Leakage current characteristic improvement method of dry type lamination ceramic capacitor

A technology of laminated ceramics and leakage current, which is applied in the direction of fixed capacitor electrodes and parts of fixed capacitors, etc., can solve the problems that the leakage current characteristics are difficult to improve, and achieve the goals of improving leakage current characteristics, strong stability, and improving evaporation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

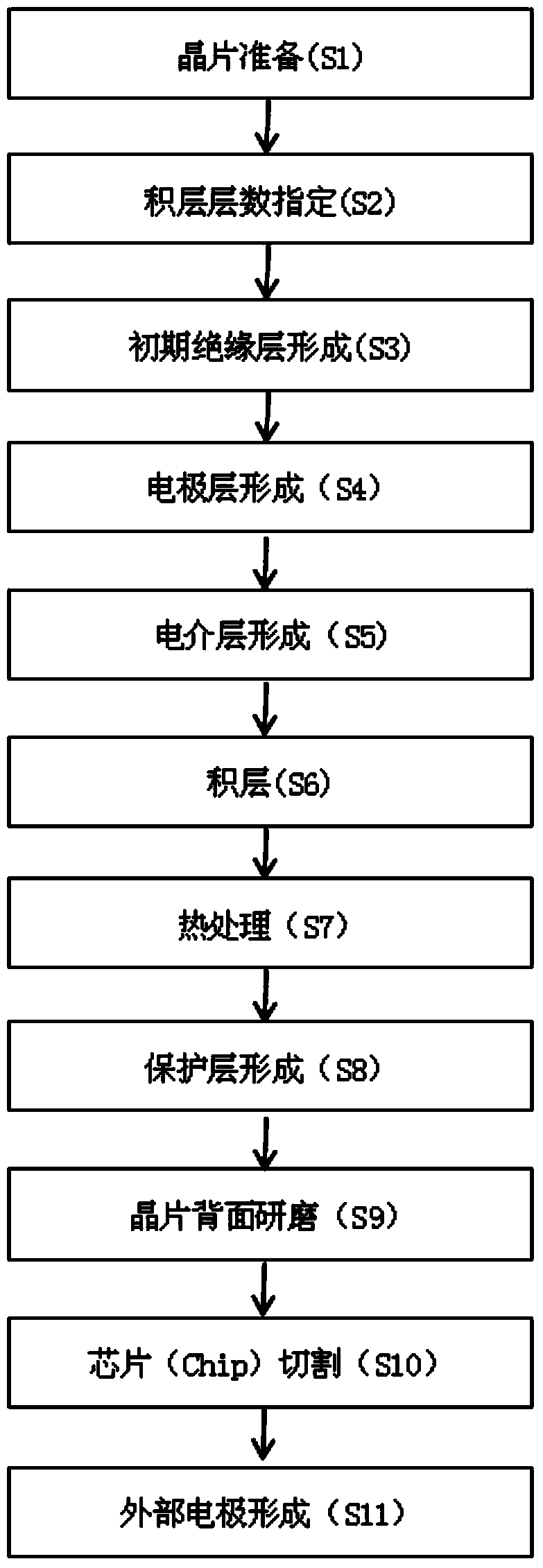

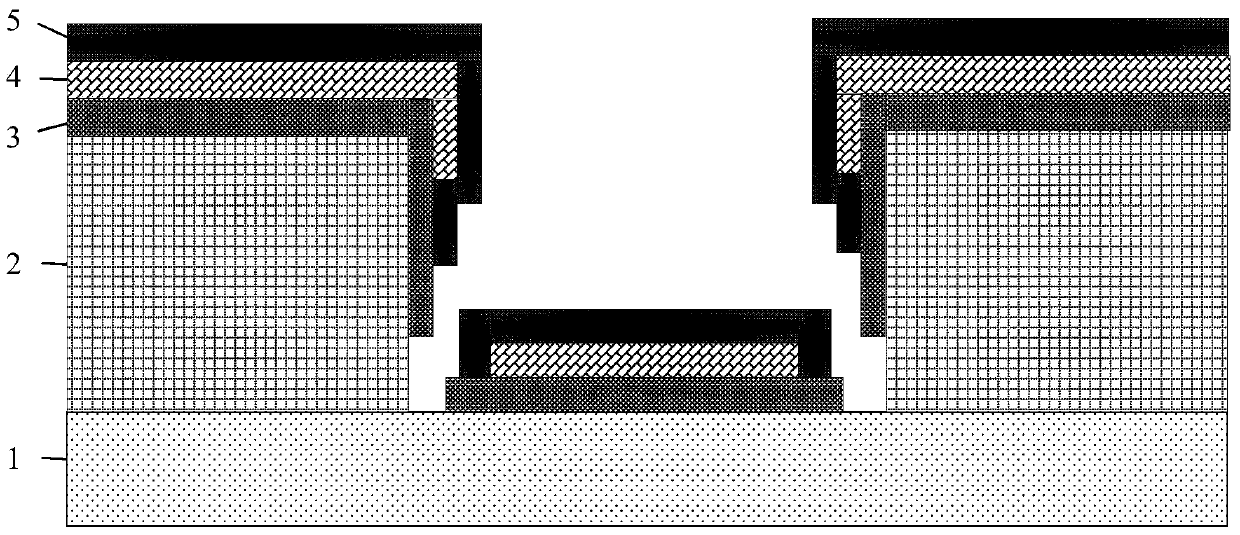

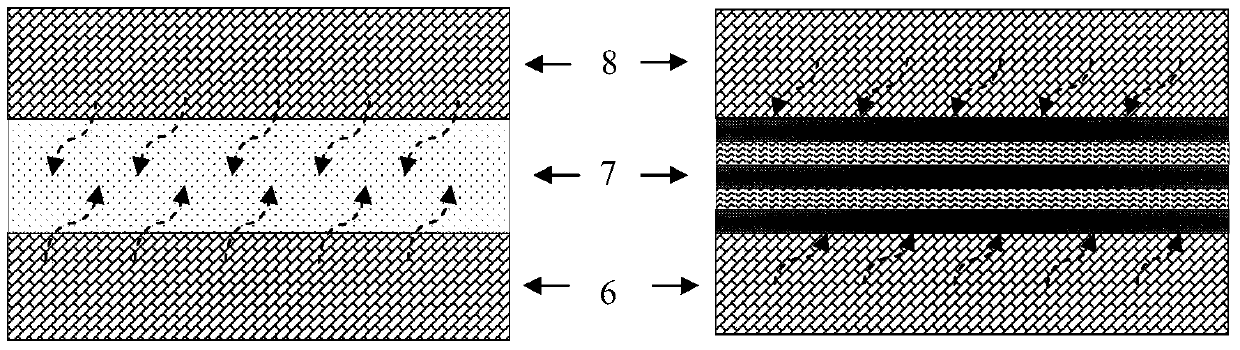

[0036] Such as Figure 1-3 As shown, the method for improving the leakage current characteristics of dry-type laminated ceramic capacitors includes the following steps:

[0037] S1: wafer preparation stage;

[0038] S2: Designate the stage of the number of stacked layers of the electrode layer and the dielectric layer on the wafer;

[0039] S3: the stage of forming an initial insulating layer on the wafer;

[0040] S4: a stage of forming an electrode layer on the initial insulating layer;

[0041] S5: a stage of forming a dielectric layer on the electrode layer;

[0042] S6: The stage in which electrode layers and dielectric layers are repeatedly laminated;

[0043] S7: After lamination, the stage of heat treatment of electrode layer and dielectric layer;

[0044] S8: the stage of forming a protective layer after heat treatment;

[0045] S9: After the protective layer is formed, the wafer back grinding stage;

[0046] S10: Cutting stage in chip form after wafer back gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com