Twisting double anti-forge wine bottle cap

A wine bottle cap and double technology, which is applied in the field of twist-off double anti-counterfeiting wine bottle caps, can solve the problems of reducing product quality, prone to scratches, complicated assembly process, etc. The effect of artistic taste

Active Publication Date: 2008-10-15

浙江润达包装科技有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The opening force of the aluminum torsion break point produced is inconsistent, and the surface connection point is higher than the surface plane after the twist is broken, which is prone to scratches and hand injury accidents

The connection between the cover and the lower sleeve is also welded by ultrasonic wave, which is easy to generate garbage, which brings great difficulty to the dust blowing process and reduces the quality of the product

And there is no anti-counterfeiting effect inside, the structure is single and unreasonable, and the assembly process is complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

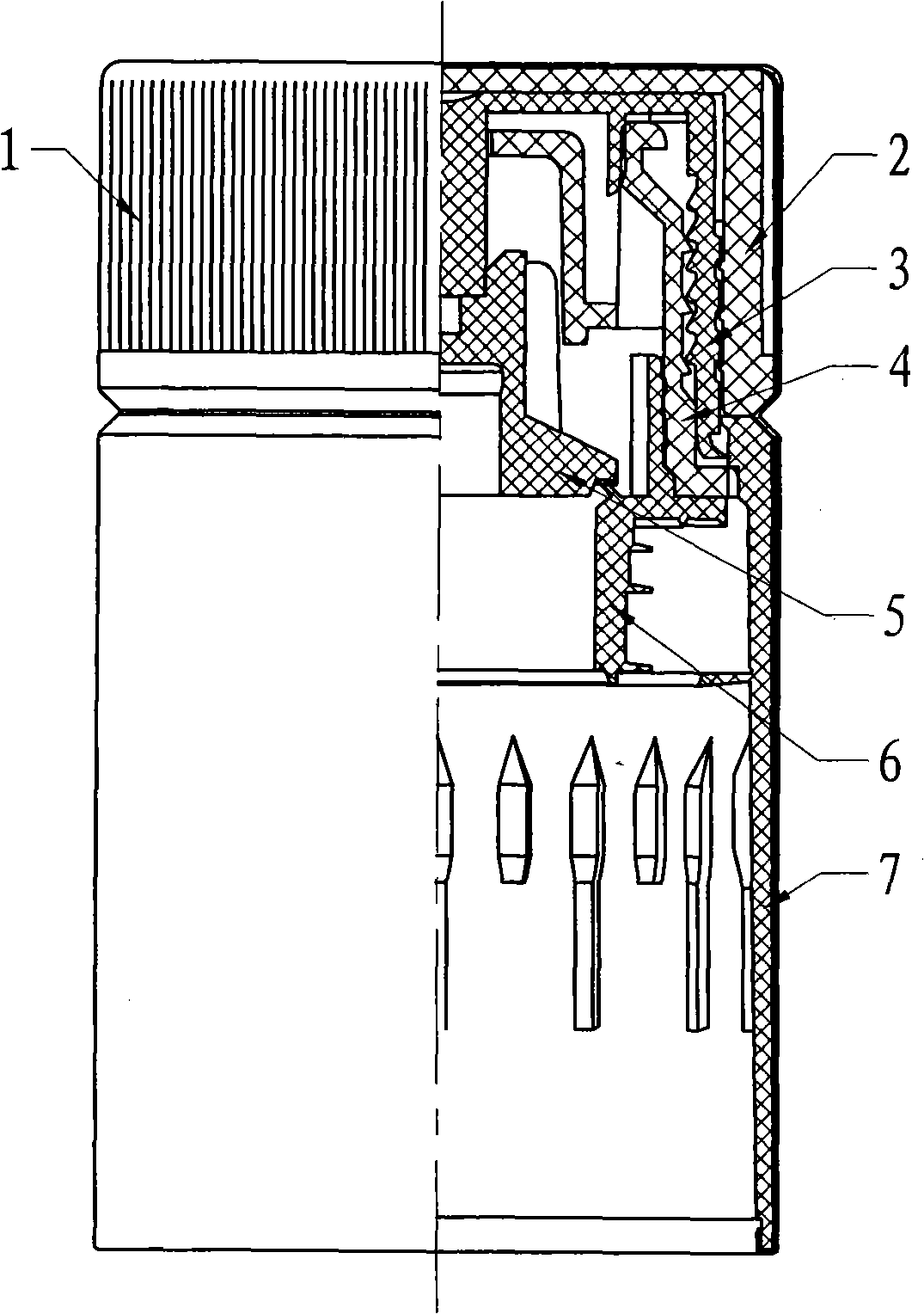

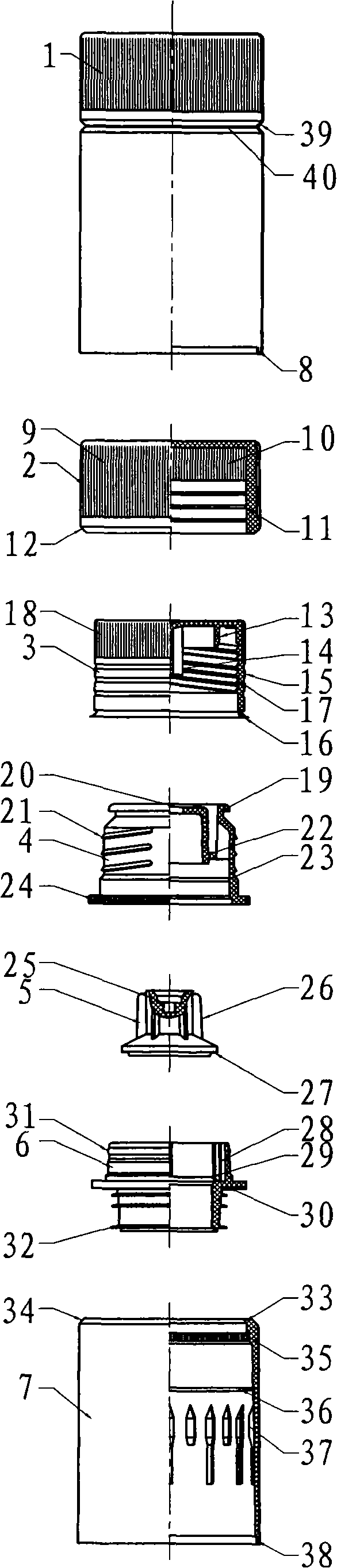

The invention relates to a twist-off-type double anti-fake wine bottle cap and belongs to the technology field of fluid container protection and repeated use prevention of the seal cap manufacture. The bottle cap mainly comprises an aluminum sleeve (1), and an upper cover (2), an inner upper cover (3), a connecting cover (4), a valve (5), an inner plug (6), a lower sleeve (7), etc., which are sequentially connected from top to bottom and arranged in the aluminum sleeve (1); wherein, a groove (39) and a twist breakpoint (40) are formed by rolling inwards of the middle part of the aluminum sleeve, a rotary retaining tooth (10) and a location-limited muscle (11) are arranged in the upper cover; a rotary retaining tooth (18) and an inner screw