Carboxyl-terminated polyester resin modified epoxy resin and preparation method thereof, electrophoretic coating and preparation method thereof

A carboxyl-terminated polyester and epoxy resin technology, applied in electrophoretic coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as unsatisfactory corrosion resistance and poor coating adhesion, and achieve leveling Enhanced performance, good durability, and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

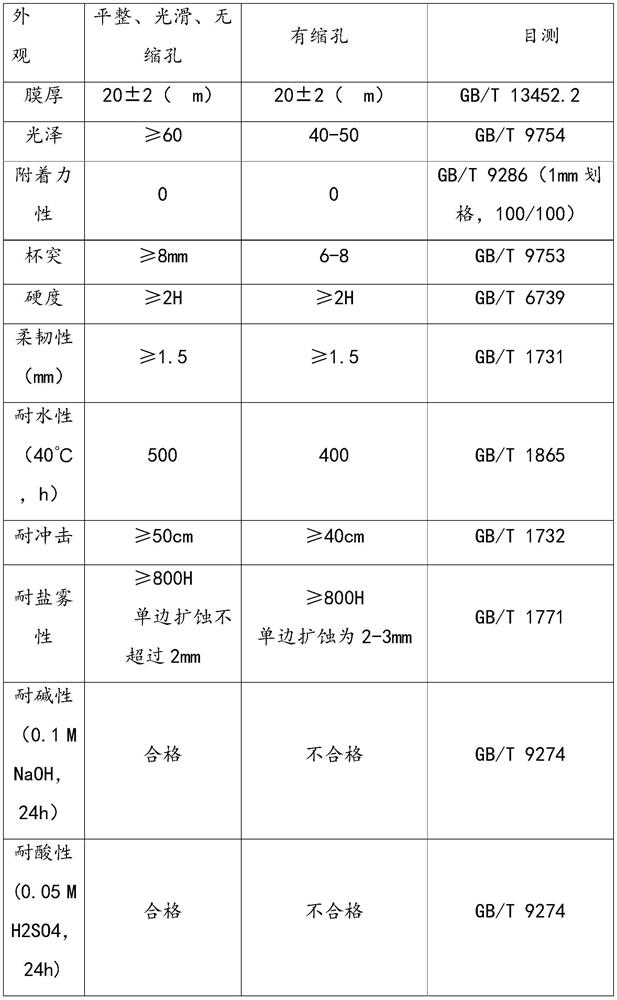

Examples

preparation example Construction

[0093] In a second aspect, in at least one embodiment, a method for preparing a carboxyl-terminated polyester resin modified epoxy resin is provided, comprising the following steps:

[0094] (a) Epoxy resin and bisphenol A are mixed homogeneously and heated, add basic catalyst and keep warm for a period of time, obtain polyepoxide;

[0095] (b) adding carboxyl-terminated polyester resin to the obtained polyepoxide, then adding a basic catalyst, and reacting to obtain mixture A;

[0096] (c) adding methyl isobutyl ketone and a basic catalyst to the cooled mixture A, heating and reacting to obtain mixture B;

[0097] (d) adding a hyperbranched isocyanate curing agent to the cooled mixture B, and cooling after a period of heat preservation to obtain a carboxyl-terminated polyester resin modified epoxy resin;

[0098] Preferably, in step (a), the heating temperature is 130-135°C, the holding temperature is 140-145°C, and the holding time is 4-6h;

[0099] Preferably, the reactio...

Embodiment 1

[0150] A carboxyl-terminated polyester resin modified epoxy resin, mainly prepared from the following raw materials in parts by weight:

[0151] 50 parts of carboxyl-terminated polyester resin, 700 parts of bisphenol A epoxy resin, 250 parts of bisphenol A, 260 parts of methyl isobutyl ketone, 30 parts of hyperbranched isocyanate curing agent, N,N-dimethylbenzylamine 1.0 parts, 40 parts of N-methylethanolamine and 19 parts of ketimine of amine ethylethanolamine.

[0152] The carboxyl-terminated polyester resin is mainly prepared from the following raw materials in parts by weight: 30 parts of propylene oxide, 0.2 parts of triethanolamine, 20 parts of formic acid and 45 parts of maleic anhydride.

[0153] The hyperbranched isocyanate curing agent is mainly prepared from the following raw materials in parts by weight: 40 parts of hexamethylene diisocyanate trimer, 45 parts of trimethylolpropane, 20 parts of methyl isobutyl ketone and dibutyltin dilaurate 0.5 servings.

Embodiment 2

[0155] A carboxyl-terminated polyester resin modified epoxy resin, mainly prepared from the following raw materials in parts by weight:

[0156] 200 parts of carboxyl-terminated polyester resin, 650 parts of bisphenol A epoxy resin, 300 parts of bisphenol A, 220 parts of methyl isobutyl ketone, 50 parts of hyperbranched isocyanate curing agent and 100 parts of N-methylethanolamine.

[0157] The carboxyl-terminated polyester resin is mainly prepared from the following raw materials in parts by weight: 32 parts of propylene oxide, 0.3 parts of triethanolamine, 22 parts of formic acid and 45 parts of maleic anhydride.

[0158] The hyperbranched isocyanate curing agent is mainly prepared from the following raw materials in parts by weight: 44 parts of hexamethylene diisocyanate trimer, 43 parts of trimethylolpropane, 22 parts of methyl isobutyl ketone and dibutyltin dilaurate 0.5 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com