Detachable tooth shape, different diameter tooth shape pile die

A tooth shape and mold technology, which is applied in the field of molds for the production of prestressed piles, can solve the problems of long production time, complicated process, and high processing costs.

Inactive Publication Date: 2008-10-22

郭兆泉

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the continuous innovation of technology, the forms of prestressed pipe piles, in addition to smooth pipe piles, have successively appeared bamboo piles, tooth surface drainage pipe piles with sand lining, etc. These new piles are characterized by remarkable bearing capacity. Improvement, indirect energy saving, consumption reduction, and emission reduction effects are very objective, and should be vigorously promoted, but this kind of mold processing cost is very high, for example: a mold factory processes a bamboo pile mold with a length of 12.4 meters and a diameter of less than 400mm It needs more than 90,000 yuan and the production time is long and the process is complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Login to View More

Abstract

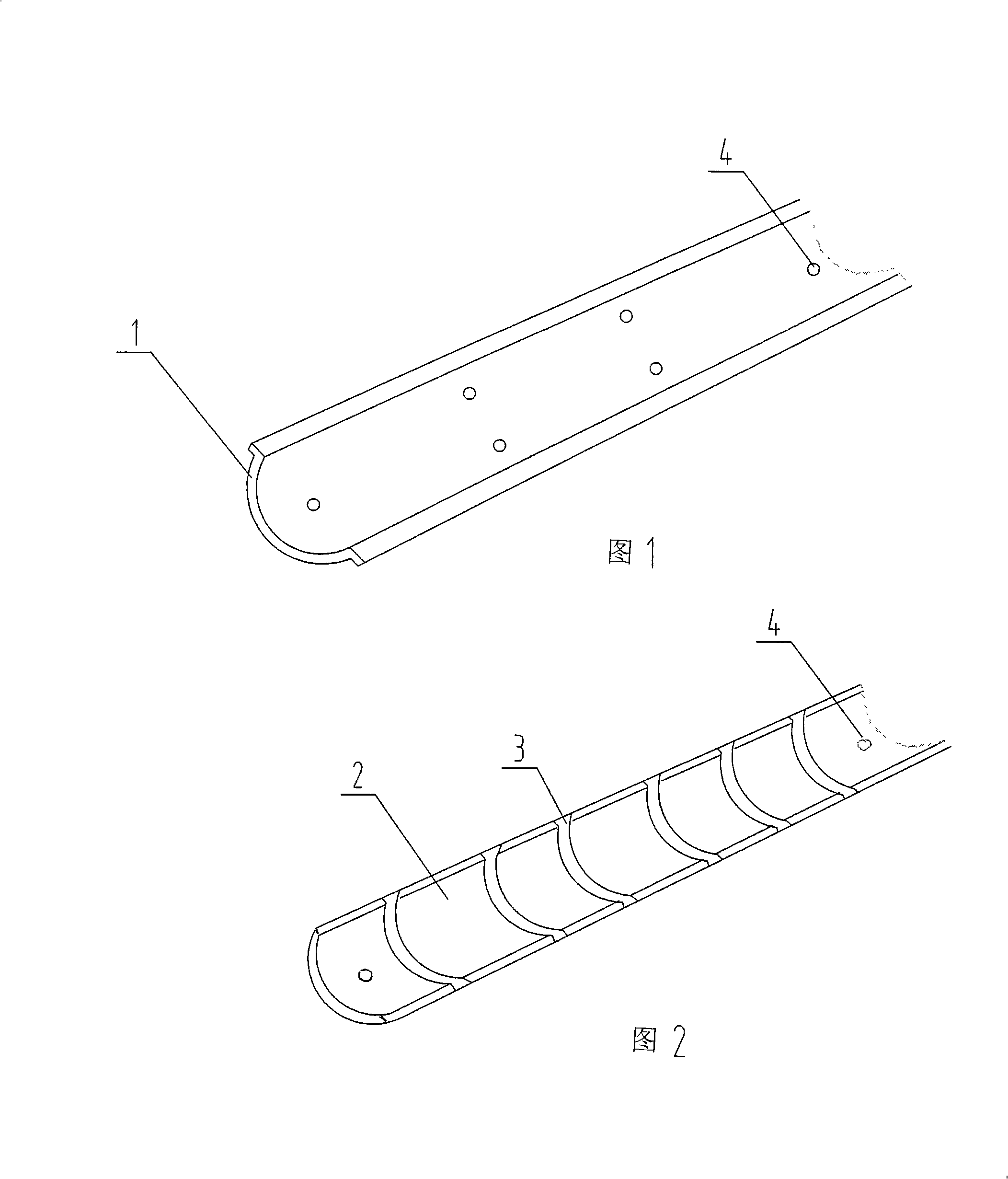

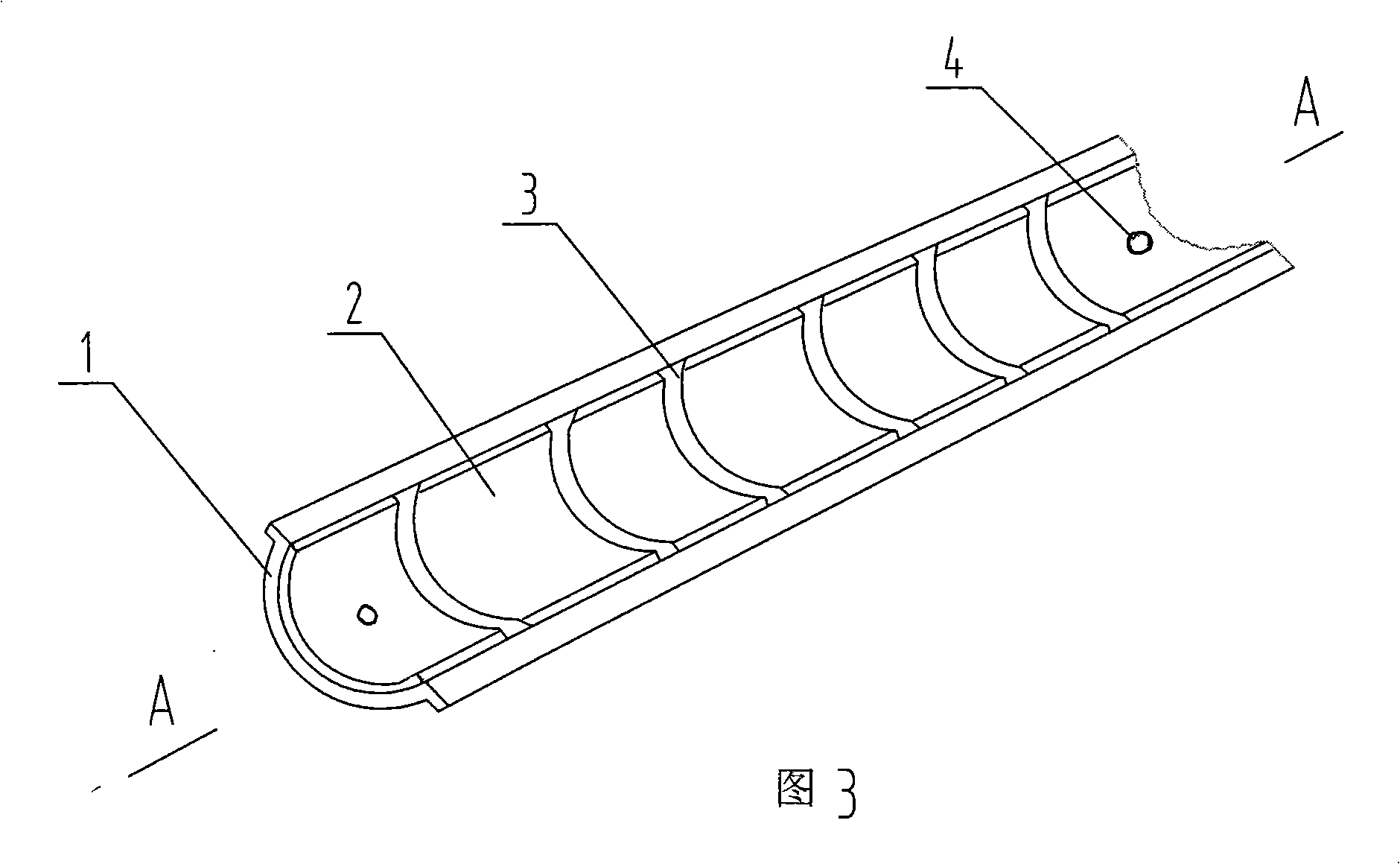

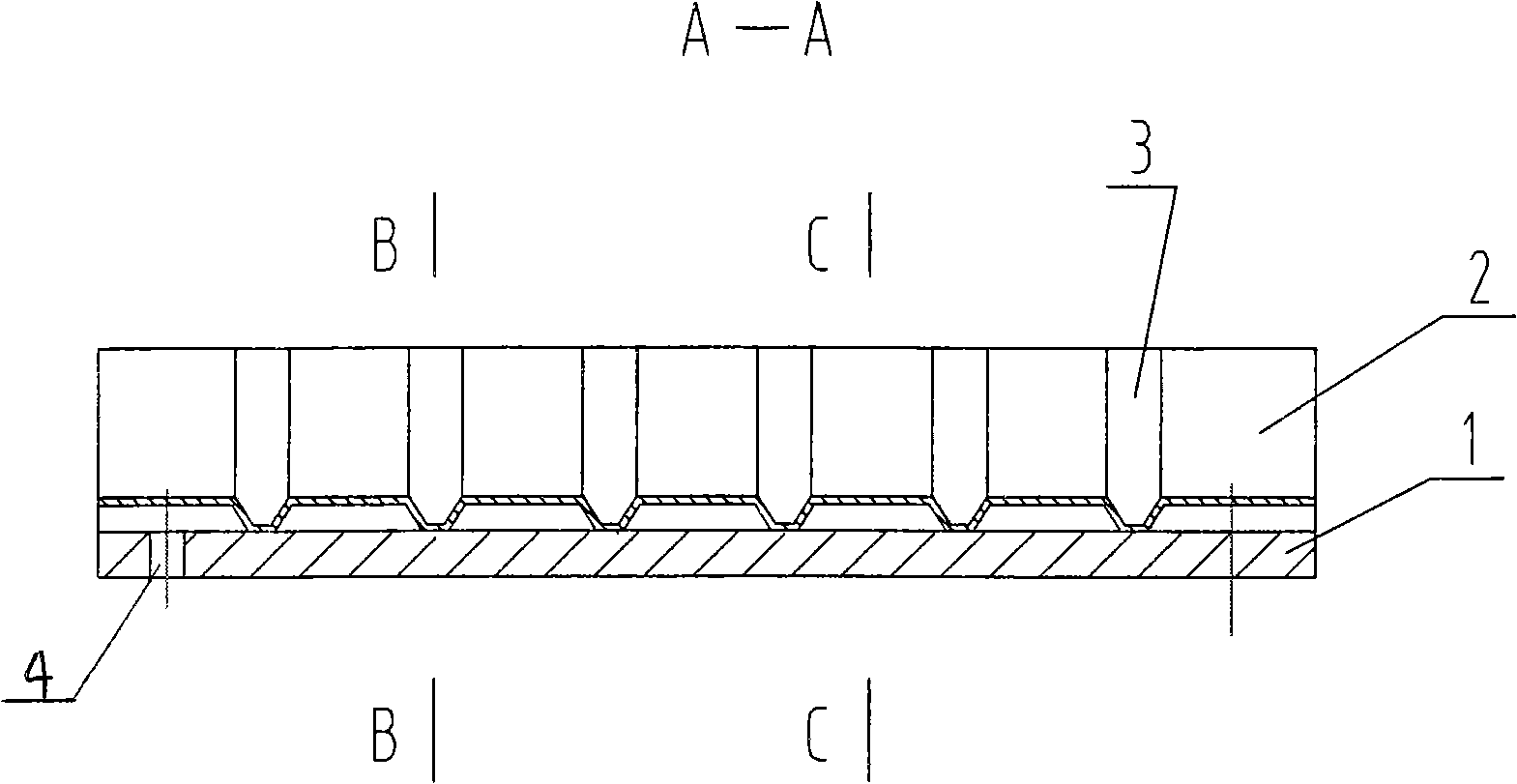

A die for a dismountable tooth-shaped pile and a different diameter tooth-shaped pile is provided with two strip-typed semi-circular smooth pipe dies that can be connected together by a fastener. The pile die of the invention is characterized in that each smooth pile die is provided with a mould core that is pressed and manufactured by a steel plate and is matched with the shape of an inner wall of the die; the inner wall of the mould core is provided with annular concave teeth at intervals of 150 to 750mm; one mould can be multi-functional without being processed into a novel die; therefore, the expansive cost for manufacturing the dies of the tooth-shaped pile and the different diameter tooth-shaped pile is reduced to the lowest; simultaneously a large amount of steel material are saved for the country; besides, huge working load during the transportation is reduced and the transportation cost is reduced, thus being beneficial to popularizing the tooth-shaped pile and the different diameter tooth-shaped pile in the whole country.

Description

Detachable tooth-shaped and different-diameter tooth-shaped pile molds technical field The invention relates to a mold for producing prestressed piles, in particular to a detachable mould for tooth-shaped and different-diameter tooth-shaped piles. Background technique With the continuous innovation of technology, the forms of prestressed pipe piles, in addition to smooth pipe piles, have successively appeared bamboo piles, tooth surface drainage pipe piles with sand lining, etc. These new piles are characterized by remarkable bearing capacity. Improvement, indirect energy saving, consumption reduction, and emission reduction effects are very objective, and should be vigorously promoted, but this kind of mold processing cost is very high, for example: a mold factory processes a bamboo pile mold with a length of 12.4 meters and a diameter of less than 400mm It needs more than 90,000 yuan and the production time is long and the process is complicated. Contents of the invent...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B28B21/82

Inventor 郭兆泉

Owner 郭兆泉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com