Cationic polymer nanoparticles encapsulating an active ingredients, and the cosmetic composition containing the same

A cationic polymer and nanocapsule technology, applied in cosmetic preparations, nanotechnology for materials and surface science, nanotechnology, etc., can solve human safety problems, reduce the stability of oil-soluble active components, increase the oil content Problems such as the relative surface area of the soluble component capsules, etc., to achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Hereinafter, each step of an example of the preparation method of the cationic polymer nanocapsules with surface potential of the present invention will be described in detail.

[0026] 1) The step of preparing a hydrophobic functional polymer with a cationic functional group capable of absorbing active components:

[0027] In the present invention, the preparation of the polymer having cationic functional groups is carried out using an emulsifier-free emulsion polymerization method.

[0028]In the present invention, in order to impart cationic properties to the polymer, it is preferable to use a radical polymerizable cationic monomer, or a low molecular weight polymer having a molecular weight of 400-800. Specific examples of such monomers and polymers may include 2-vinylpyridine, 3-vinylpyridine, 4-vinylpyridine, acrylamide, (meth)acrylamide, vinylpyrrolidone, vinyl-N-methyl Pyridine chloride, 3-methacryloyl-2-ethyl-tetraalkylammonium chloride (3-methacryloyl-2-ethyl...

Embodiment 1

[0051] A butyl methacrylate random copolymer was prepared in the following manner. Based on the weight of the polymer, 75% by weight of butyl methacrylate was mixed with 25% by weight of (methacryloyl)ethyl diethylamine. The mixture was added to 0.5% 2,2′-azobis(2-methylpropylamidine) dihydrochloride aqueous solution, and polymerized at 70° C. under a nitrogen atmosphere for 4 hours under stirring at 250 rpm, Thus, a polymer latex was obtained. The prepared polymer was precipitated with sodium chloride to obtain a powder. The powder was recrystallized from acetone / water to remove unreacted monomer and reprecipitated with sodium chloride to give a powder. The powder was filtered and washed with water, and this filtering and washing process was repeated several times. The resulting material was dried in a vacuum oven, whereby powdered capsules were obtained.

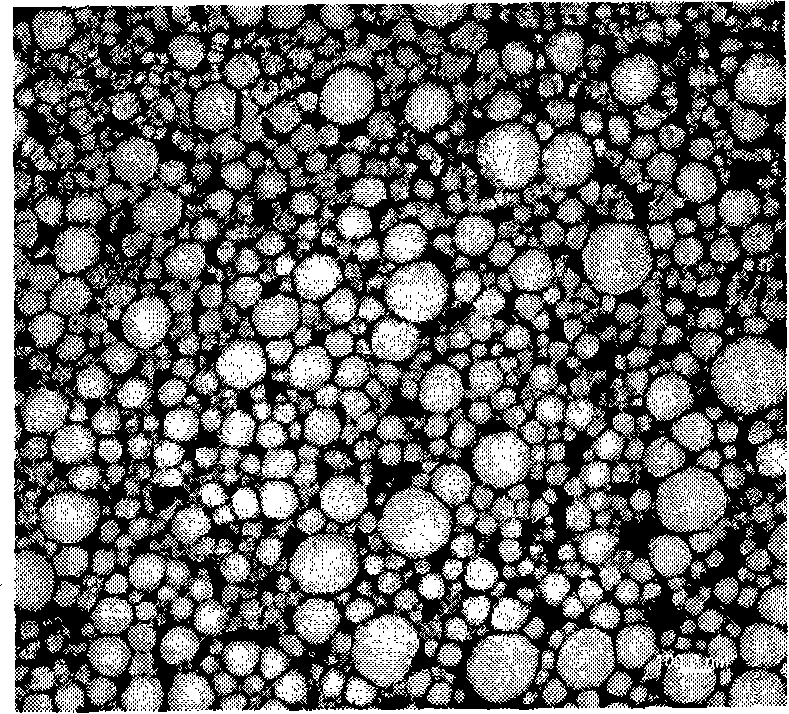

[0052] To prepare nanocapsules encapsulating Coenzyme Q-10, 2 g of the polymer having cationic functional groups pre...

Embodiment 2

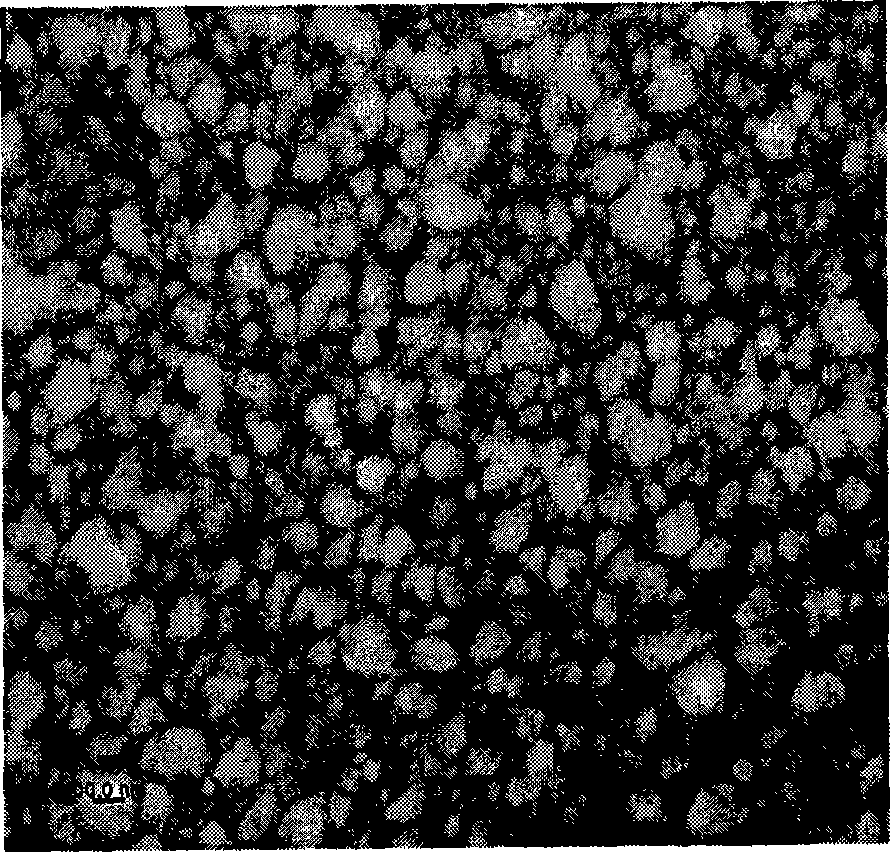

[0054] Polymers and capsules were prepared according to the method of Example 1, except that methyl methacrylate was used to prepare a random copolymer of methyl methacrylate with cationic functional groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com