Heavy plate excellent in haz toughness and mother plate toughness

A thick steel plate, toughness technology, applied in the field of thick steel plate, can solve the problems of reduced hardenability, insufficient precipitation, not fine, etc., to achieve the effect of excellent toughness of the base metal

Inactive Publication Date: 2010-09-08

KOBE STEEL LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in Patent Document 3, the precipitation amount of TiN and BN is not sufficient, or is not fine, or due to insufficient Nb, the hardenability is lowered, and the ferrite becomes coarse, so there is room for further improvement of the HAZ toughness.

In addition, the toughness of the base metal is not considered

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

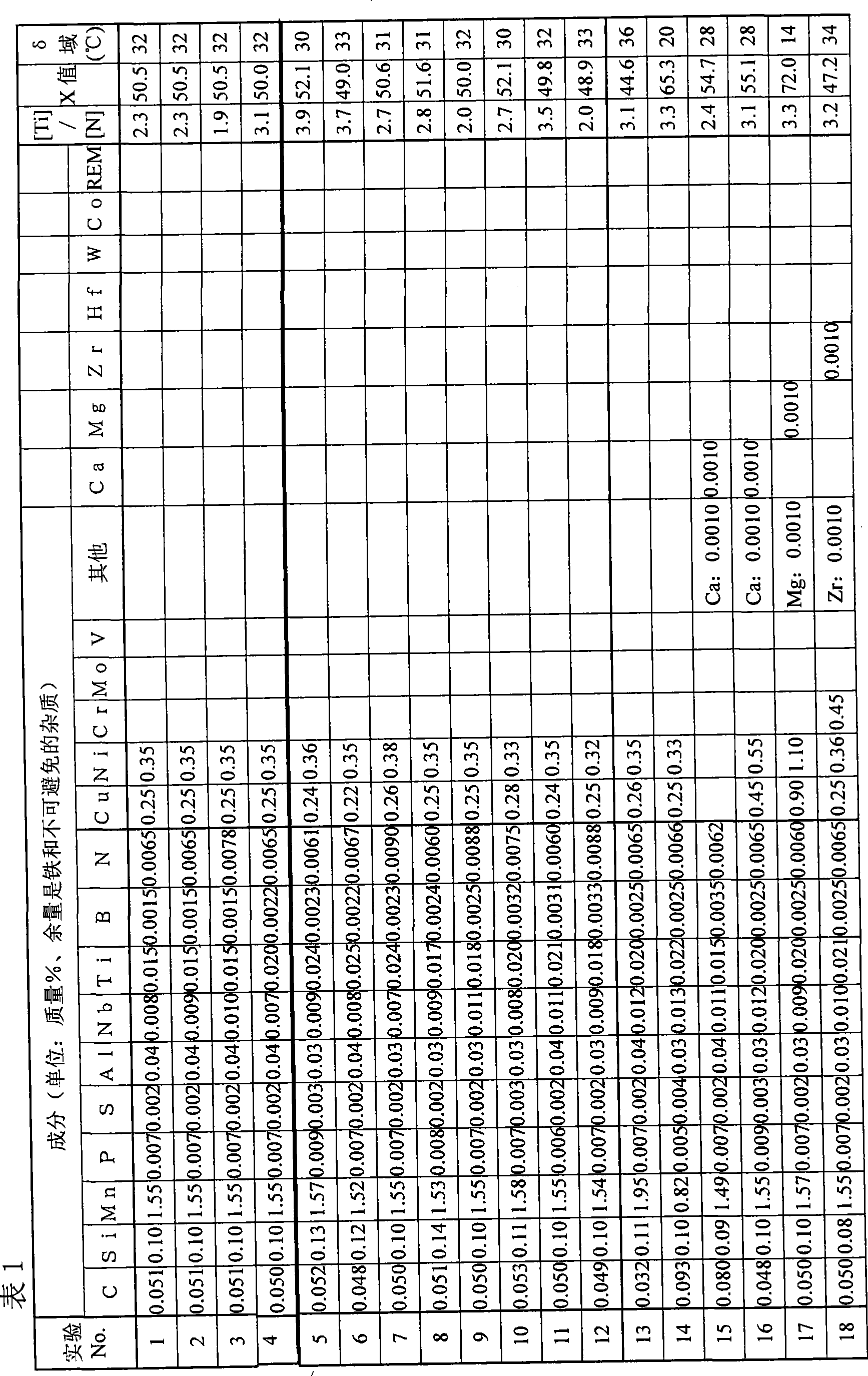

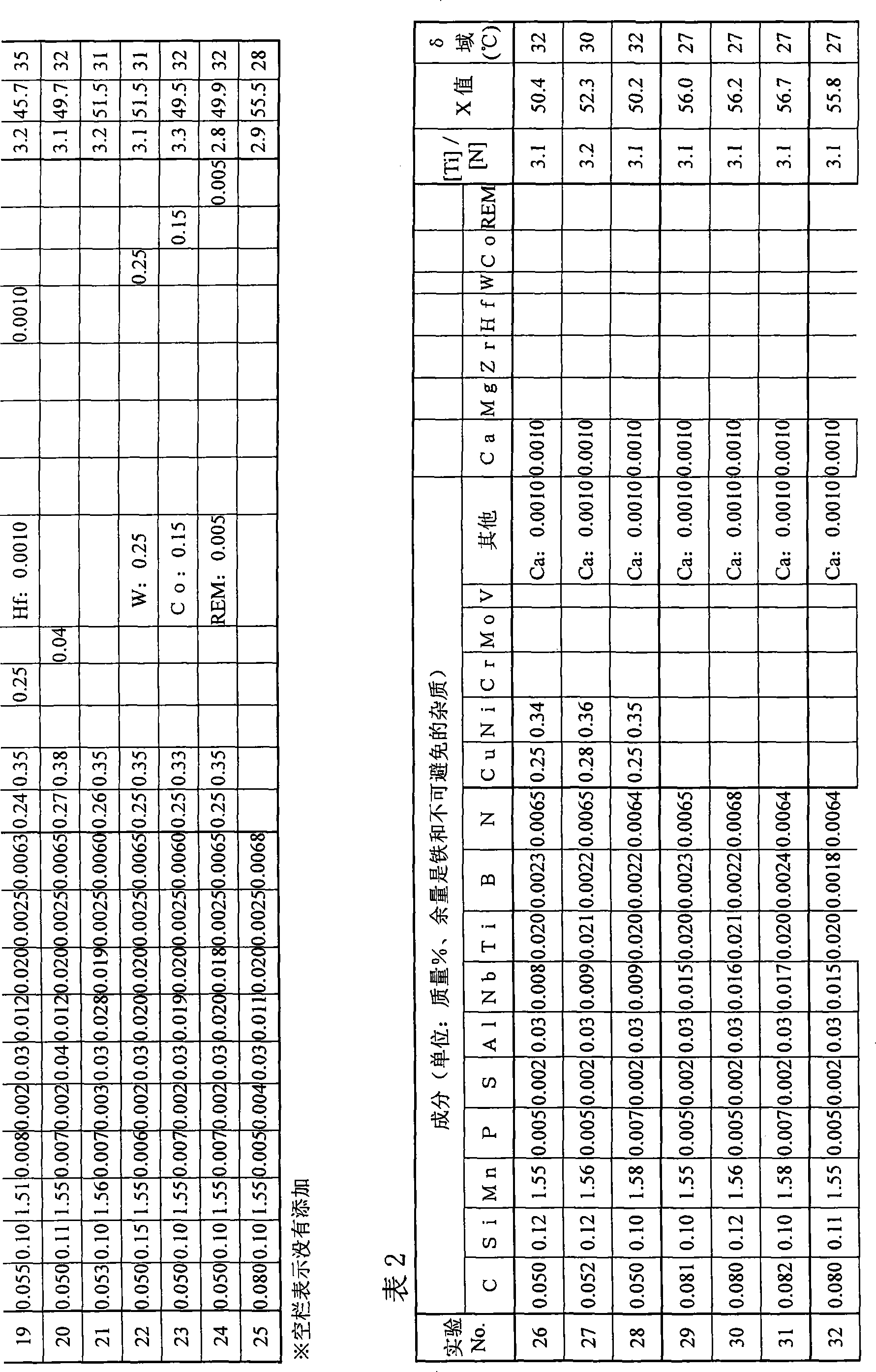

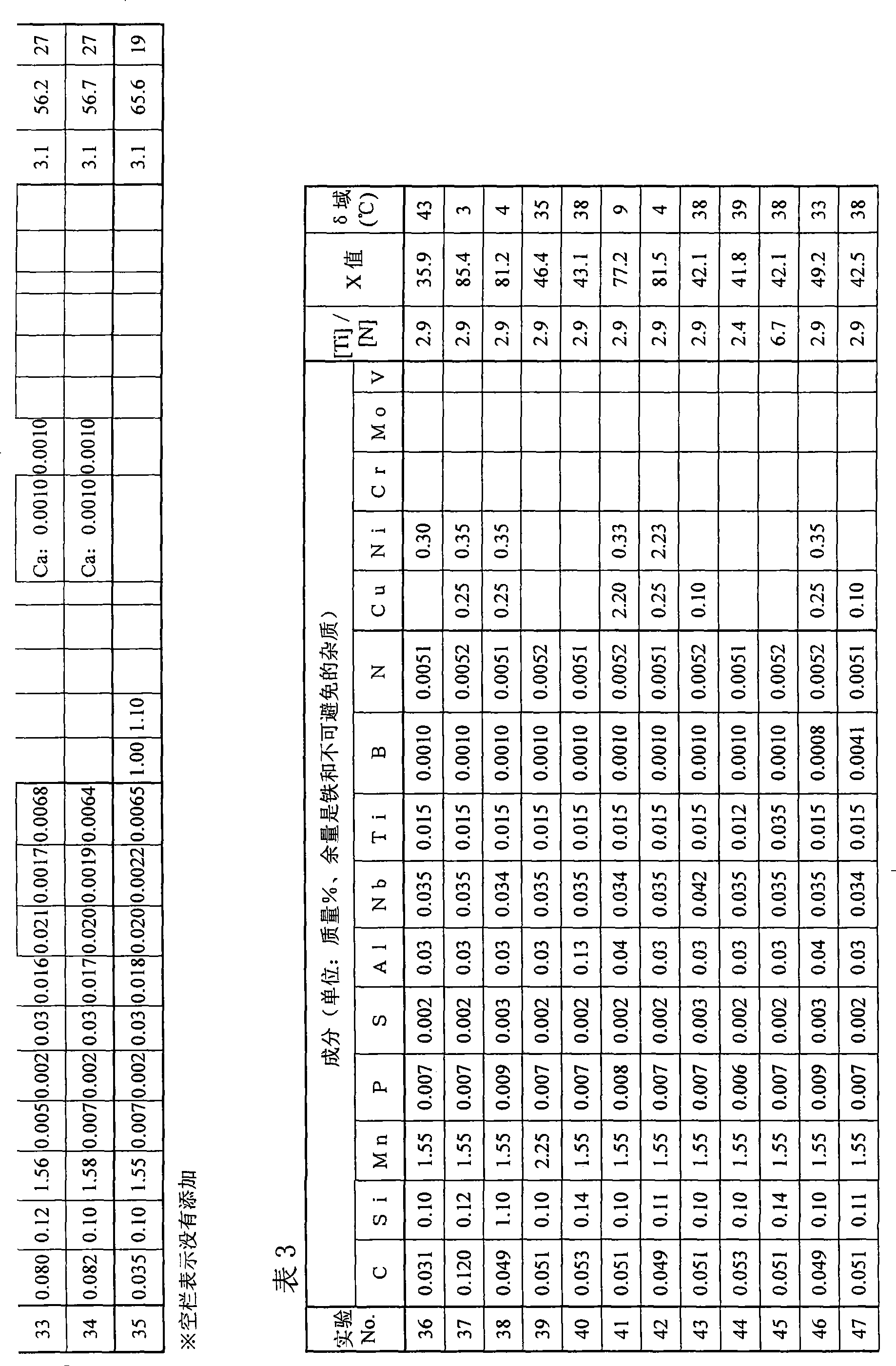

