System and method for designing mold by cooperation

A collaborative design system and mold technology, applied in transmission systems, calculations, special data processing applications, etc., can solve the problems of time-wasting, low efficiency, and difficulty in modifying image files in image file transmission, so as to shorten the design time, facilitate modification, The effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

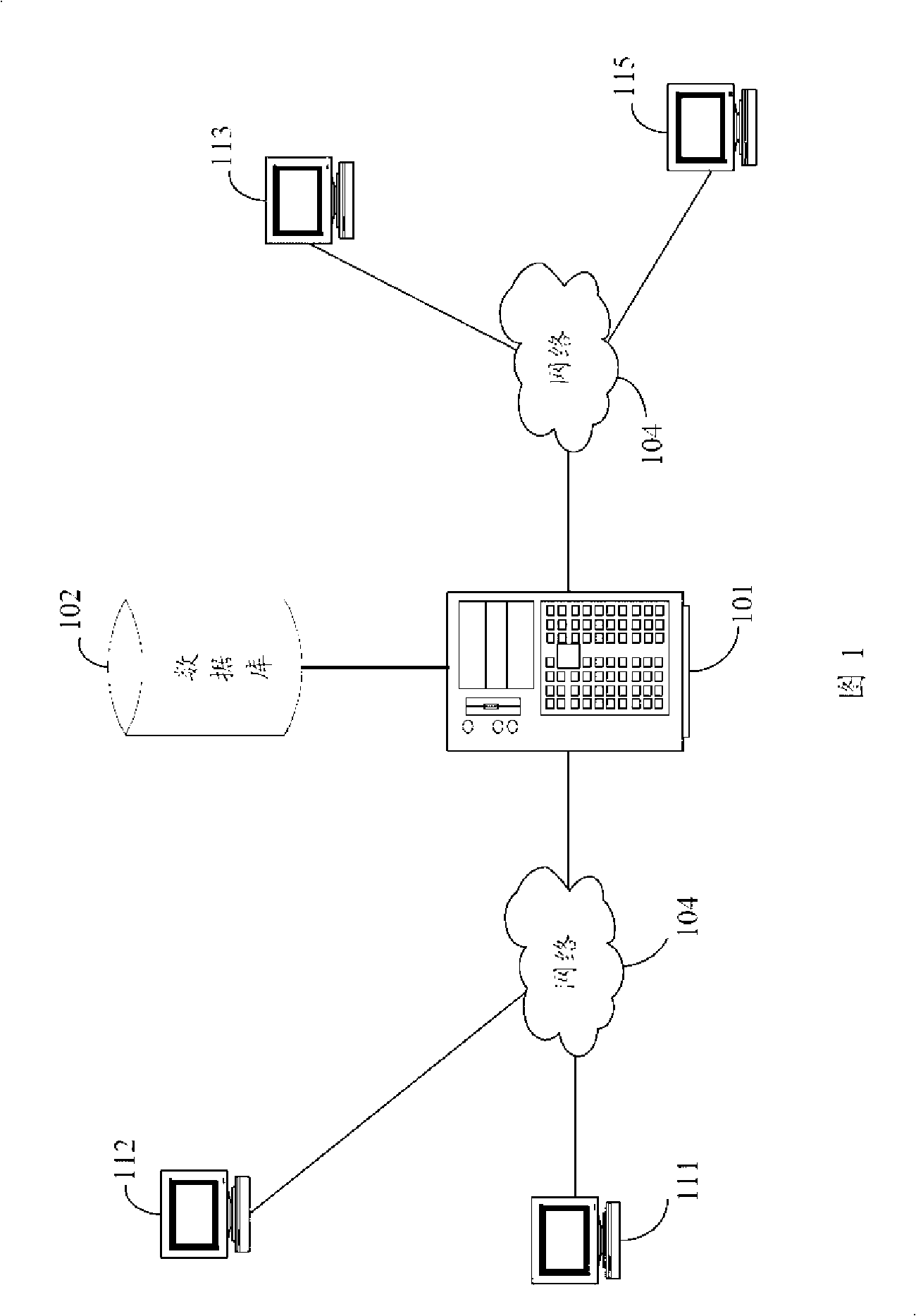

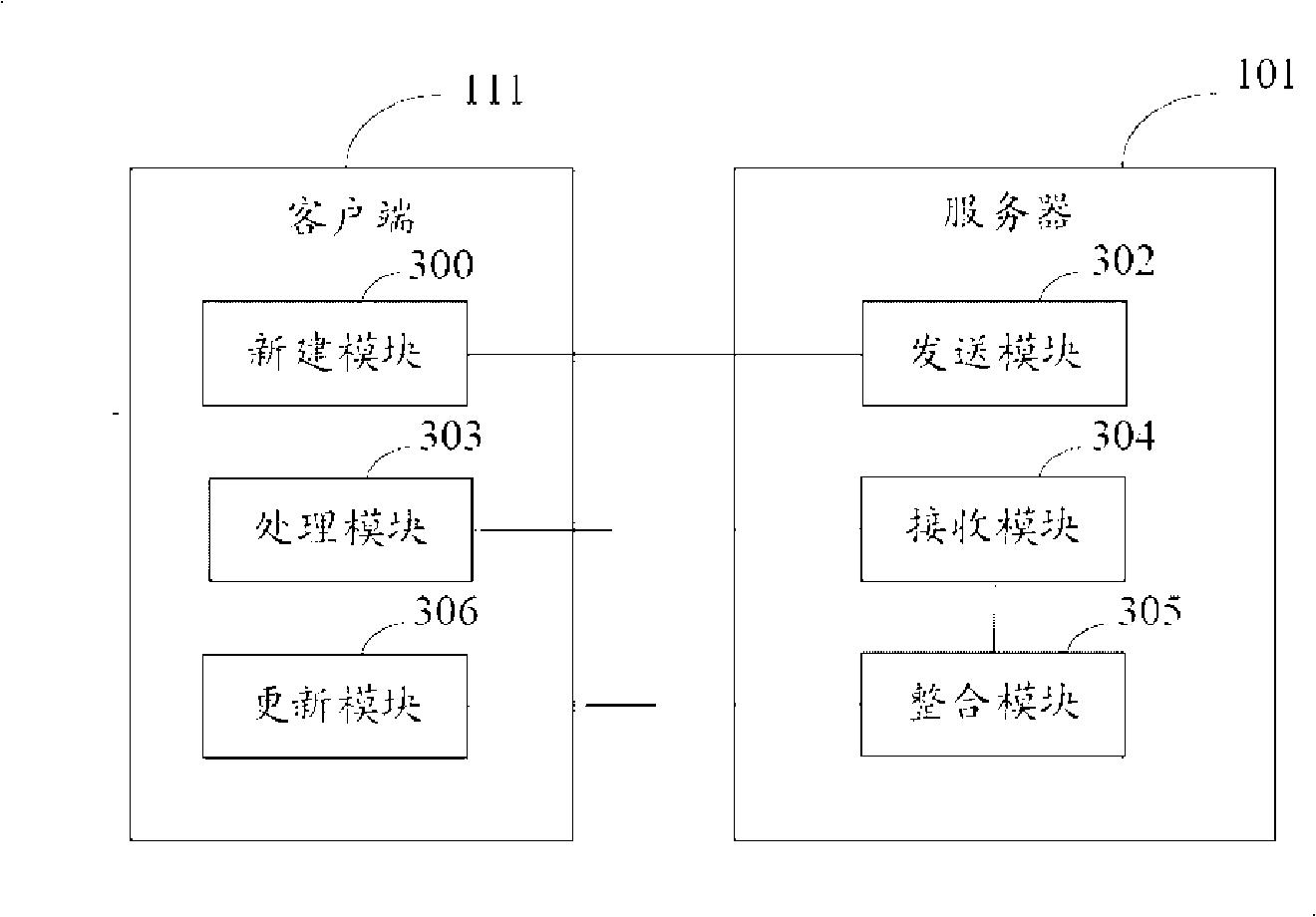

