Thin-film transistor, manufacturing method for the same and liquid crystal display panel

A technology of thin film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as easy leakage currents, achieve enhanced control capabilities, reduce leakage currents, and improve leakage current characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

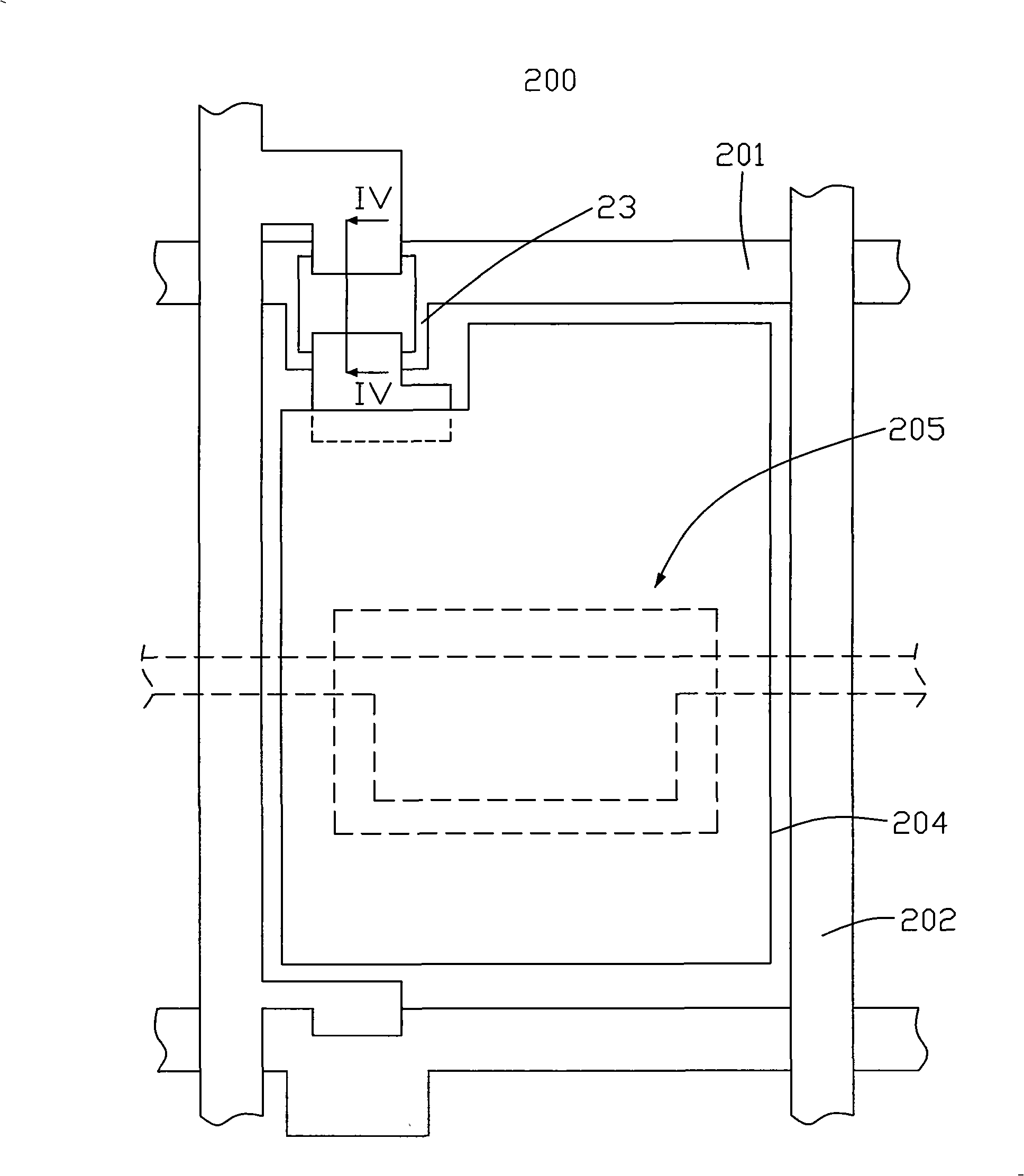

[0031] see image 3 , is a schematic diagram of the structure of the liquid crystal display panel of the present invention. The liquid crystal display panel 200 includes a plurality of rows of scanning lines 201 parallel to each other, a plurality of columns of data lines 202 parallel to each other and insulated from and intersecting with the scanning lines 201, and a plurality of thin films adjacent to the intersections of the scanning lines 201 and the data lines 202 The transistor 23 , a plurality of pixel electrodes 204 and a common electrode 205 opposite to the plurality of pixel electrodes 204 . The pixel electrodes 204 are arranged in a matrix in a region defined by the rows of parallel scanning lines 201 and the columns of parallel scanning lines 201 . The gate of the TFT 23 is correspondingly connected to a scan line 201 , its source is correspondingly connected to a data line 202 , and its drain is correspondingly connected to a pixel electrode 204 .

[0032] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com