A composite super anti-corrosion anti-seepage wall material and its application method

A wall material and anti-seepage technology, applied in water conservancy projects, sea area projects, artificial islands, etc., can solve the problems of cement soil corrosion, wall cracks, leakage, etc., and achieve the effect of ensuring integrity and reducing connection points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

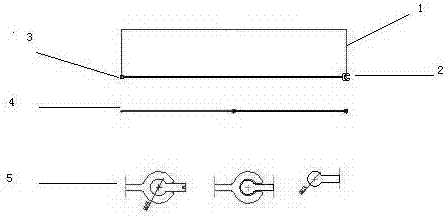

[0027] Composite ultra-strong anti-corrosion and seepage-proof wall material production: see figure 1 , with PVC as the main material, adding several kinds of additives, after stirring and high temperature, it is extruded into a flat plate through a mold. The wall material is 800mm wide, 6mm thick, and 12000mm long; there are connecting devices on both sides of the wall material, and one It is a groove, and one side is a convex groove. When using it, use special equipment to insert the convex groove of the rear wall material into the groove of the front wall material that has been constructed, so that the front and rear wall materials are connected to each other to form an anti-corrosion and water-proof curtain. system.

[0028] Composite ultra-strong anti-corrosion and anti-seepage wall materials Application places: anti-seepage and anti-corrosion of walls.

[0029] Composite ultra-strong anti-corrosion and anti-seepage wall materials. Use special construction equipment for...

Embodiment 2

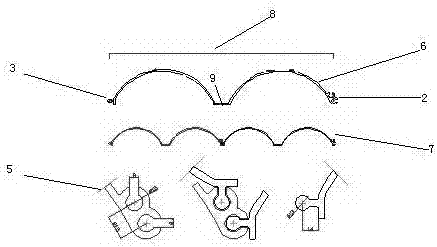

[0038] Composite ultra-strong anti-corrosion and anti-seepage wall materials. see figure 2 , with PVC as the main material, adding several kinds of admixtures, after stirring and high temperature, it is extruded into a double-curved arch wall material through a mold. The length of the material is 5000mm; there are connecting devices on both sides of the wall material, one side is a groove, and the other side is a convex groove. When using it, use special equipment to insert the convex groove of the back wall material into the groove of the front wall material that has been constructed. Connect the front and rear wall materials to each other to form an anti-corrosion and waterproof curtain system

[0039] Composite ultra-strong anti-corrosion and anti-seepage wall materials Application places: Anti-corrosion and anti-seepage and rigid support for the wall of the first-floor basement with a depth of less than five meters. Using the arch principle of the wall material and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com