Laneway fluid pipe trailer fixing device

A fixed device and liquid pipe technology, applied in mining devices, mining equipment, earthwork drilling and other directions, can solve problems such as affecting the speed of mechanized mining, affecting other operations and construction, occupying roadway space, etc., to achieve automatic transportation, simple structure, Ease of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

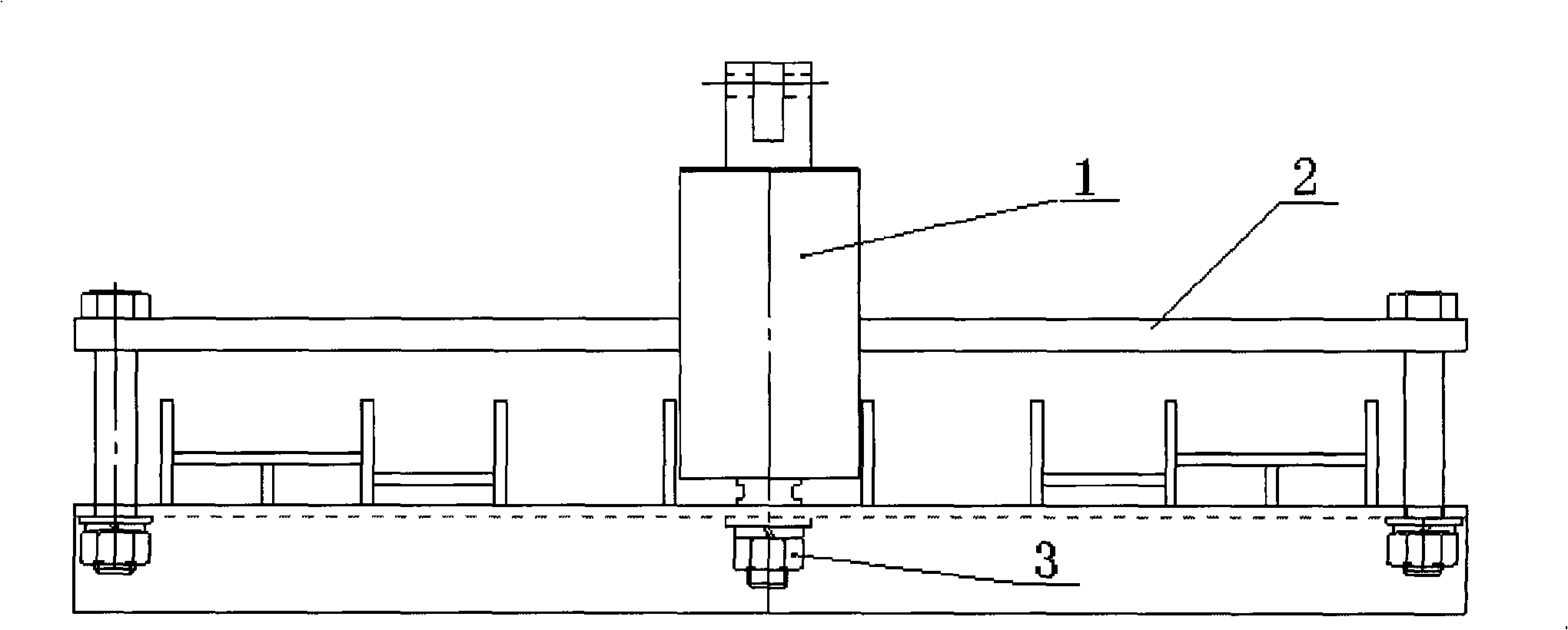

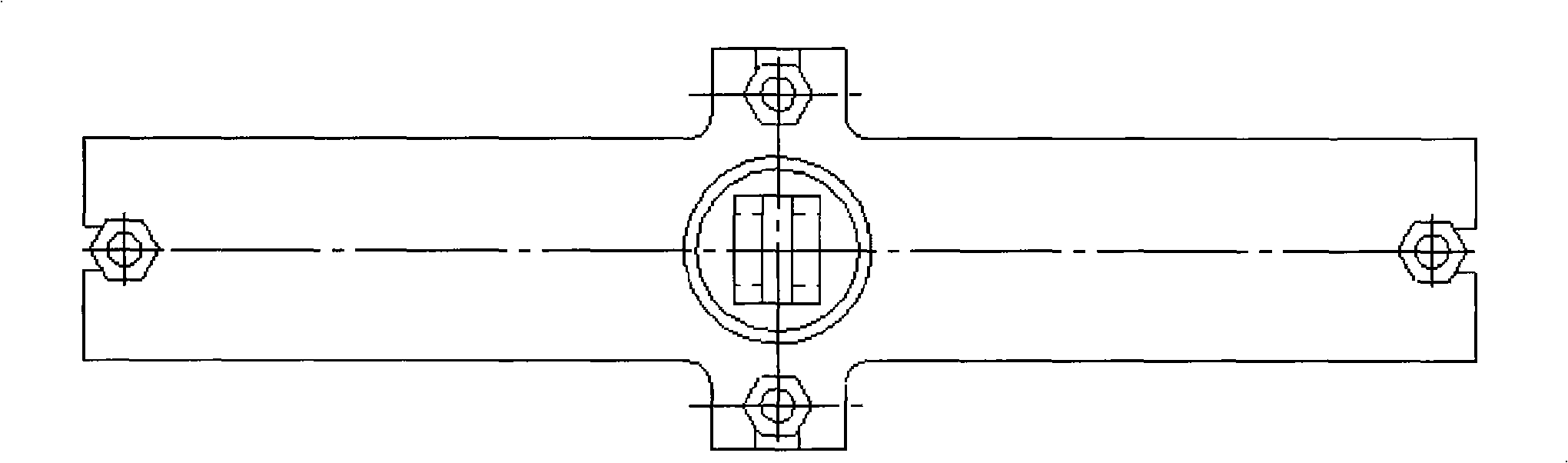

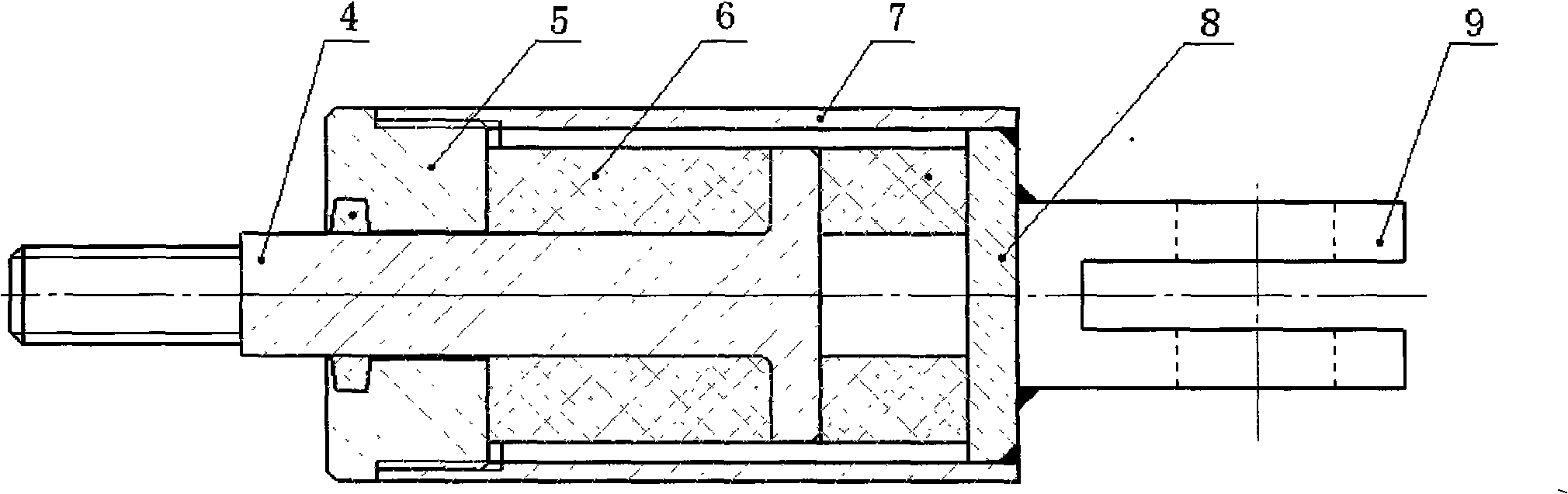

[0019] Specific embodiments of the present invention, such as Figure 1-8 As mentioned above, when installing, firstly insert the screw end of the damper assembly 1 into the center hole of the liquid pipe fixing frame 10 and connect it with the connecting nut 3, then put the cover plate 11 on the damper 1, and then put the The double clevis 9 of the damper assembly 1 is connected to the lug plate or the connecting bolt of the cable trailer with a pin shaft, so that the whole set of liquid pipe trailer fixing device is placed under the cable trailer, and then the liquid pipes of the roadway are respectively placed on the In the corresponding grid, the clamping bolt 12 is penetrated from the bottom plate bolt hole of the liquid pipe towing fixing frame 10, and at the same time snapped into the U-shaped groove opening of the cover plate 11, and the clamping bolt 12 is tightened to realize the dragging of the liquid pipe. Fixed and connected with the cable trailer; when the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com