thread (17) are arranged and a location-limited groove (15) is formed on the inner upper cover; an external screw thread (21) is arranged on the connecting cover; a pop-up port (33) matched with an elastic ring sheet (16) of the inner upper cover (3) is arranged in the lower sleeve. The novel structural forms such as the adoption of internally rolling the middle part of the aluminum sleeve to form the groove and embedding the elastic ring sheet at the bottom of the connecting cover into the pop-up port of the lower sleeve, thus achieving the internal and external double anti-fake effect by rotating and twisting off the external groove and propping and damaging the internal elastic ring sheet.

Description

Twist off double anti-counterfeiting wine bottle cap technical field The invention relates to a twist-off double anti-counterfeiting wine bottle cap, which belongs to the technical field of liquid container protection and sealing cap manufacturing for preventing repeated use. Background technique The existing aluminum twist-off type wine bottle cap has adopted the straight plane structure of the aluminum sleeve to carry out the surface hard treatment of aluminum oxidation. The resulting aluminum torsion breaking point has inconsistent opening force, and the surface connection point is higher than the surface plane after twisting, which is prone to scratches and hand injuries. Ultrasonic wave welding is also adopted between the connection cover and the lower sleeve, which is easy to generate garbage, which brings great difficulty to the dust blowing process and reduces the quality of the product. And there is no anti-counterfeiting effect inside, the structure is single an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65D51/18B65D41/34B65D47/06B65D55/02

Inventor 徐荣贵

Owner 浙江润达包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com