Well having inductively coupled power and signal transmission

A signal unit and wellbore technology, applied in electromechanical devices, drilling equipment, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

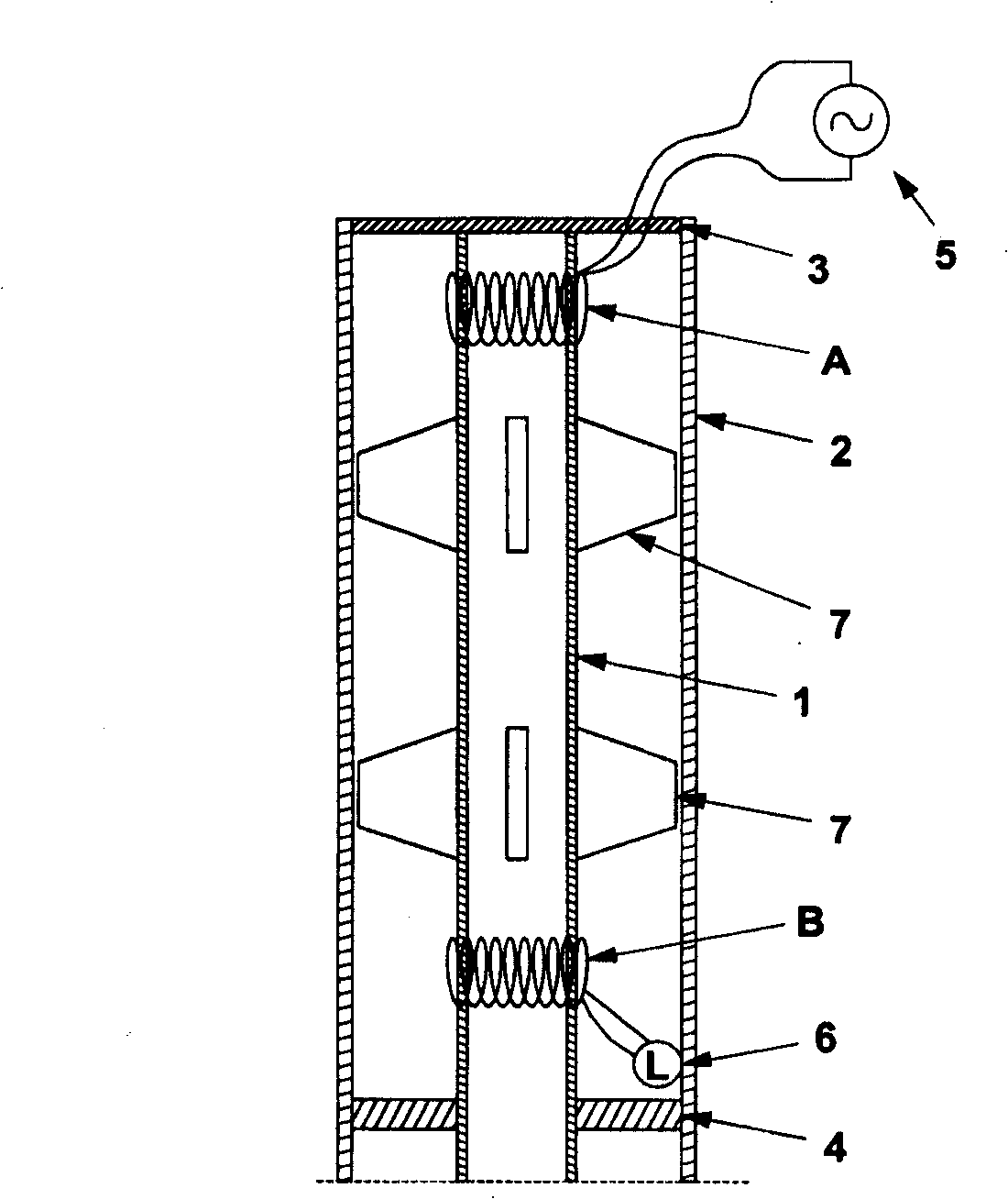

[0028] A 2000m long well transmits 1kW from top to bottom. Experiments have shown that 50% efficiency is practical. Therefore, 2kW must be applied to the main coil. A convenient main coil is about 8m long and consists of 80 identical coils arranged side by side, connected in parallel, each with about 250 0.2mm 2 coils of copper wire. By applying approximately 9.1A of 220V, 50Hz AC to the main coil, 25W will be applied to each of the 80 coils that make up the main coil, and 0.1A will be applied to each of the 80 coils that make up the main coil. The closed circuit of the well, including the production tubing and casing short-circuited at the top and bottom of the well, can be seen as a coil, and therefore if losses are ignored, the voltage and current of the closed circuit are 80 x 220 / 250 = 70.4V, respectively and 9.1 x 250 / 80 = 28.43A. However, losses do exist due to resistive losses in the production tubing and casing, typically around 2 ohms in actual wells. If you use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com