Hard centre sweets processing technique and products thereof

A processing technology and technology of hard candy, applied in the confectionery industry, confectionery, food science and other directions, which can solve the problems of single taste and inability to produce center-filled candies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

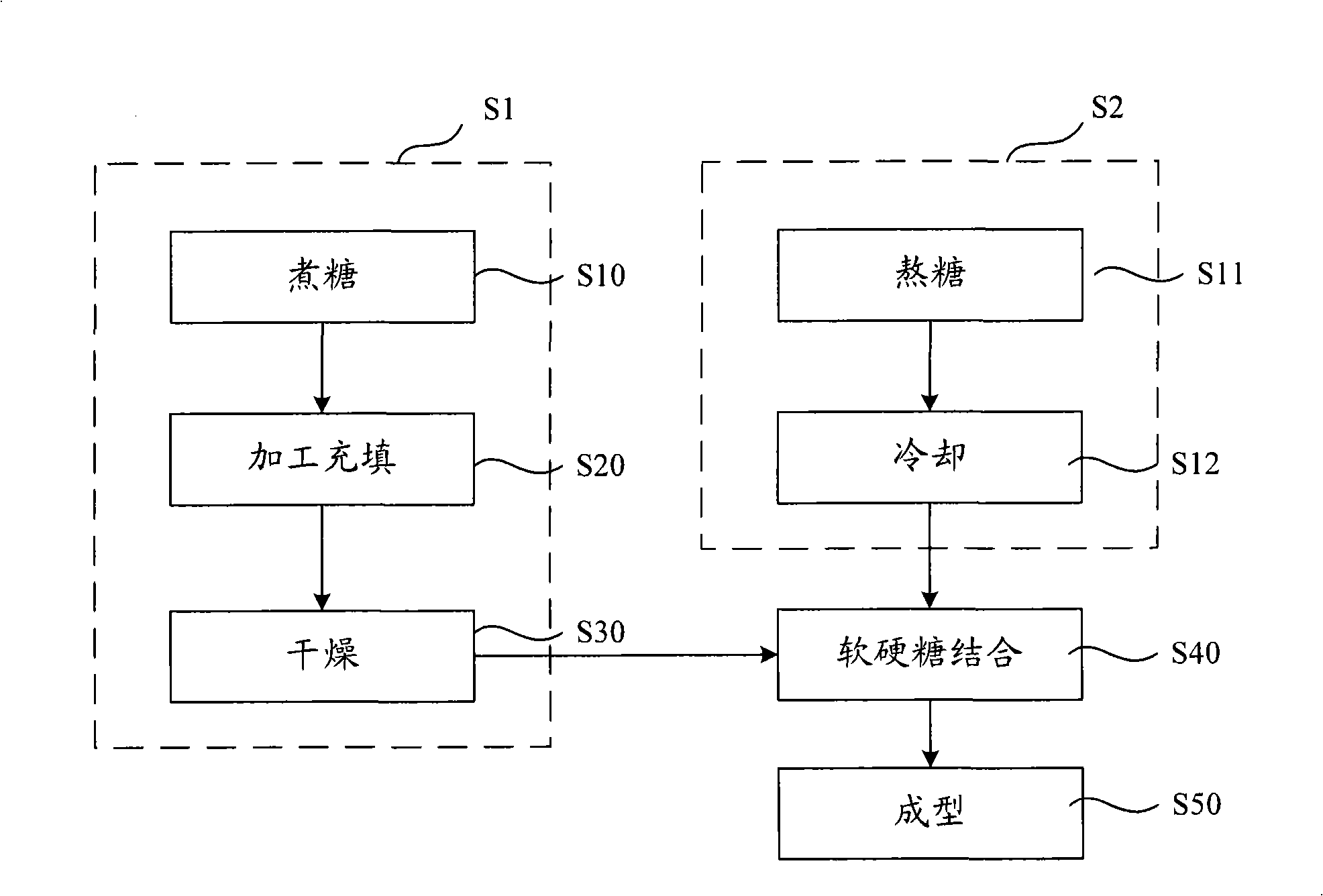

[0023] The process of processing hard sandwich candy is as follows: figure 1 As shown, the soft candy is processed in step S1, and the hard candy is processed in step S2. In the following description, the amount of each raw material is given according to the weight percentage of the sum of the weight of raw materials in steps S1 and S2.

[0024] Step S1 includes steps S10-S30. In the sugar boiling step S10, first prepare 32-35% water and heat it; in the process of water heating, add the main raw materials into the hot water to dissolve, the main raw materials include first-grade granulated sugar, pectin, citric acid The amounts of sodium and sodium hexametaphosphate are 30-33%, 1.7-1.9%, 0.14-0.15%, and 0.1-0.12% respectively; after continuing to heat to boiling, add 28-30% maltose syrup according to weight percentage; Reheat to boiling, until the sugar content of the solution is between 75Brix and 80Brix, add 0.28-0.3% of sour taste such as sodium citrate and 0.1-0.2% of ess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com