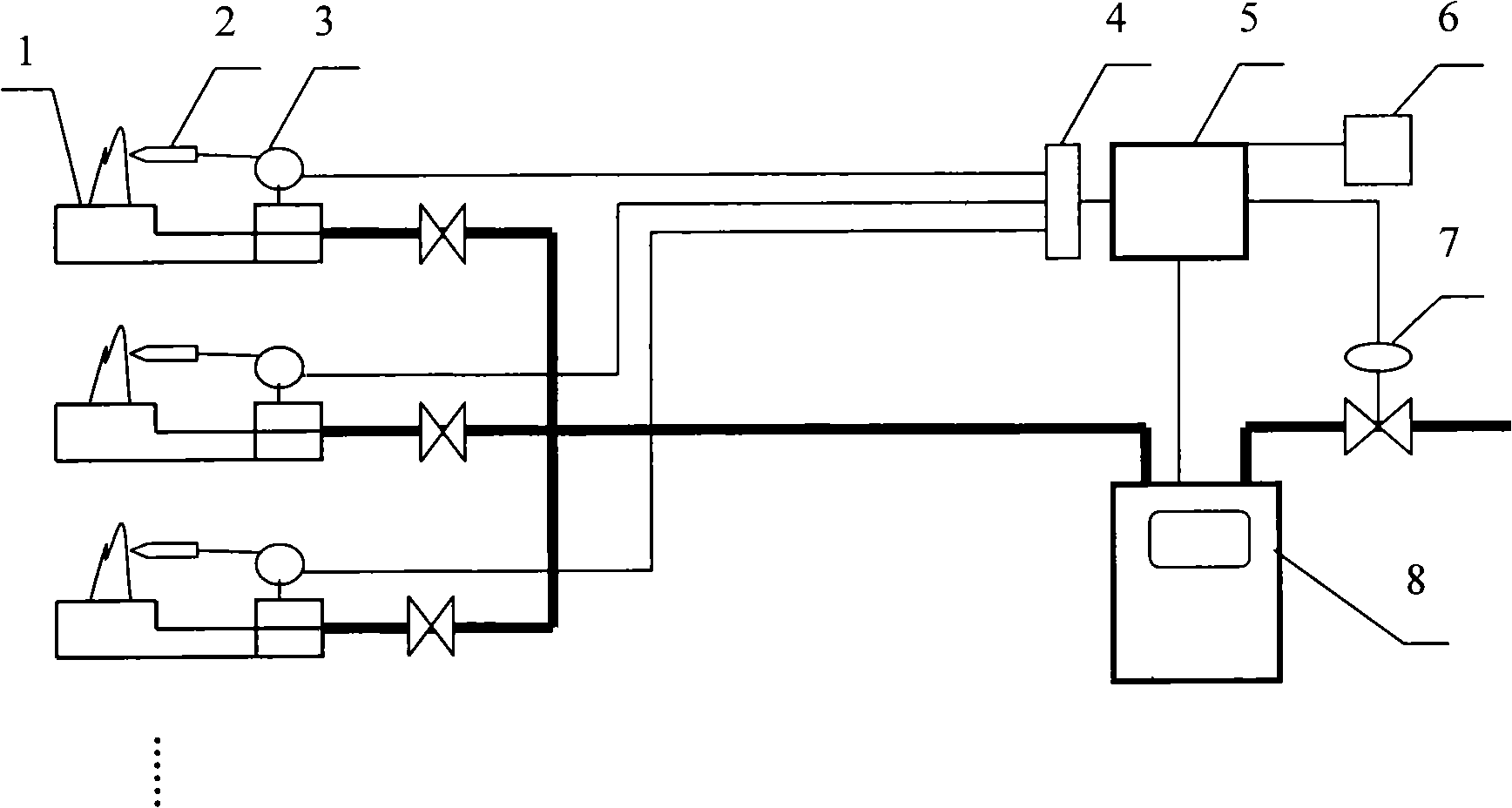

[0017] Such as figure 1 As shown, the indoor gas pipeline leakage protection device provided by the present invention includes a flame signal acquisition module 4 , a control circuit 5 , a normally closed solenoid valve 7 , an alarm 6 and a flow signal acquisition module 8 . In this example, the flame signal acquisition module 4 uses a potential signal detection unit.

[0018] The flow signal acquisition module 8 is installed on the gas inlet pipe, and is used to obtain the flow information on the gas inlet pipe, which may be the output signal of the gas meter or the signal provided by other gas flow sensors.

[0019] The potential signal detection unit is connected to the input end of the solenoid valve 3 for flameout protection of the gas appliance through wires, and obtains the potential signal of the solenoid valve 3 to obtain the working state information of the gas appliance. The normally closed solenoid valve 7 and the flow signal acquisition module 8 are installed on ...