The invention provides a thick steel plate. The thick steel plate has a great HAZ toughness in the low heat energy input welding and super high heat energy input welding; and the parent material also has a great toughness. The thick steel plate contains C: 0.030-0.10%, Si: below 0.8-2.0%, P: below 0.03%, S: below 0.01%, Al: 0.01-0.10%, Nb: 0.005-0.035%, Ti: 0.015-0.03%, B: 0.0010-0.0035% and N: 0.0050-0.01%; the grain diameter of the old austenite crystal is below 120 um; the island-shaped martensite (MA) is below 3%; in addition, the invention satisfies the following formulas (1) (2): [Ti] / [N] is more than or equal to 1.5 and less than or equal to 4 (1); X value is more than or equal to 40 and less than or equal to 160 (2); the X value=500[C]+32[Si]+8[Mn]-9[Nb]+14[Cu]+17[Ni]-5[Cr]-25[Mo]-34[V].

Description

technical field The present invention relates to thick steel plates suitable for welded structures such as ships and marine structures. Preferably, it is a thick steel plate that has excellent toughness of the heat-affected zone (Heat Affected Zone: HAZ) after welding and excellent toughness of the base material even when welding is performed with a wide range of heat input from low heat input welding to ultra-high heat input welding. Background technique In recent years, for example, container ships and the like have been increased in size, and thick steel plates having a plate thickness of 60 mm or more have been used. In order to efficiently weld such a thick steel plate, it is required to have excellent HAZ toughness not only in low heat input welding but also in super high heat input welding with a heat input of 50KJ / mm or more. However, when performing ultra-high energy heat input welding, since the HAZ is heated to a high-temperature austenite region and then slowly...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/00

CPCC22C38/001C22C38/002C22C38/005C22C38/42C22C38/44C22C38/46C22C38/48C22C38/50C22C38/58

Inventor 高冈宏行冈崎喜臣

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com