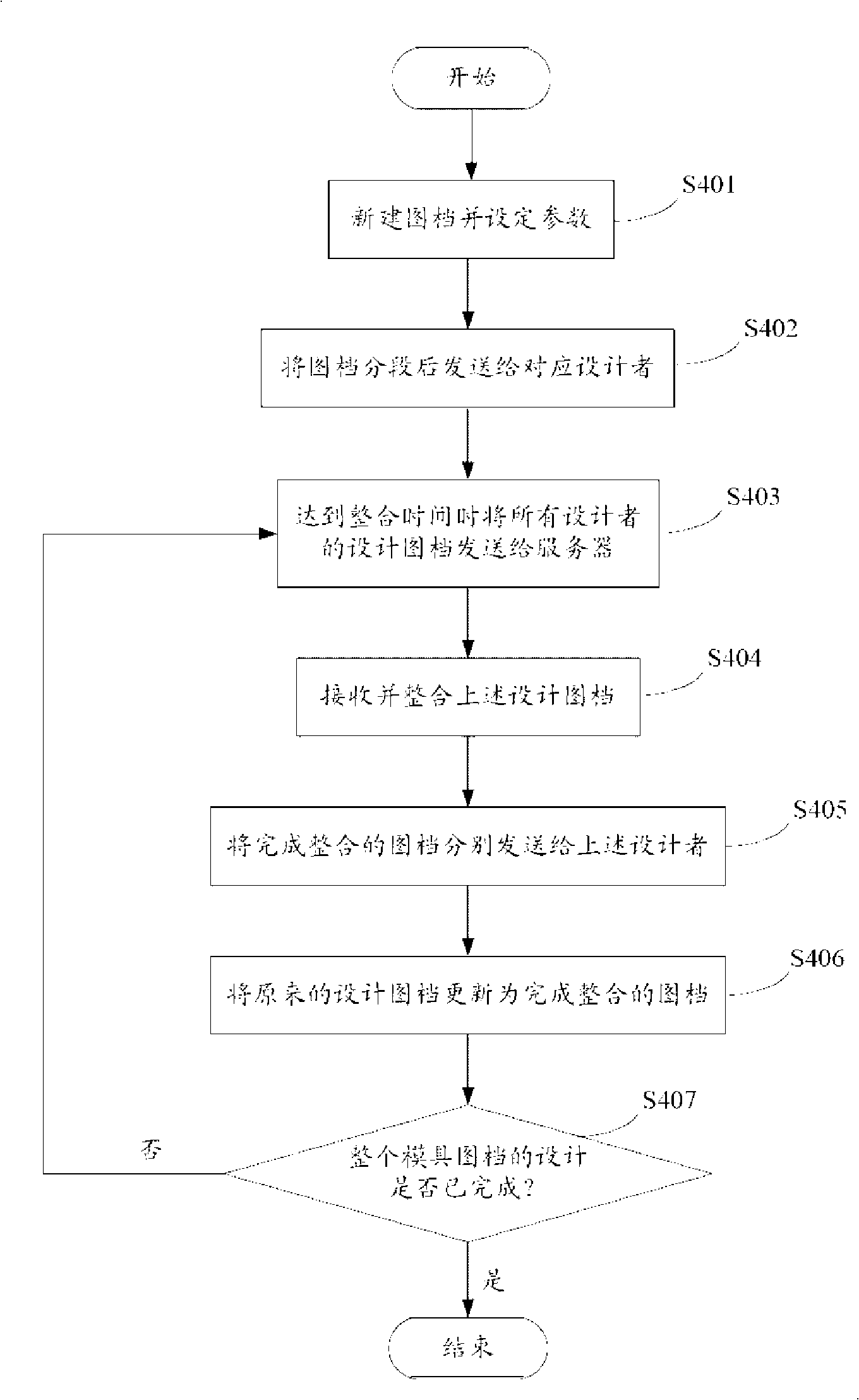

[0014] Referring to Fig. 1, it is a schematic view of the operating environment of the mold collaborative design system of the present invention. The mold collaborative design system is installed in a master-slave architecture (Server / Client). The master-slave architecture includes a server 101, a database 102 and a plurality of distributed clients (only 111, 112, 113 and 115 are shown). The above-mentioned devices are connected through the network 104, so as to realize cooperative work among the devices.

[0015] Wherein, the clients 111, 112, 113 and 115 are the interfaces of the system application, which are responsible for providing an interactive user interface, so that multiple designers can collaboratively design the mold drawings.

[0016] Described network 104 is a kind of electronic network, and it can be intranet (Intranet), Internet (Internet) or other network based on TCP / IP (Transport Control Protocol / Internet Protocol, Transmission Control Protocol / Internet Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com