Method for applying pretreatment of amylase to swine waste marsh gas fermentation

A technology of biogas fermentation and amylase, which is applied in application, biological sludge treatment, biomass pretreatment, etc., can solve the problems of shortening the start-up time of fermentation, and achieve the goal of increasing biogas production rate, shortening fermentation time, and increasing biogas production Effect

Inactive Publication Date: 2008-10-22

KUNMING UNIV OF SCI & TECH

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, none of these studies and experiments involve the treatment of pig manure with hydrolytic enzymes before biogas fermentation to degrade

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

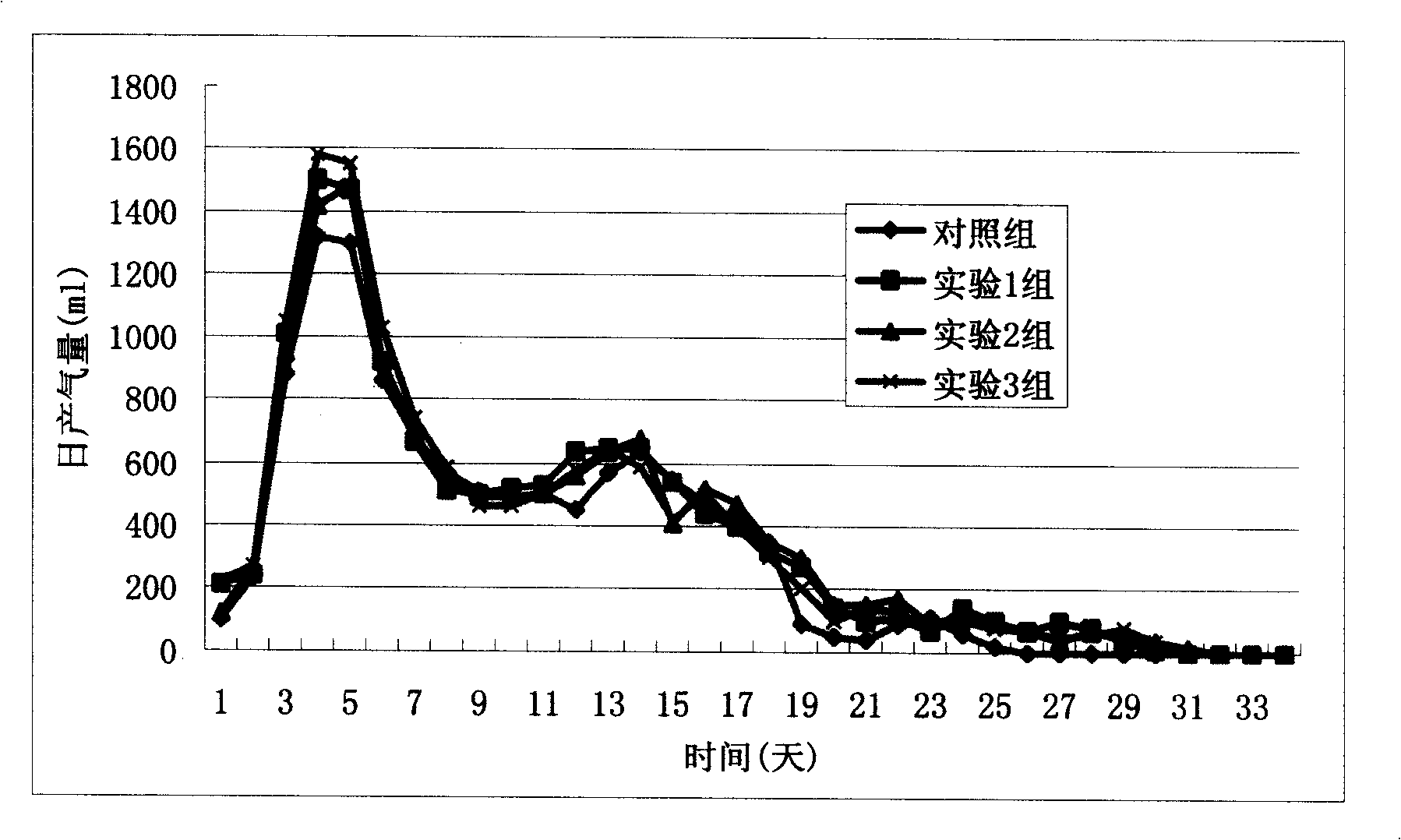

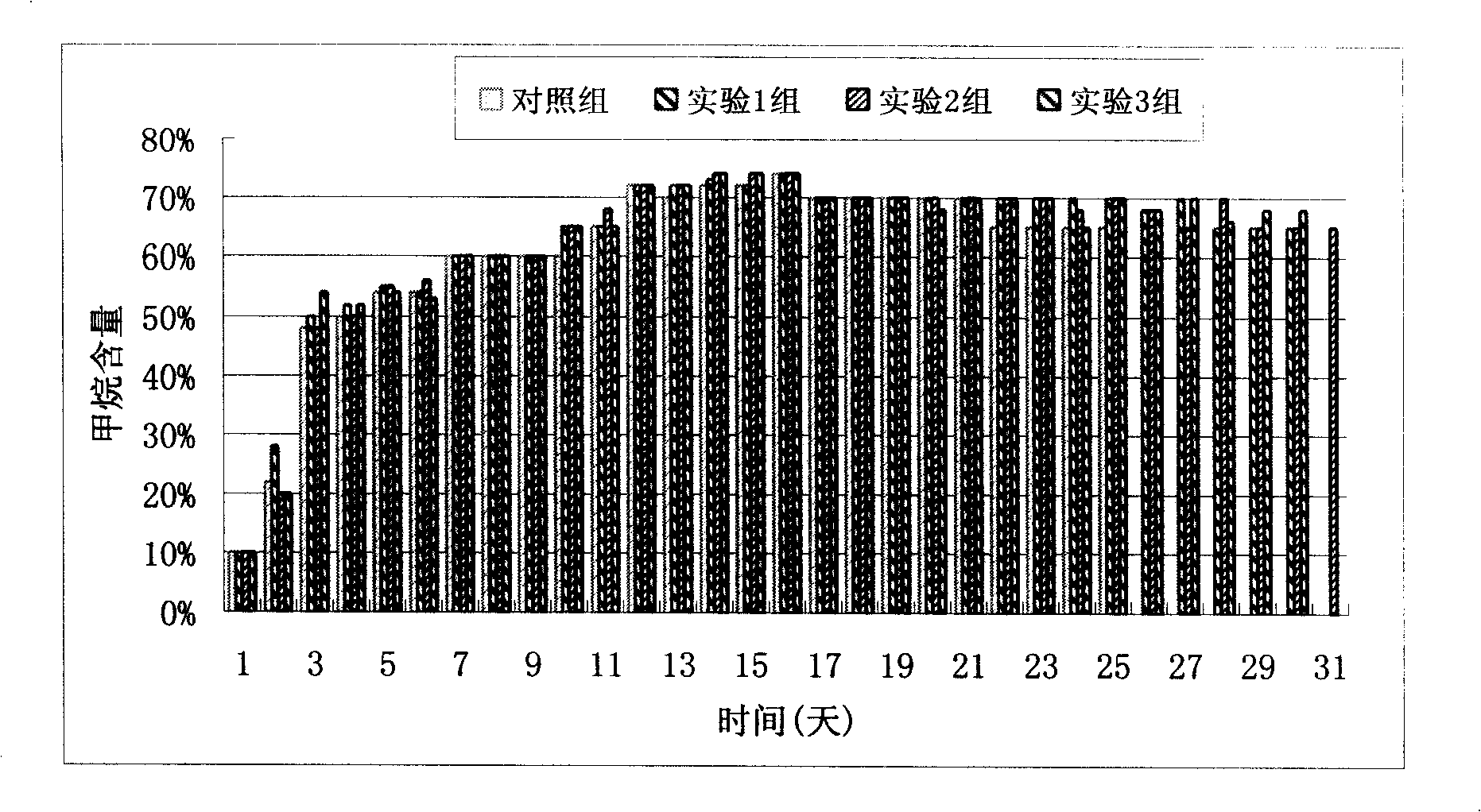

The invention relates to a method for producing methane by utilizing enzyme to process organisms. The method includes the steps that pig manure is weighted and fermentation liquid is prepared according to the concentration of the total content of solids (TS) of the pig manure; Alpha-amylase or Gamma-amylase is added to the prepared fermentation liquid for processing the liquid; the processed fermentation liquid is mixed with inoculum for the fermentation of the methane. The method adopts amylase for the pre-processing of the fermentation of the pig manure and the result shows that the degradation rate of the TS and the VS of the pig manure, the methane yield factor in the maximum volume, the accumulated methane yield and the potential of the raw materials for methane yield have remarkable growth compared with a comparison group, wherein, the processing effect of disaccharidase is better than that of the Alpha-amylase while the processing effect of the Alpha-amylase is better than that of the Gamma-amylase.

