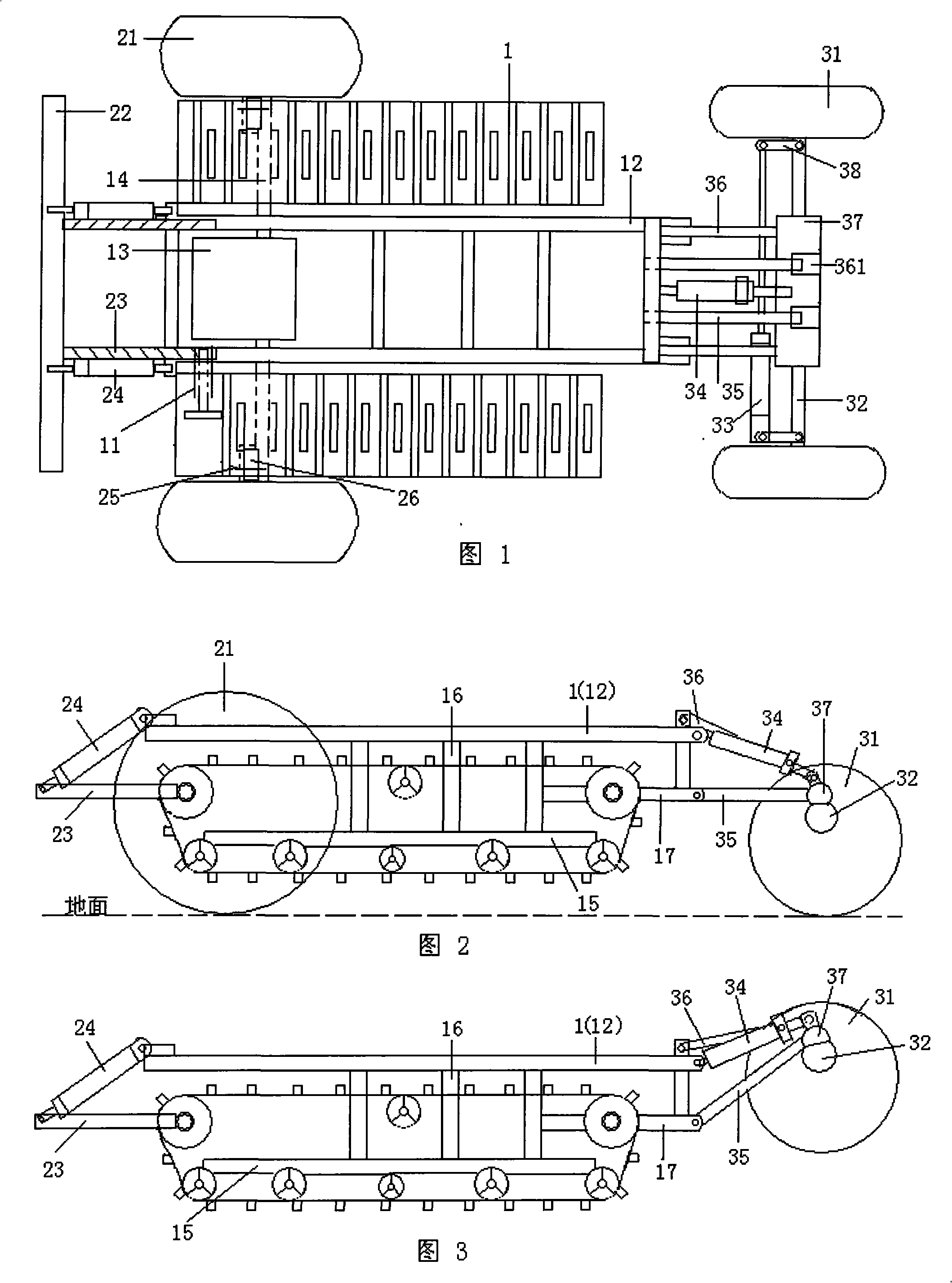

Caterpillar band harvester equiped with walking wheel

A harvester and walking wheel technology, which is applied in the field of agricultural machinery, can solve the problems of high friction, shortened service life of crawler tracks, and increased harvesting costs, and achieve the effects of prolonging service life, increasing input costs, and reducing harvesting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] As shown in Figure 1, the detachable driving wheel train of the present invention is mainly made up of drive wheel 21, front platform 22, platform support rod 23 and front platform hydraulic cylinder 24, and platform support rod 23 has two, and their one end and front platform The platform 22 is connected, and the other end is flexibly connected with the shell of the crawler wheel shaft 11 of the crawler harvester 1; The chassis 12 is connected, and the other end is connected to the front platform 22; the drive wheel 21 is connected to the transmission output shaft 14 of the gearbox 13 of the crawler harvester 1 . Lift-and-release type direction wheel train of the present invention mainly is made up of direction wheel 31, rear axle 32, rear axle support frame and steering hydraulic oil cylinder 33, rear support oil cylinder 34. The rear axle support frame is connected between the rear axle and the crawler harvester chassis. rear axle support frame

[0015] It mainly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com