Homeostasis center supporting device

A central support and steady-state technology, applied in the field of support machinery, can solve problems such as reducing sealing performance, damage to hydraulic equipment, and degradation of sealing performance of hydraulic cylinders or cylinders, so as to prolong service life, overcome unbalanced forces, and reduce processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

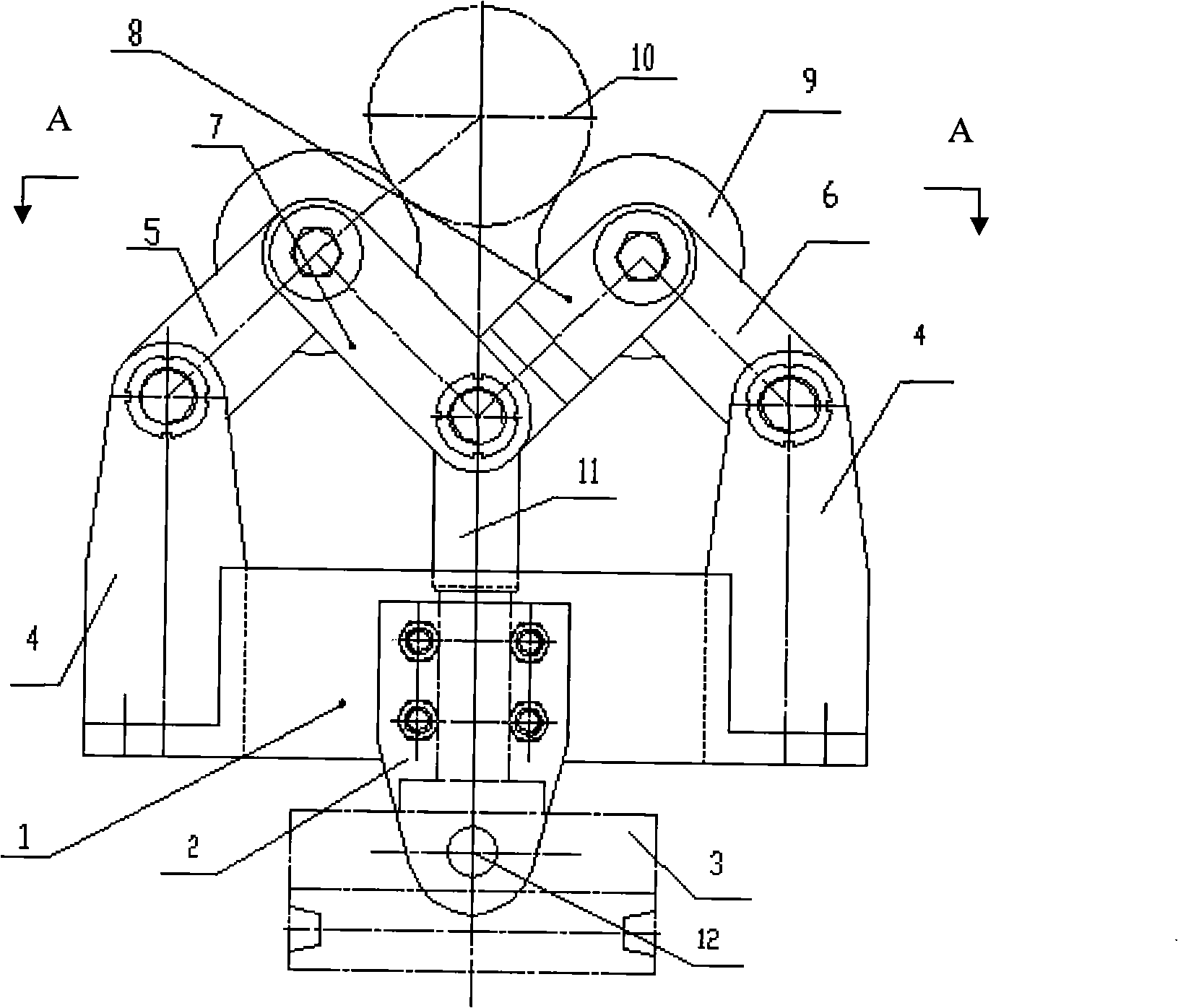

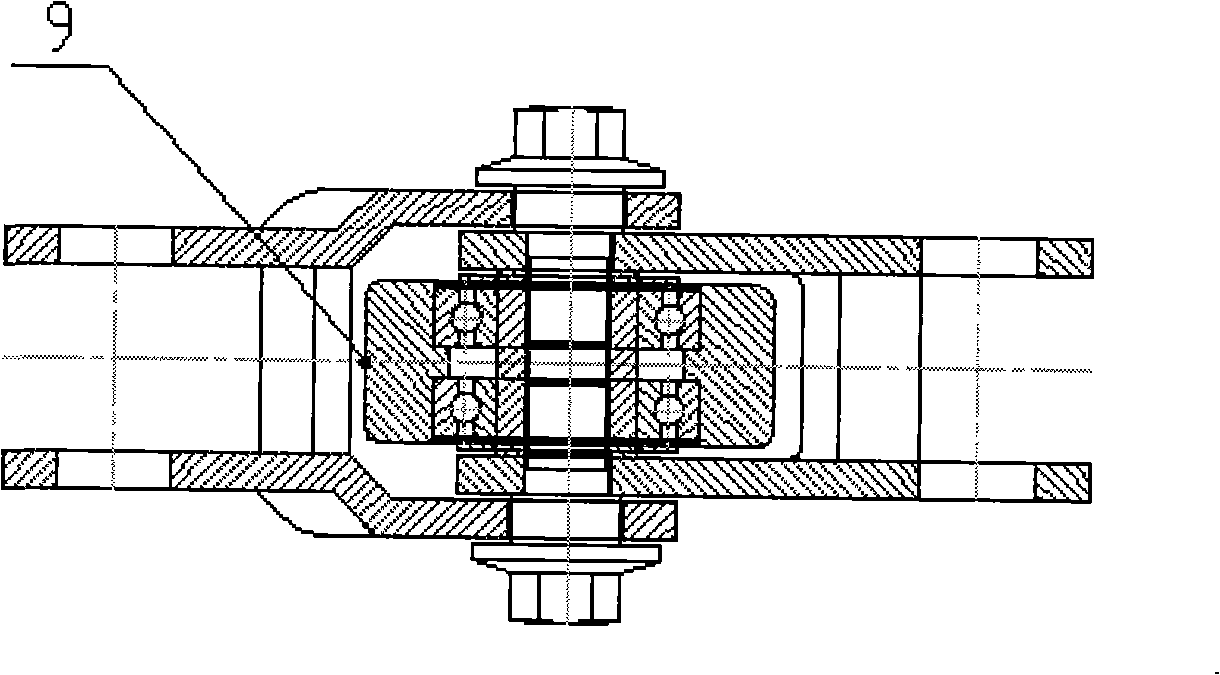

[0015] join figure 1 , The self-stable central support device of the present invention is mainly composed of a fixed seat, rollers, a support structure and hydraulic equipment.

[0016] The middle part of the fixed seat 1 is a cube platform, the left end of the platform is provided with a left columnar body 4, the right end of the platform is provided with a right columnar body 4, and the left and right two columnar bodies are identical double sheet structures . The two columns are of equal height. The fixing seat is made of strong metal material. In order to ensure the stability of the whole equipment, the fixing seat should be directly or indirectly connected with the concrete foundation.

[0017] Hydraulic equipment is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com