Embodiment 2

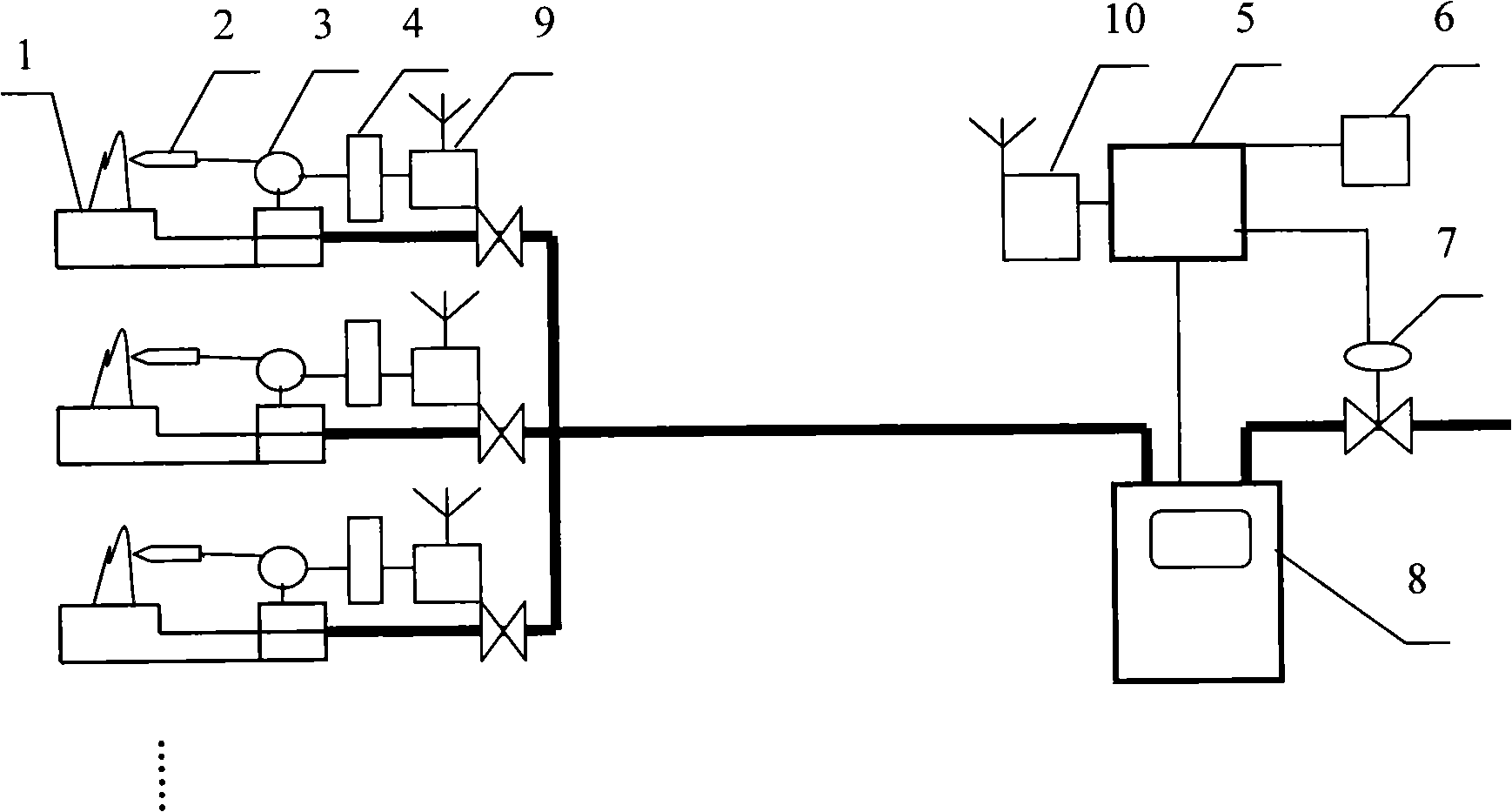

[0024] Such as figure 2 As shown, will figure 1 The wired transmission mode of the flame detection signal in the shown system is changed to wireless transmission. For this reason, a dedicated data transmission module 9 is installed on each gas appliance, and the flame detection signal is sent out in an encrypted manner. The burning appliance uses the same encrypted signal, and a data receiving module 10 corresponding to the data transmission module 9 is also installed in the control circuit, which is specially used for receiving predetermined encrypted signals.

[0025] This system does not require indoor wiring, which is more suitable for the transformation of old users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com