Method, device and equipment for vehicle shifting

A gear shifting method and vehicle technology, which is applied in the field of vehicle power systems, can solve the problems of reducing the speed of motors and clutches, high motor speeds, and easy shifting shocks, etc., to achieve the effect of improving ride comfort and realizing the shifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

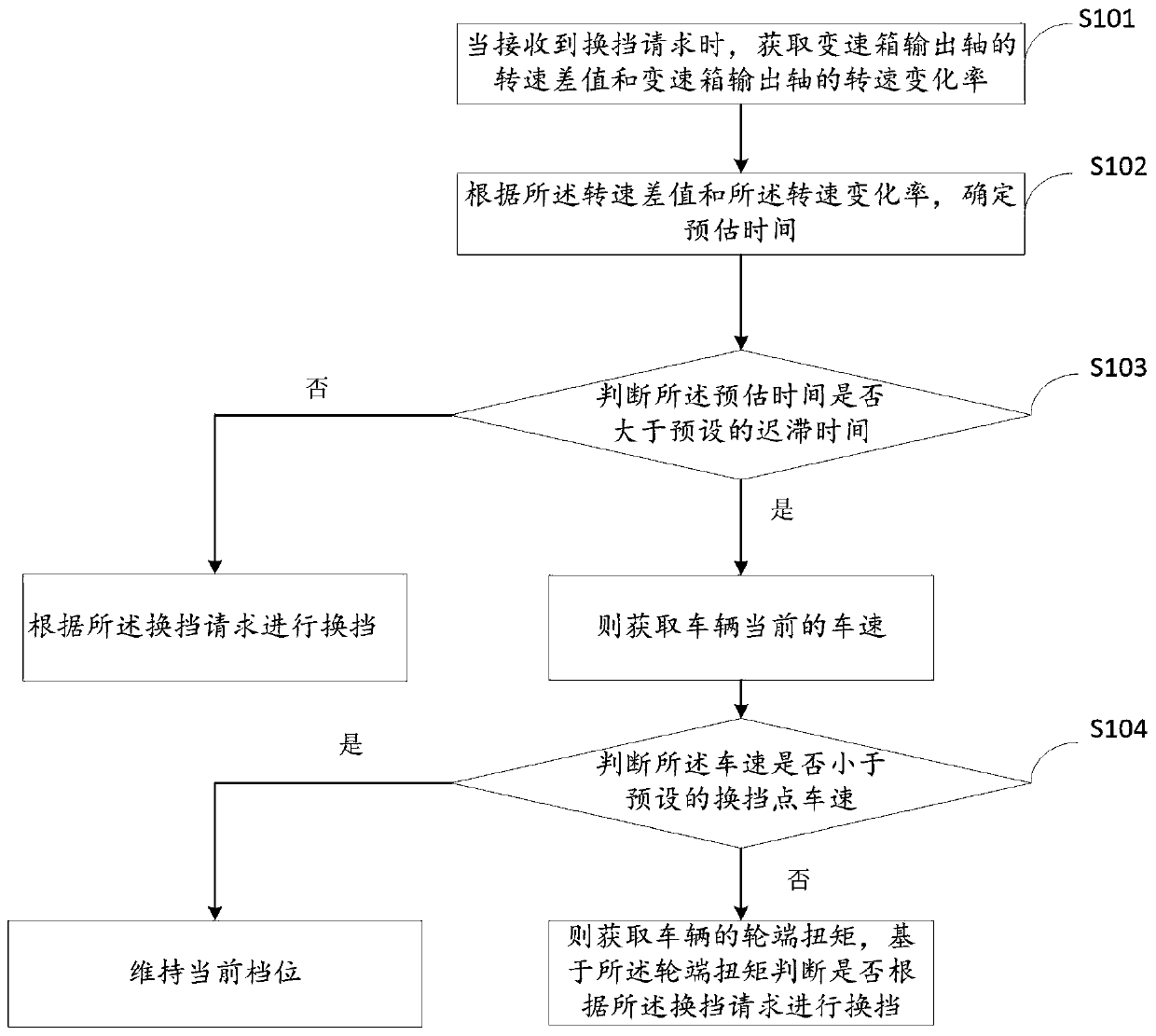

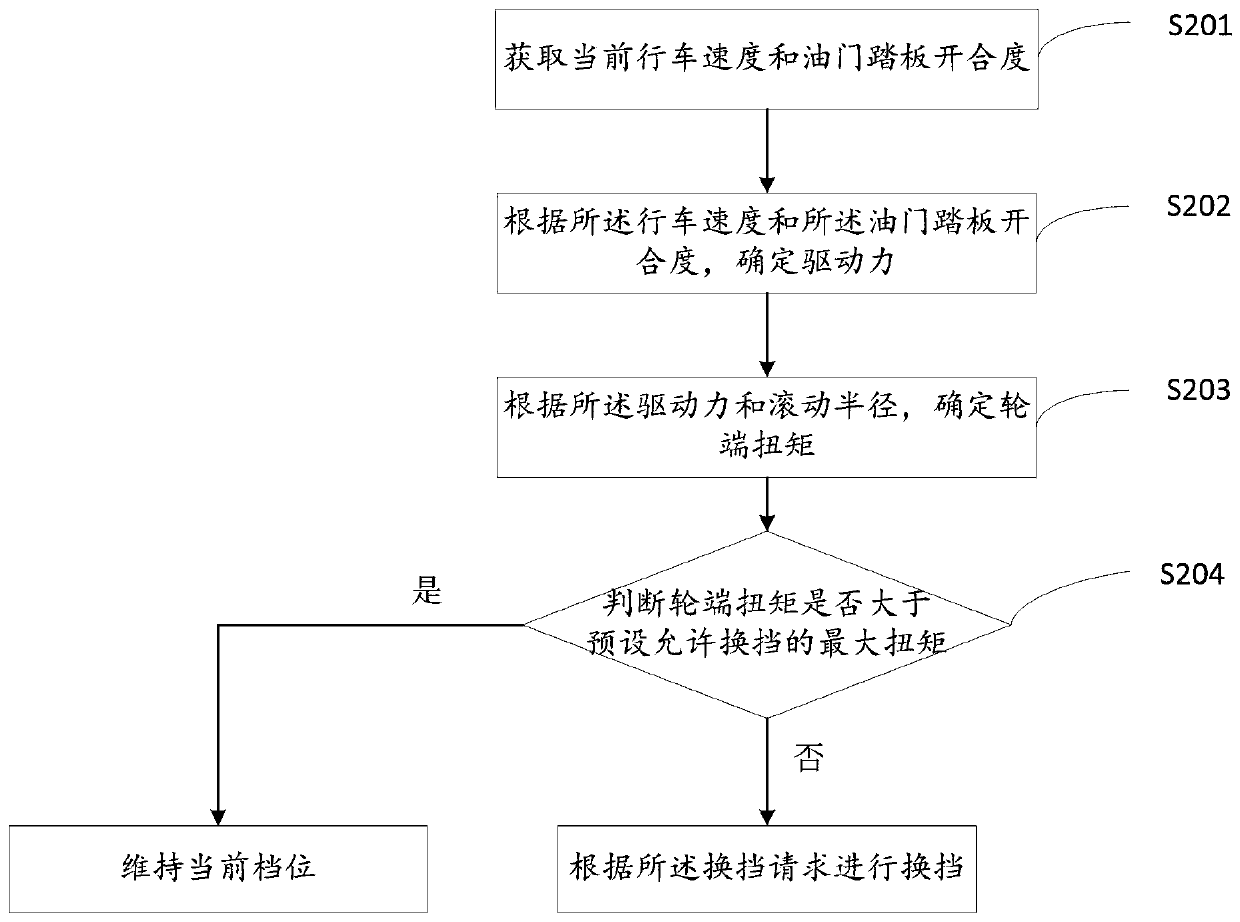

[0064] Embodiment 1 provides a vehicle gear shifting method, combining figure 1 and figure 2 shown, including:

[0065] S101. When a gear shift request is received, acquire the rotational speed difference of the transmission output shaft and the rotational speed change rate of the transmission output shaft.

[0066] Specifically, the rotational speed difference includes:

[0067] Obtain the speed limit value of the gearbox output shaft overdrive and the current speed of the gearbox output shaft;

[0068] Based on the rotational speed limit value and the rotational speed, a rotational speed difference of an output shaft of the gearbox is determined.

[0069] Further, the difference between the rotational speed limit value of the overdrive of the transmission output shaft and the current rotational speed of the transmission output shaft is the rotational speed difference of the transmission output shaft.

[0070] Further, the speed limit value includes:

[0071] Get the cu...

