Shafting structure of self-lubricating turbocharger ball bearing

A turbocharger and self-lubricating technology, applied in the field of shafting lubrication, can solve problems such as bearing scratches, affecting the safe use of the engine, sintering or sealing system failure, etc., to solve the bearing radial and axial load, shafting Structural operation is stable and reliable, and the effect of excellent heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

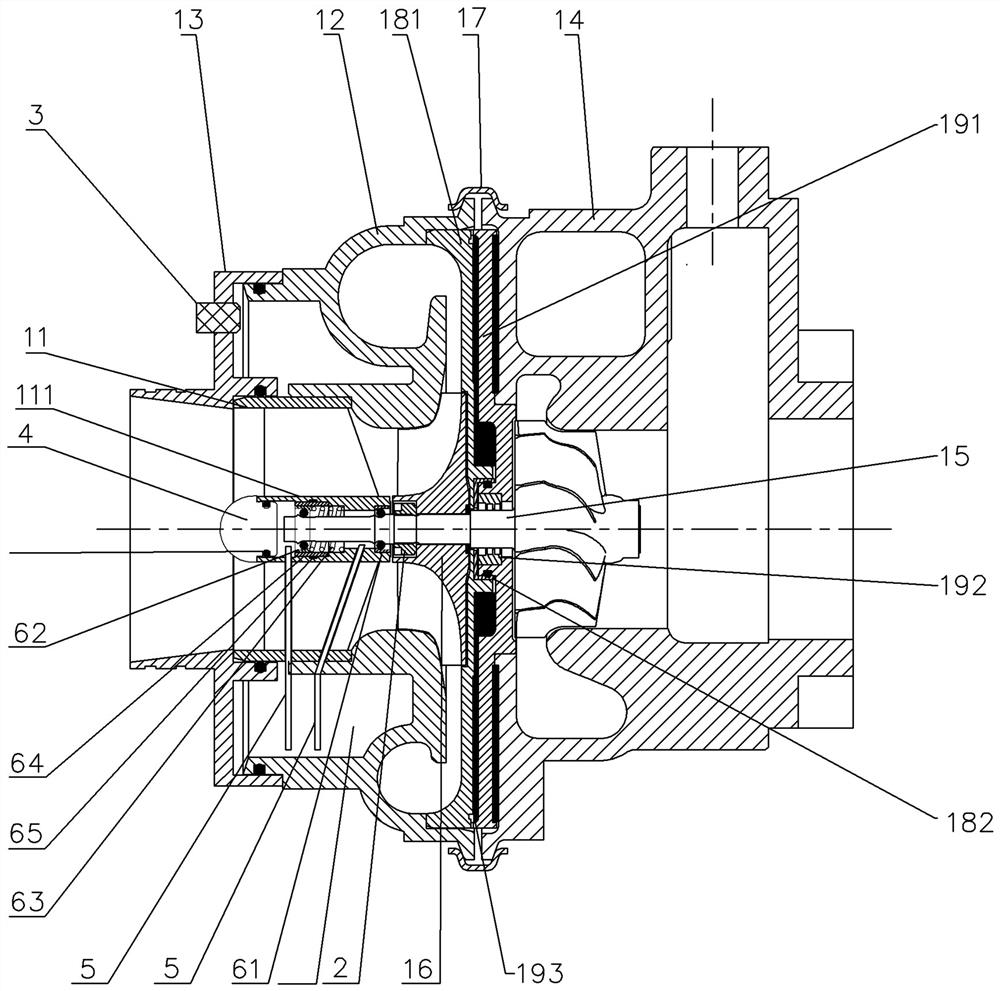

[0021] Such as figure 1 The shown turbocharger with self-lubricating ball bearing shafting structure includes bearing housing 11, compressor volute 12, oil seal cover 13, turbine case 14, rotor shaft 15, impeller 16 and back plate assembly, compressor The volute 12 and the turbine case 14 are connected as a whole by a clamp 17, the outer circumference of the bearing housing 11 is riveted (or inlaid) on the air inlet of the compressor volute 12, and the oil sealing cap 13 is set on the outer circumference of the end of the bearing housing 11. An oil storage chamber 2 is formed between the oil seal cover 13, the bearing seat 11 and the compressor volute 12, wherein the contact surface between the oil seal cover 13 and the compressor volute 12, and the contact surface between the oil seal cover 13 and the bearing seat 11 O-shaped sealing rings are installed at all places to ensure the sealing effect of the oil storage chamber 2. The oil sealing cover 13 is provided with a ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com