Gas combustion range heat-releasing recovering device

A technology of heat recovery device and gas stove, which is applied to household heating, heating fuel, household stove/stove, etc., can solve the problems of energy waste, large radiation and convection loss, and high temperature in the environment, so as to shorten the heating time and improve the Furnace temperature, the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

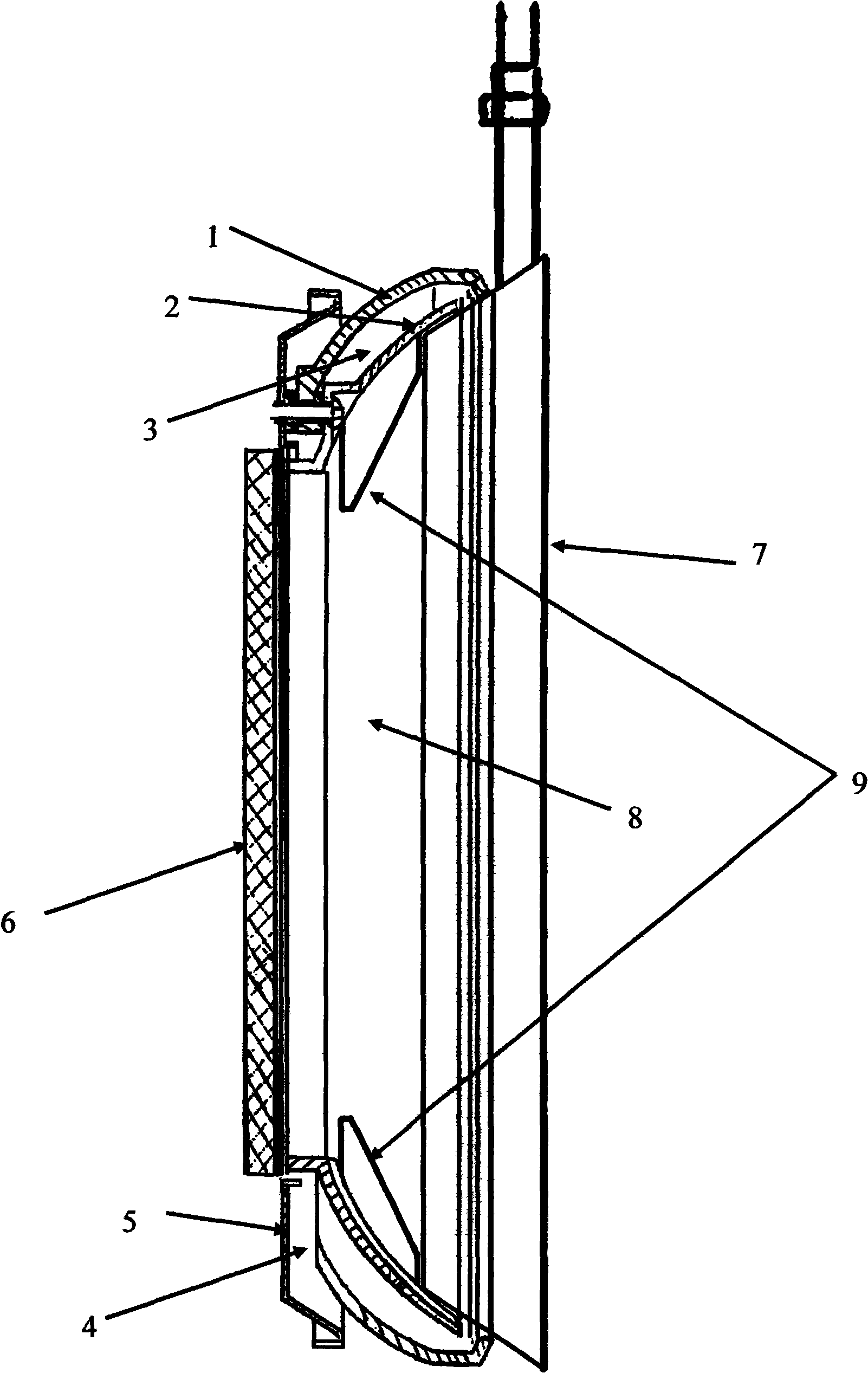

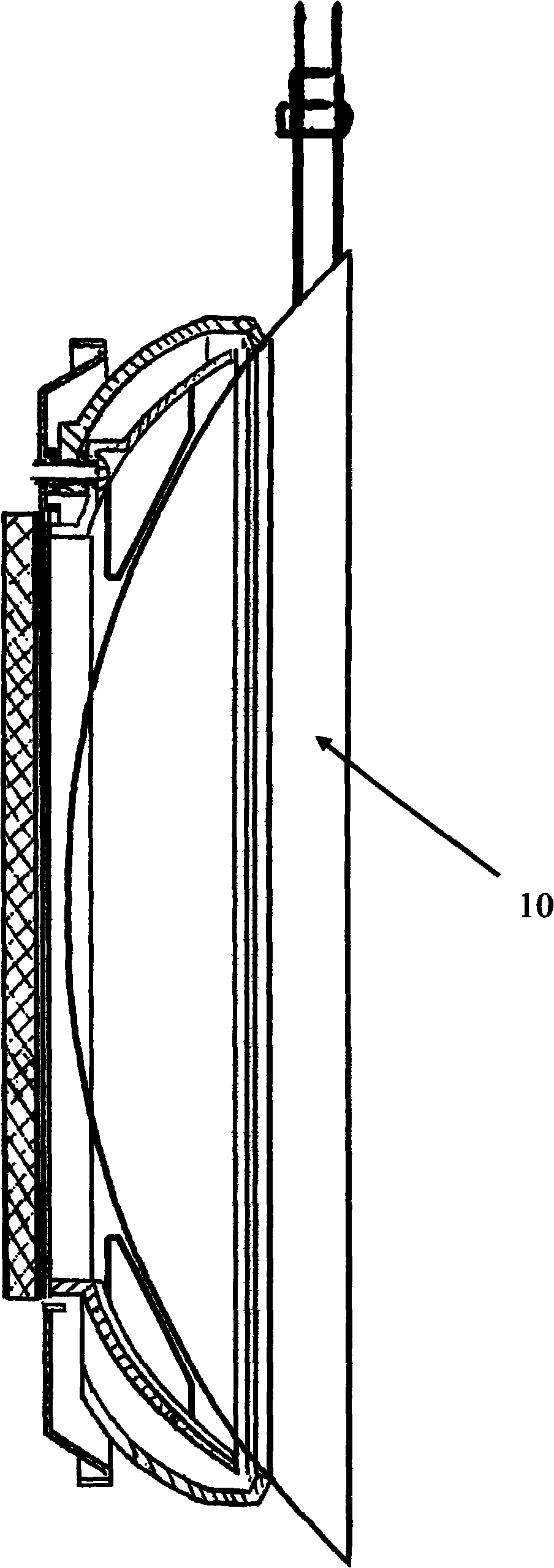

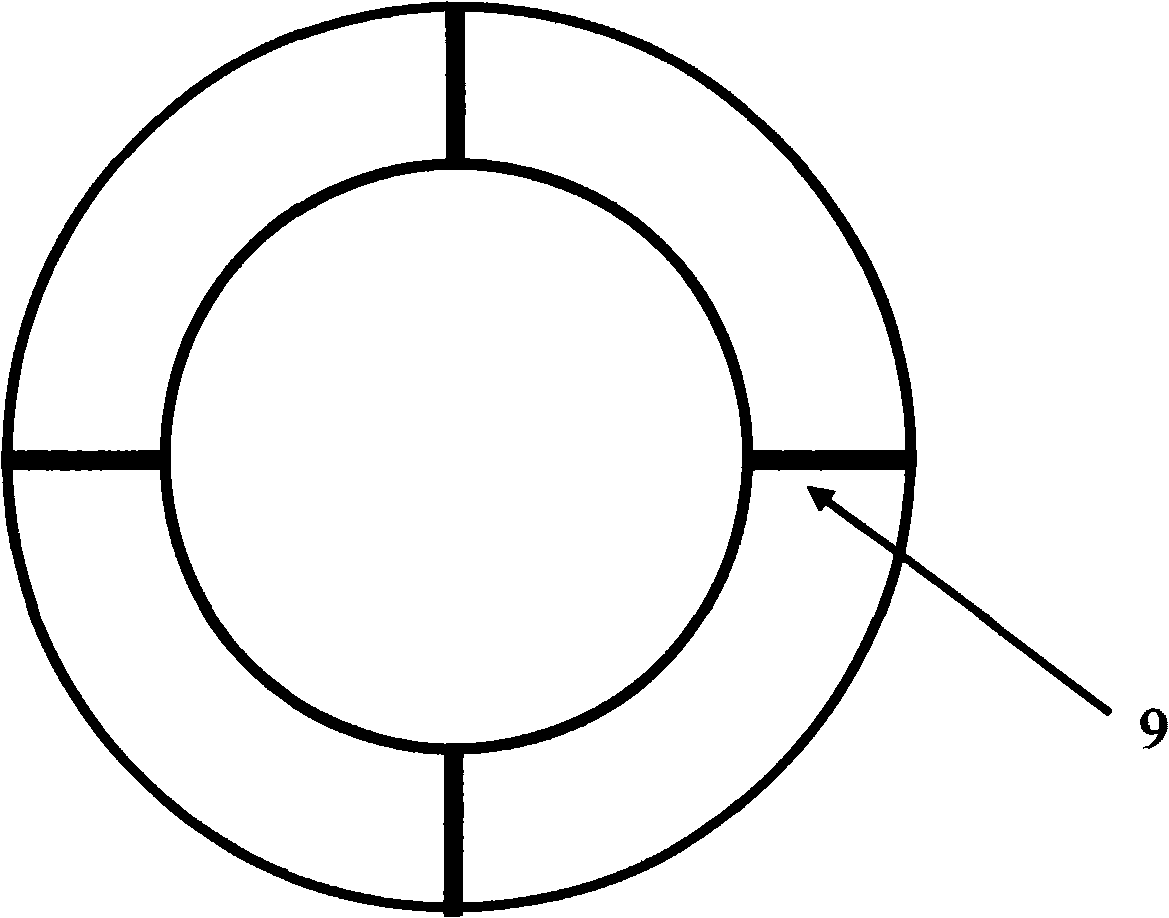

[0016] exist figure 1 and figure 2 Among them, the gas stove escape heat recovery device of the present invention can be made into different sizes and specifications and installed on various gas stoves of different sizes. In the figure, there is a gap of 5 to 8 mm between the heat collecting ring 2 and the heat reflecting cover body, and an exhaust gas deflector 5 is installed at the lower end of the heat collecting ring 2 and the heat reflecting cover body, and the exhaust gas deflecting plate 5 is annular, The middle part is hollowed out, and its size is consistent with the outer circle of the bottom of the heat collecting ring 2, and it is turned up at a certain interval along the outer circle of the heat reflection cover by 10 to 20 mm (the optimum is 15 mm). After the liquefied gas is mixed with air, it is ejected through the ceramic porous combustion sheet 6 and burns in the combustion chamber 8. Since the pan 7 (or round bottom pan 10) is closed and combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com