Processing method and apparatus for nonmetal object surface using hot melting adhesive glue powder

A technology for object surface and treatment method, which is applied to the surface treatment of non-metallic objects, and a processing device for realizing the above method. Hot-melt adhesive powder is used in the field of surface treatment of non-metallic objects, which can solve the problems affecting health and birth, human hazards, etc. problems, to save energy, avoid pollution, and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

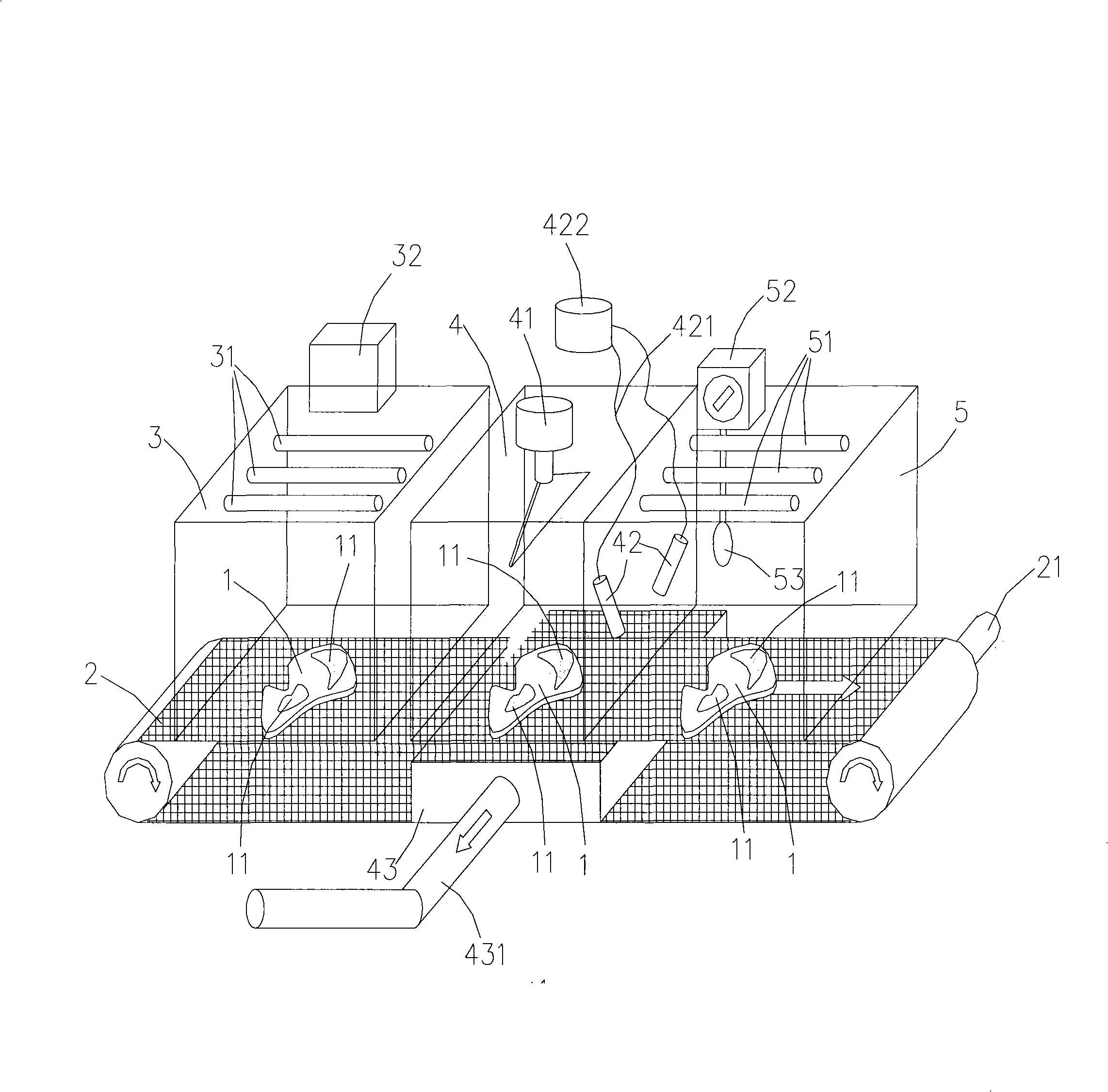

[0017] For the technology, means and effects adopted by the above-mentioned processing method and processing device of the present invention, a preferred embodiment is given and described in detail as follows in conjunction with the accompanying drawings:

[0018] As shown in the accompanying drawings, the present invention provides a treatment device and a treatment method for hot-melt adhesive powder sticking to the surface of a non-metallic object, the steps of which include the following:

[0019] a. Apply cleaning agent: apply cleaning agent (commercially available) to the surface of the non-metallic object to be adhered with a brush or spray gun.

[0020] b. Smear conductive liquid: use a brush or a spray gun to smear conductive liquid (available on the market) on the above-mentioned area 11 to be adhered, and place the shoe part 1 coated with conductive liquid on the grid conveyor belt 2, The transmission speed of the conveyor belt 2 can be adjusted by a speed-regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com