Embodiment 2

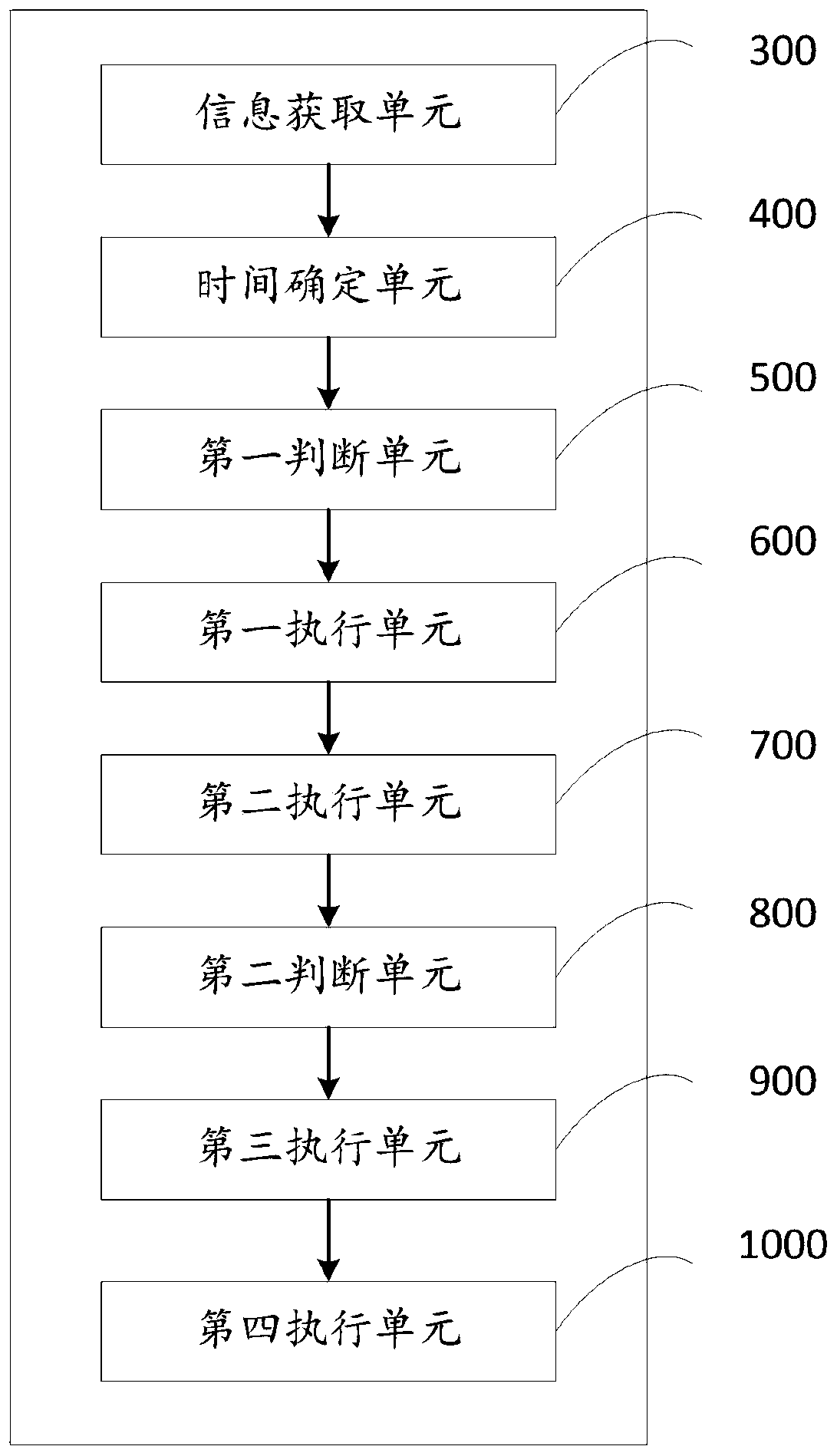

[0101] The second embodiment provides a vehicle gear shifting device, such as image 3 shown, including:

[0102] The information acquiring unit 300 is configured to acquire the rotational speed difference of the transmission output shaft and the rotational speed change rate of the transmission output shaft when a shift request is received;

[0103] A time determination unit 400, configured to determine an estimated time according to the rotational speed difference and the rotational speed change rate;

[0104] A first judging unit 500, configured to judge whether the estimated time is greater than a preset lag time;

[0105] The first execution unit 600 is configured to perform gear shifting according to the gear shift request when the estimated time is not greater than the lag time;

[0106] The second execution unit 700 is configured to acquire the current vehicle speed of the vehicle when the estimated time is greater than the lag time;

[0107] The second judging unit ...

Embodiment 3

[0131] Embodiment 3 provides a vehicle gear shifting device, including: a data acquisition device, a motor controller, a gearbox controller, and a clutch controller;

[0132] The data collection device is used to collect the current vehicle speed and the current motor speed of the vehicle;

[0133] The gearbox controller is used to determine the speed difference of the gearbox output shaft and the speed change rate of the gearbox output shaft;

[0134] The gearbox controller is used to determine the estimated time according to the speed difference of the gearbox output shaft and the speed change rate of the gearbox output shaft;

[0135] The gearbox controller is used to judge whether the estimated time is greater than a preset delay time; if the estimated time is not greater than the delay time, perform gear shifting according to the shift request; If the estimated time is greater than the lag time, then the wheel end torque of the vehicle is obtained, and based on the wheel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com