Liquid ejecting apparatus and method of controlling same

A spraying device and liquid technology, applied in the direction of inking device, printing, etc., can solve the problem of enlargement and achieve the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0022] (1) Configuration of this embodiment

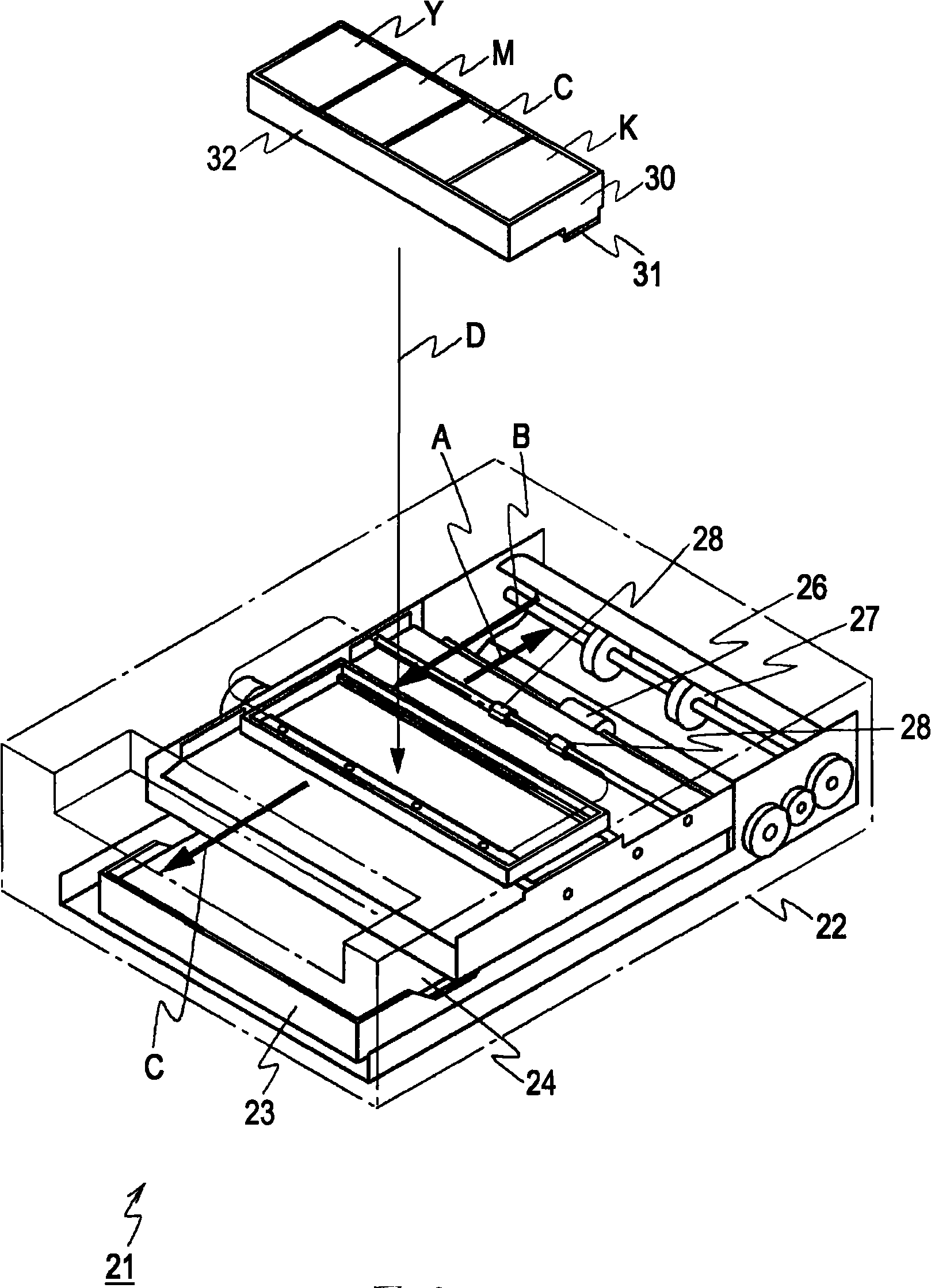

[0023] figure 2 is a perspective view showing the printer 21 according to the first embodiment of the present invention. The printer 21 is a line printer. It is integrally formed in such a manner as to be equipped in a rectangular housing 22 , and a paper tray 23 equipped with printing paper 24 is installed from a slot-type inlet formed in the front side of the housing 22 .

[0024] Here, when the paper slot 23 is installed in the printer 21, a predetermined mechanism causes the printing paper 24 to be pressed by the paper conveying roller 26, and due to the rotation of the paper conveying roller 26, the printing paper 24 is conveyed toward the side opposite to the paper slot 23, as indicated by an arrow. Indicated by A. In the printer 21, the reverse roller 27 is disposed on the side where the paper is conveyed, and due to the rotation of the reverse roller 27, the conveying direction of the printing paper 24 is shifted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com