Wood veneer surfaced decorative laminate product and method of making same

A wood veneer and laminate technology, which is applied in the manufacture of thin wood chips, the joining of wooden veneers, and layered products, etc. It can solve the problems that the fidelity of the natural color of the wood grain is easy to fade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

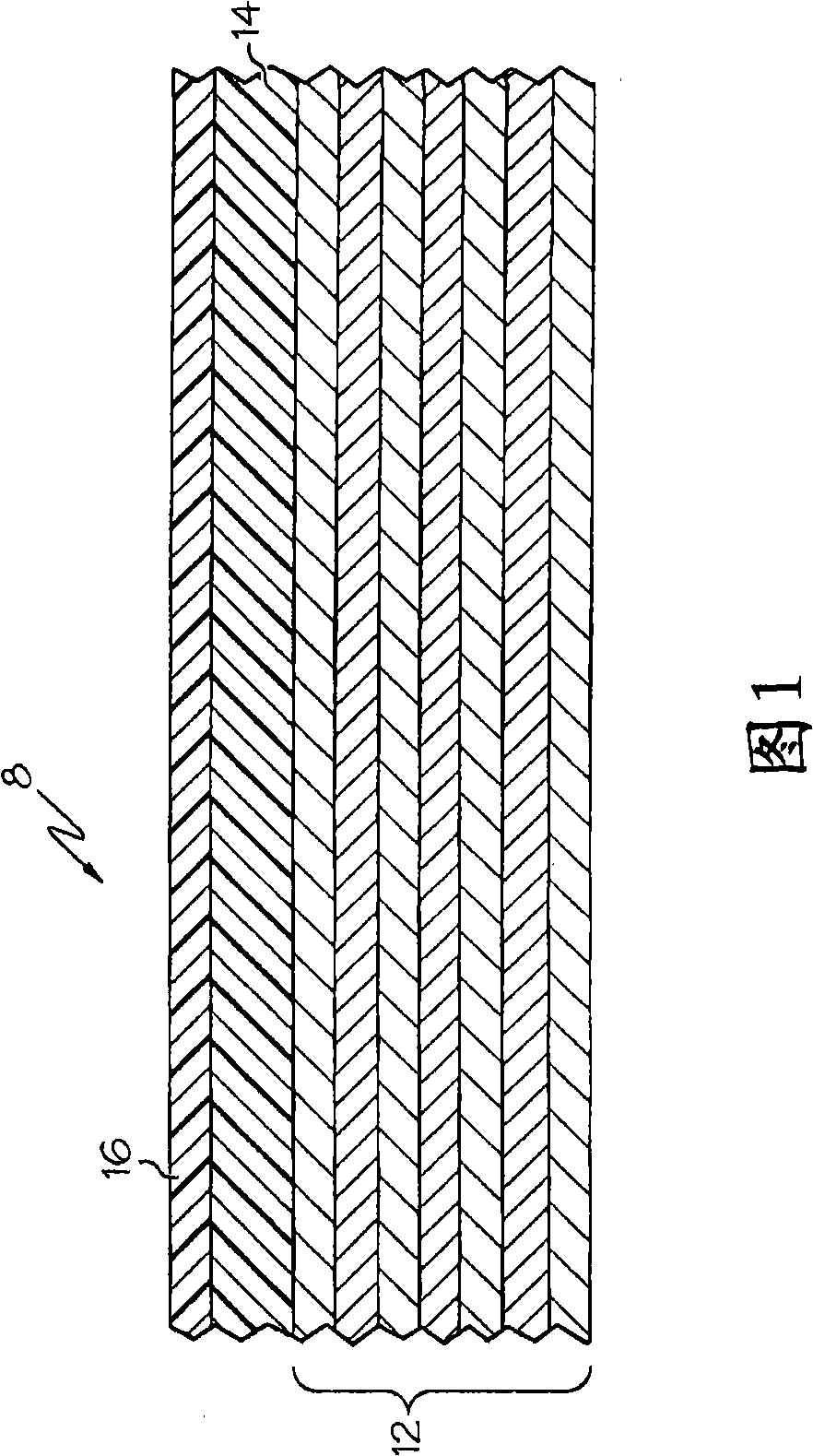

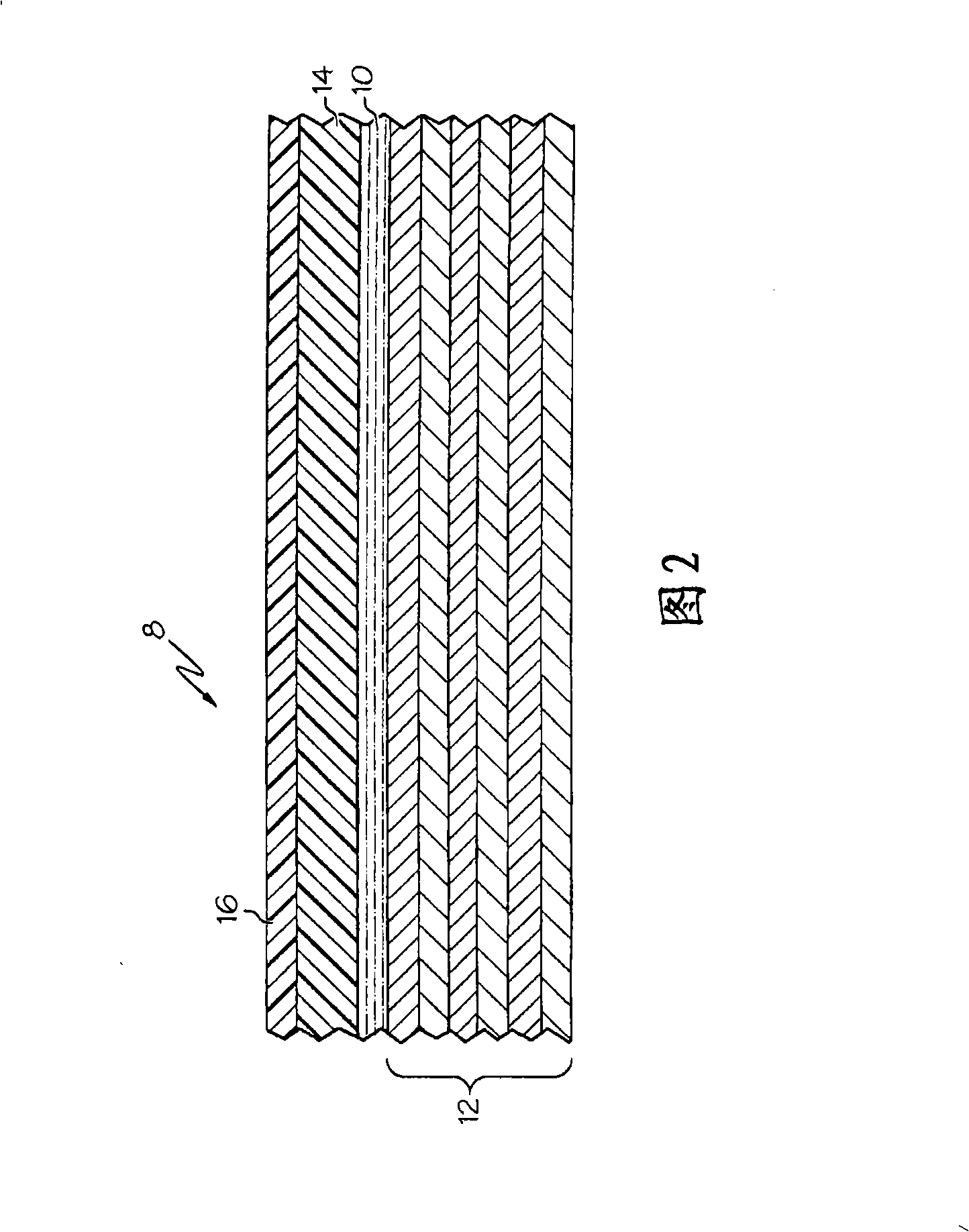

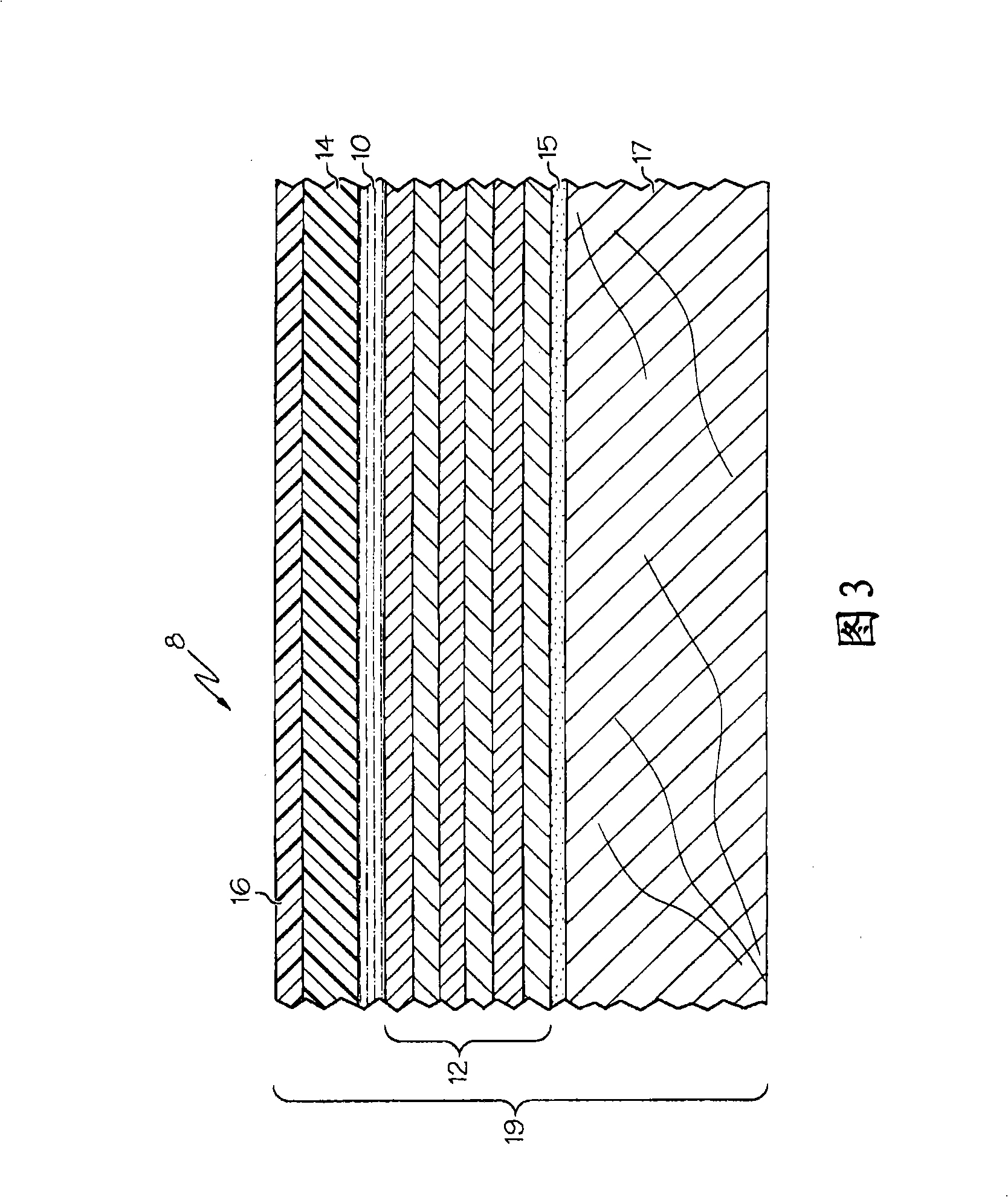

[0021] Referring initially to Figure 1, one embodiment of a wood veneer veneered decorative laminate 8 is shown. The laminate comprises a core 12, a resin-impregnated piece of wood veneer 14 and a cured resin coating 16 on the wood veneer. As shown, the core panel 12 of the laminate comprises one or more layers of paper sheets, such as kraft paper, that have been impregnated with a thermosetting liquid thermosetting resin, such as phenol formaldehyde resin or melamine formaldehyde resin. The core provides a structurally reinforced base for the laminate.

[0022] A preferred construction for the core ply consists of about 2-20 sheets of kraft paper having a basis weight of 80-250 grams per square meter (gsm), wherein the kraft paper is impregnated with phenolic resin, melamine resin or mixtures thereof. Typically, the liquid aqueous resin solution will have a solids content of from about 40% to about 70% and a water content of from about 30% to about 60%. As will be appreciat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com