Description

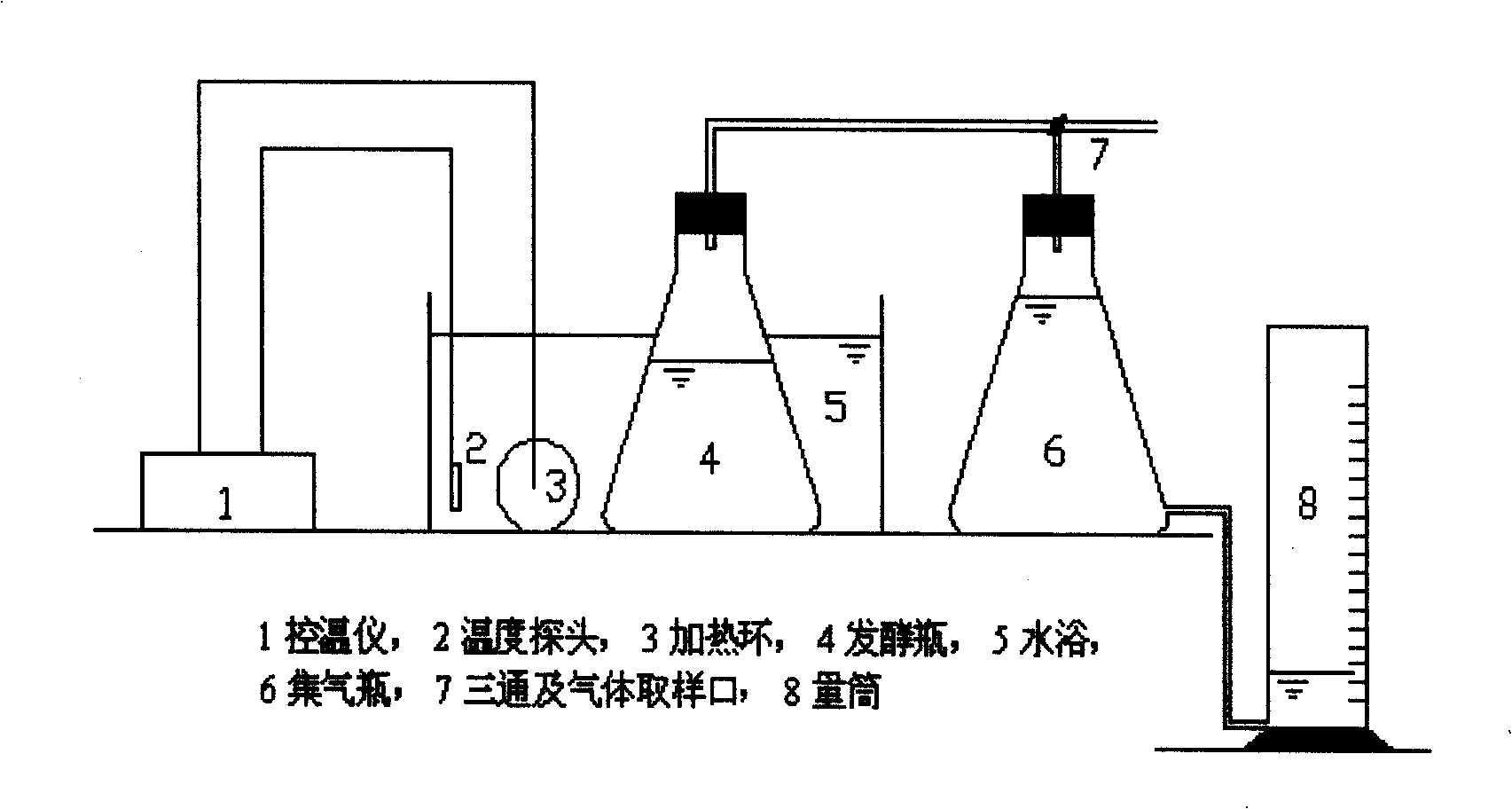

technical field [0001] The invention belongs to a biogas fermentation method which uses enzymes to process organic matter in an anaerobic environment to generate biogas. Background technique [0002] Biogas fermentation involves the synergistic action of a variety of microorganisms to jointly degrade complex organic matter, which can be divided into three stages: hydrolysis, hydrogen production, acid production, and methane production (Zhang Wudi, Liu Shiqing, Multifunctionality of anaerobic digestion process[J], Tianjin Microbiology, 1995(3):24-26). When the raw material used in biogas fermentation is macromolecular complex organic matter, the hydrolysis stage will be the main limiting stage of the whole process (Zhang Jishi, Sun Kewei, Xu Jing, Research on the influence of lysis treatment of municipal organic solid waste and its heap anaerobic digestion[ J], Ecological Environment, 2006, 15(4): 862-865). Therefore, before biogas fermentation, pretreatment of macromolecul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F11/04C05F3/00C12M1/107

CPCY02E50/343C12M21/04C12M45/06Y02E50/30Y02W30/40

Inventor 李建昌孙可伟吴勇生

Owner KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com