Automatic transmission and shift control method for said transmission

A technology of automatic transmission and transmission, which is applied in the direction of transmission control, transmission, and components with teeth, etc. It can solve the problems of increasing the difficulty of moving out of the load gear and synchronizing and moving into the target gear, and the impossibility of transmission modification, so as to avoid Delay or acceleration, comfortable running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

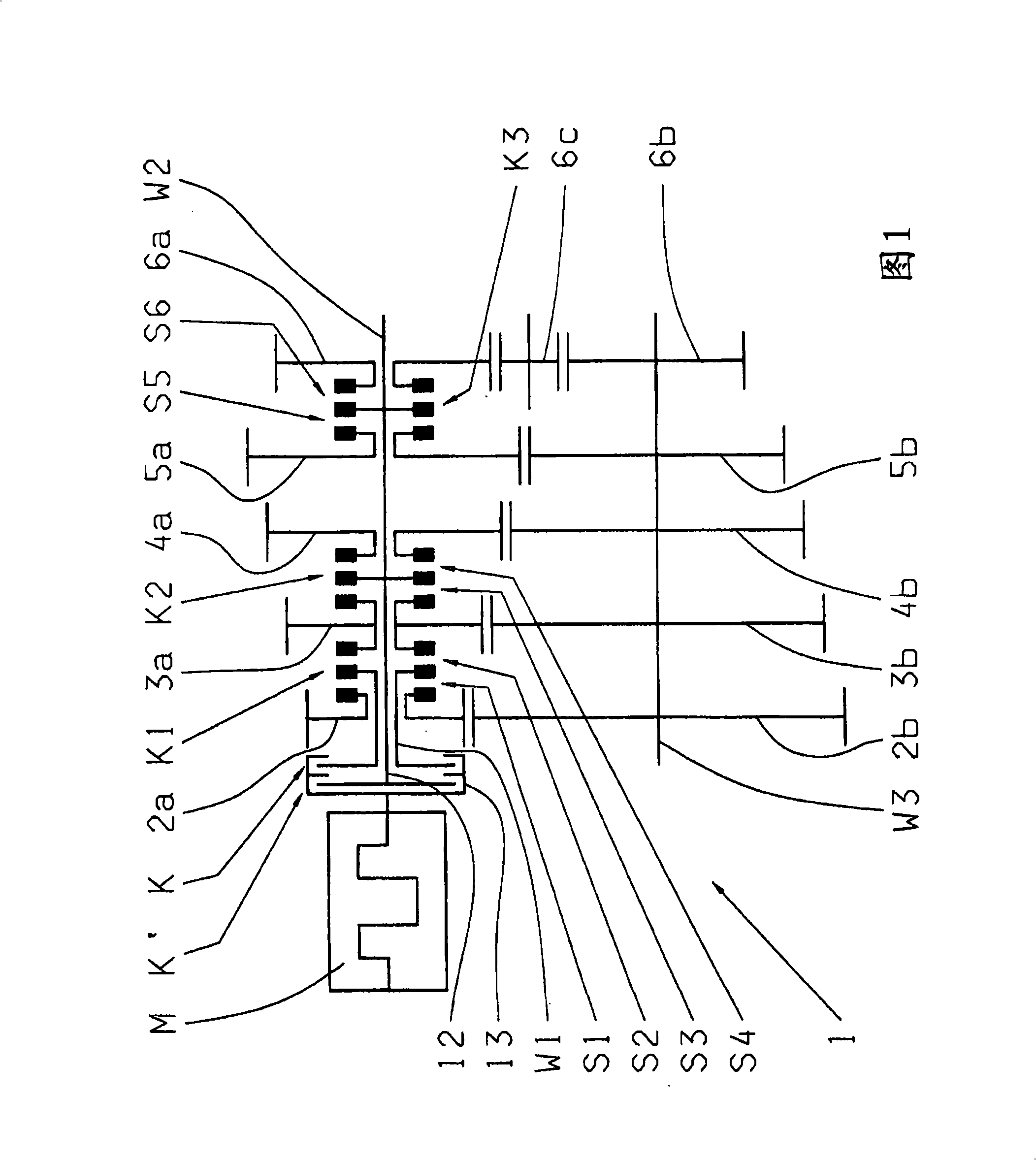

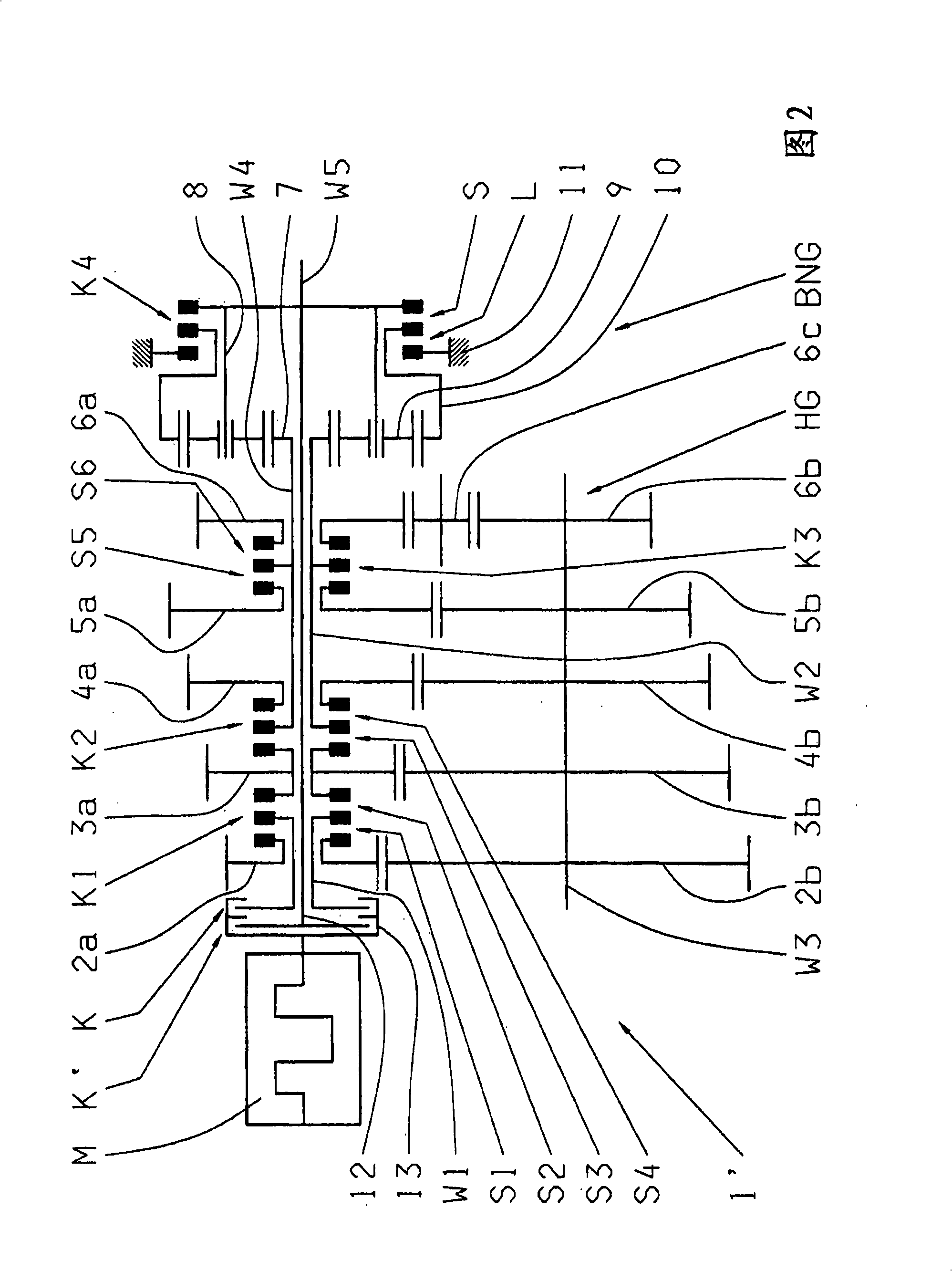

[0026] An automatic transmission 1 as shown in FIG. 1 constitutes a single intermediate shaft transmission, which has an input shaft W1, an output shaft W2 coaxially arranged with the input shaft, and an intermediate shaft W3 arranged parallel to the two transmission shafts W1, W2. An input shaft W1 of the transmission 1 is connected to a drive motor M constituting an internal combustion engine through an engageable and disengageable engine clutch K. The transmission 1 has four selectively shiftable forward gears and one reverse gear.

[0027] In order to shift gears, the input shaft W1 can be connected to the floating wheel 2a of the first gear pair 2a, 2b in the gear position S1 through the first shifting clutch K1 inside the transmission, because the fixed wheel 2b is firmly connected to the intermediate shaft W3 connected, thus establishing a transmission connection between the input shaft W1 and the intermediate shaft W3. Furthermore, as an alternative, the input shaft W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com