Hook and hoisting machinery with the hook

A technology of hoisting machinery and hooks, applied in the field of hoisting machinery, can solve problems such as wasting manpower, low work efficiency, and falling, and achieve the effect of simple and convenient operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

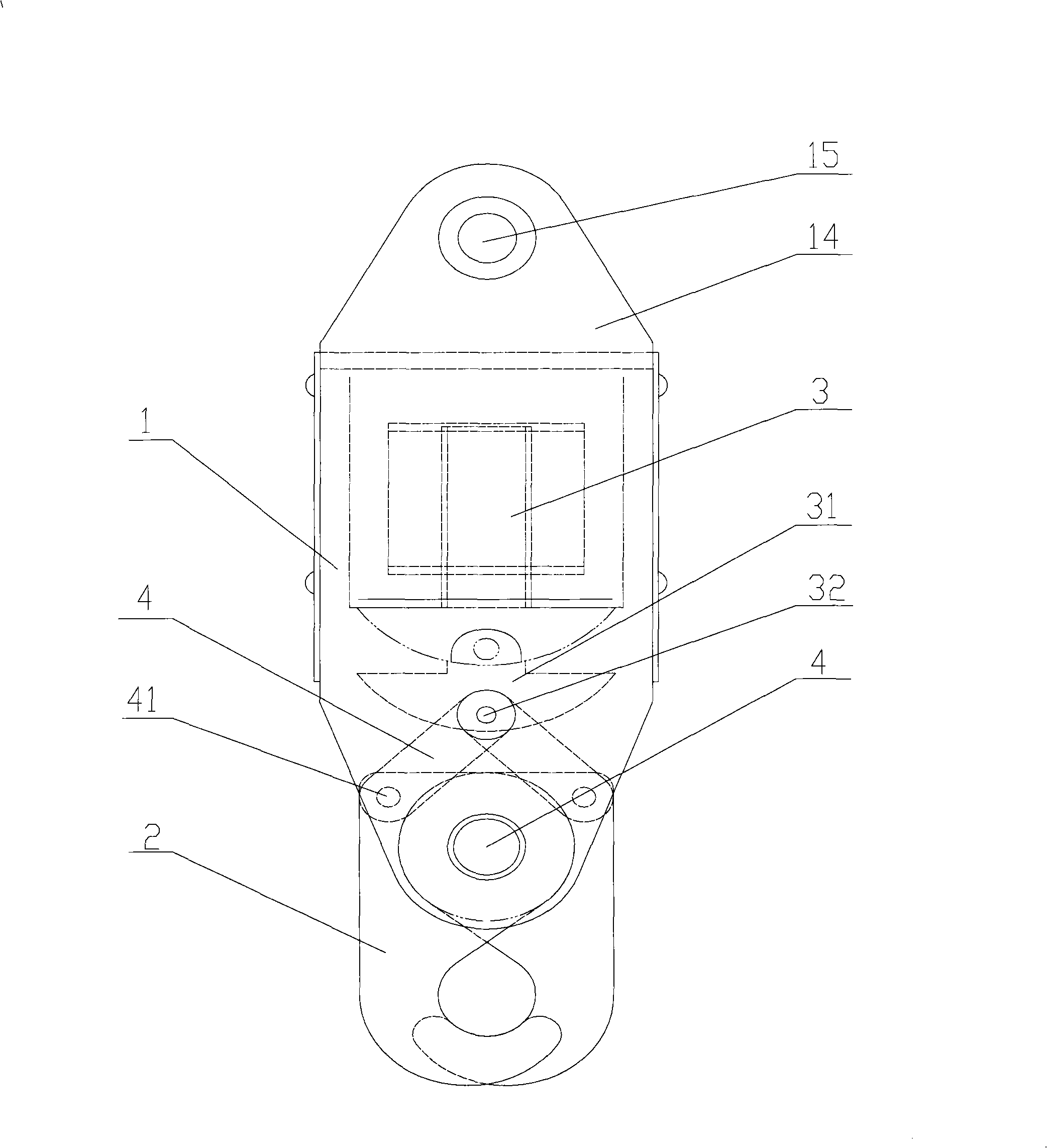

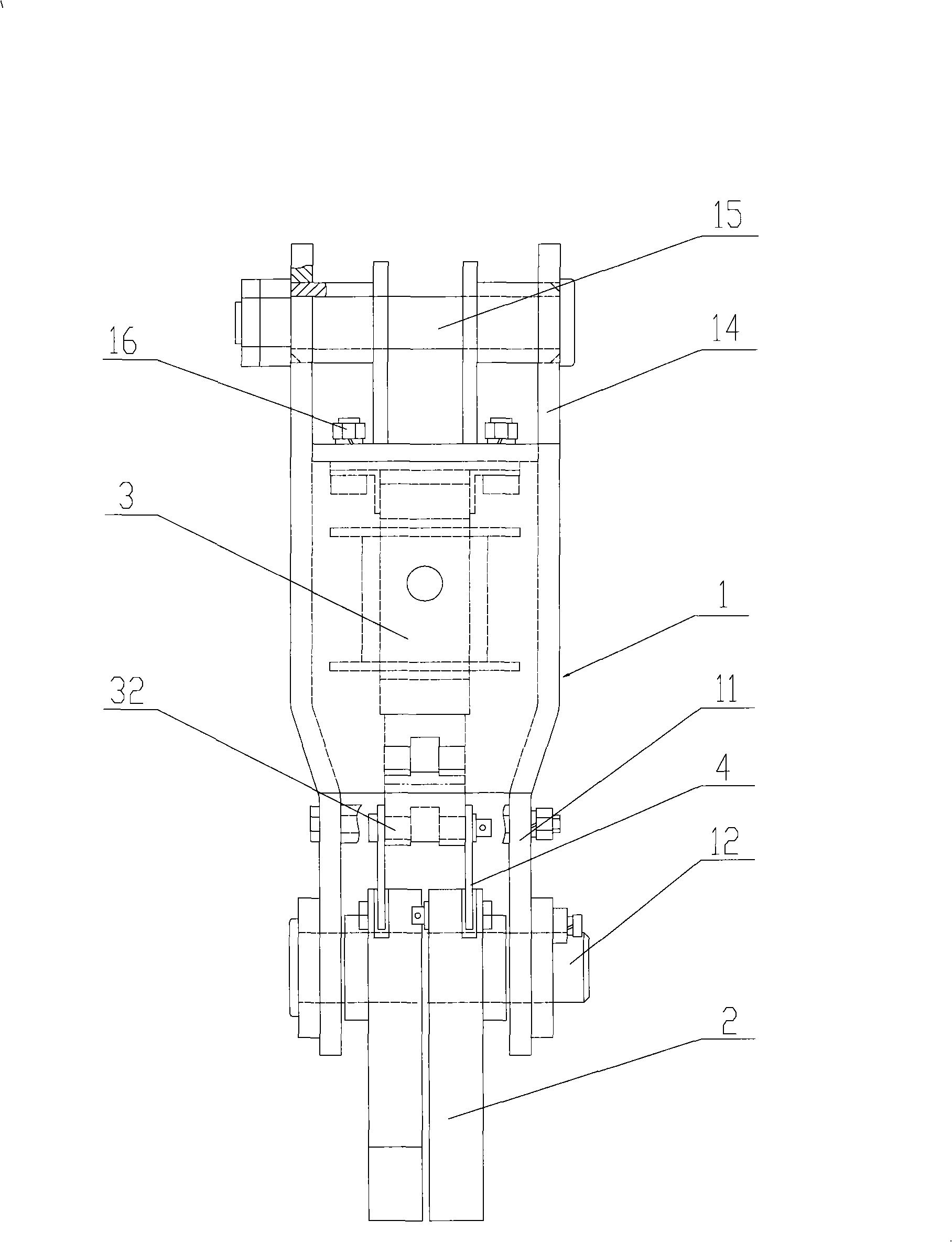

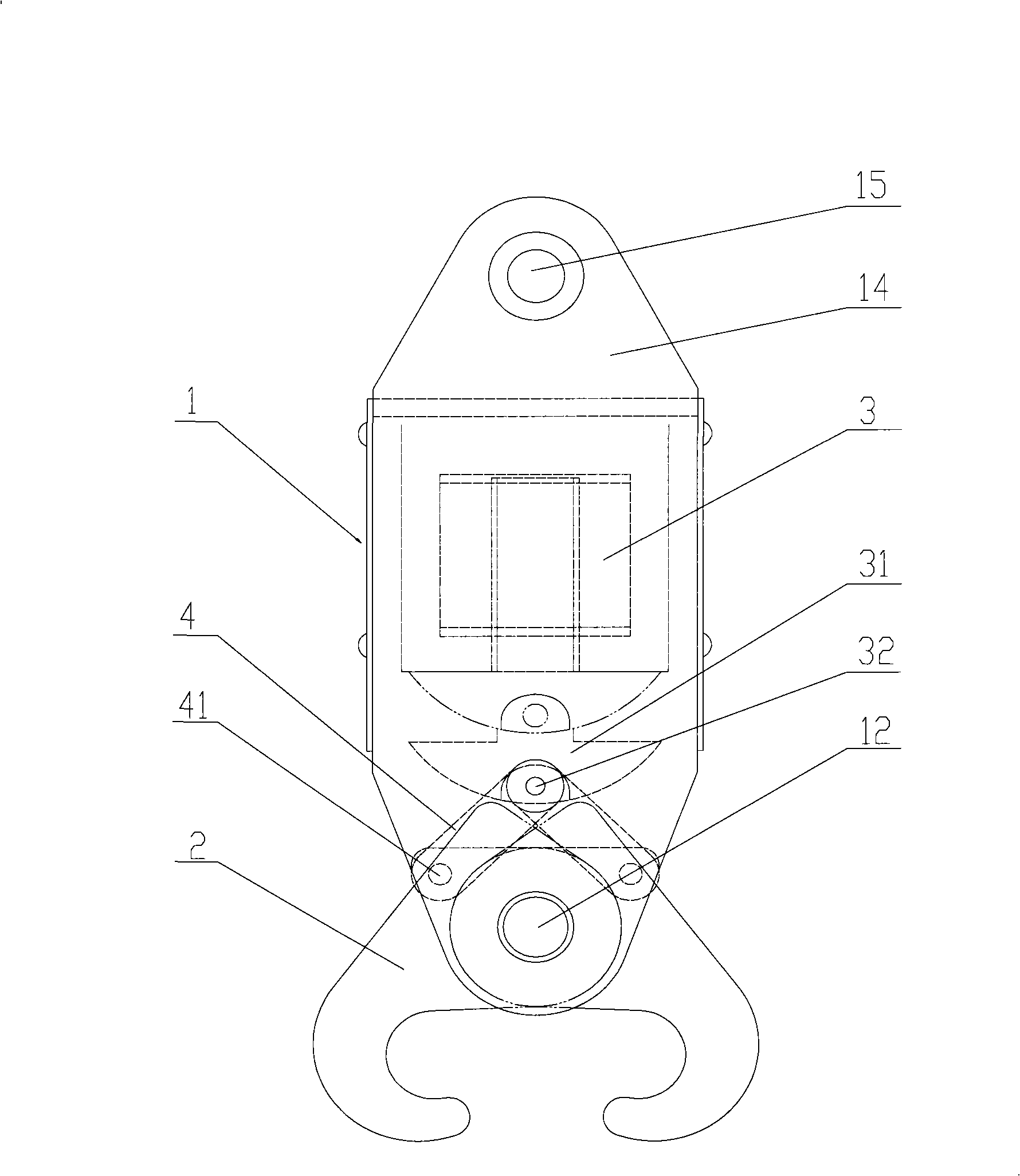

[0043] reference Figure 7 with Figure 8 , Figure 7 It is a front view of a specific embodiment of the hoisting machinery of the present invention; Figure 8 for Figure 7 Left view of the lifting machinery in. Since the main part of the hoisting machinery can use the existing technology, Figure 7 with Figure 8 The main structure of the hoisting machine is not shown, but only the structure of the part connected with the hook is shown.

[0044] Such as Figure 7 with Figure 8 As shown, the hoisting machine provided in this embodiment is specifically an electric hoist, of course, it can also be other electric hoisting machines such as a crane. The other structure of the electric hoist is not shown, and the electric hoist has the above-mentioned first electric hoist of the present invention. In the hook of an embodiment, the upper end of the hook is connected to the hook 7 of the electric hoist cable through the third pin 15. In this embodiment, the electric hoist further includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com