Novel three-dimensional weaving machine

A three-dimensional loom, a new type of technology, applied in looms, textiles, knitting, etc., can solve the problems of low performance of textile composite materials, incomplete interweaving of yarns, single structure of woven fabrics, etc., and achieve optimal interlayer shear strength, The effect of light weight and suitable toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

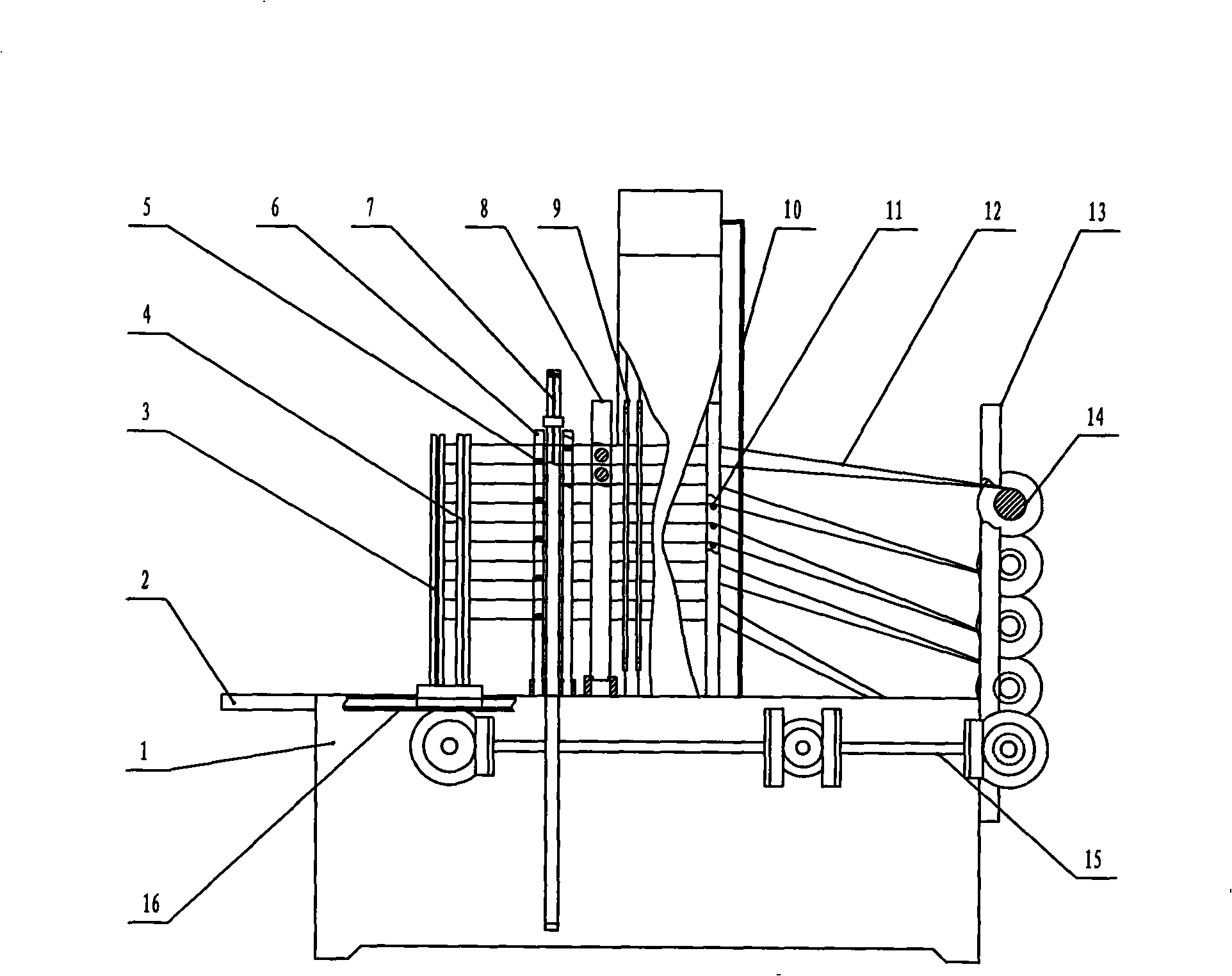

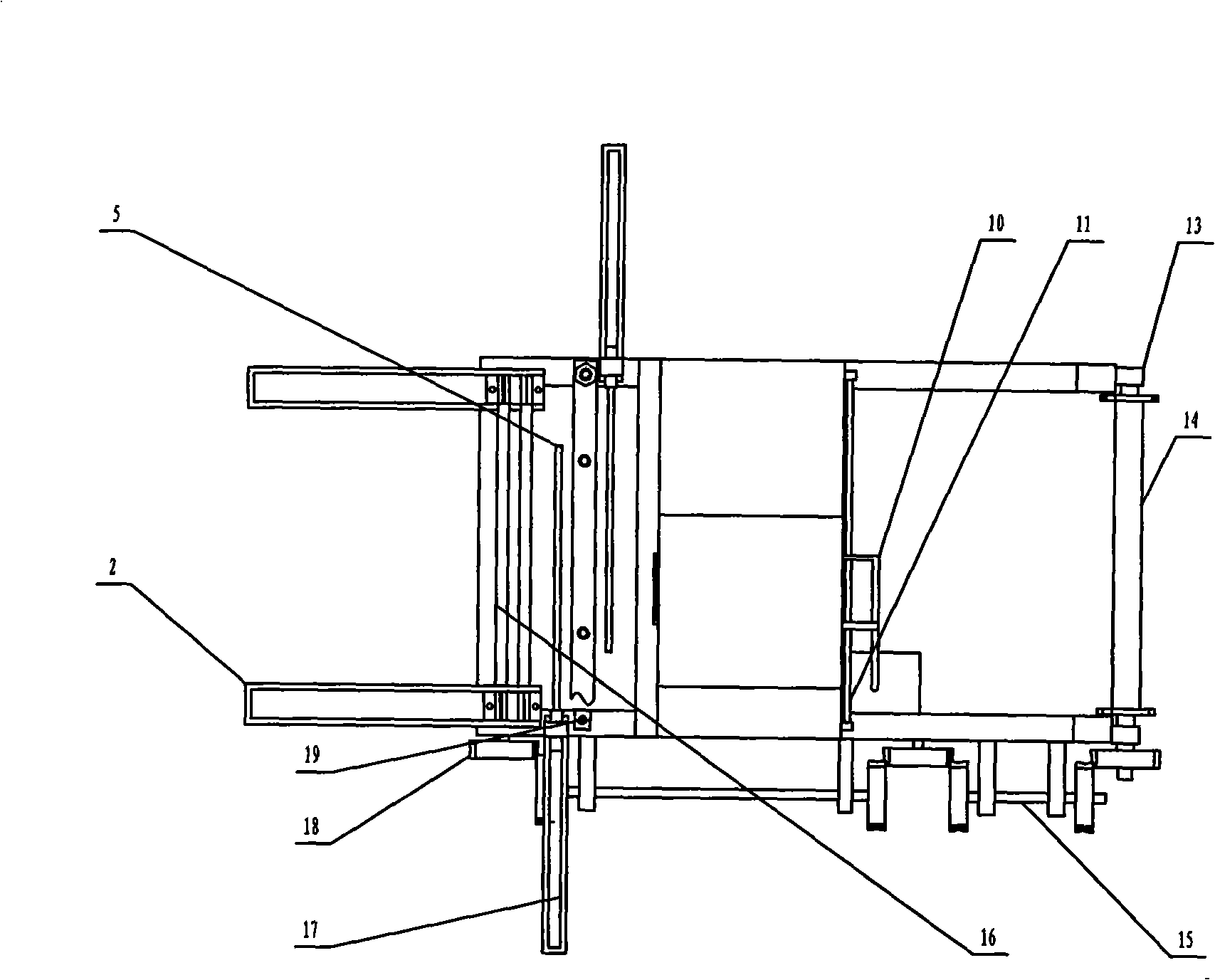

[0026] The invention adopts the general mechanical design method design, the main body is the frame, and the frame mainly includes four major mechanisms: a winding mechanism, an opening mechanism, a weft insertion mechanism, and a warp let-off mechanism.

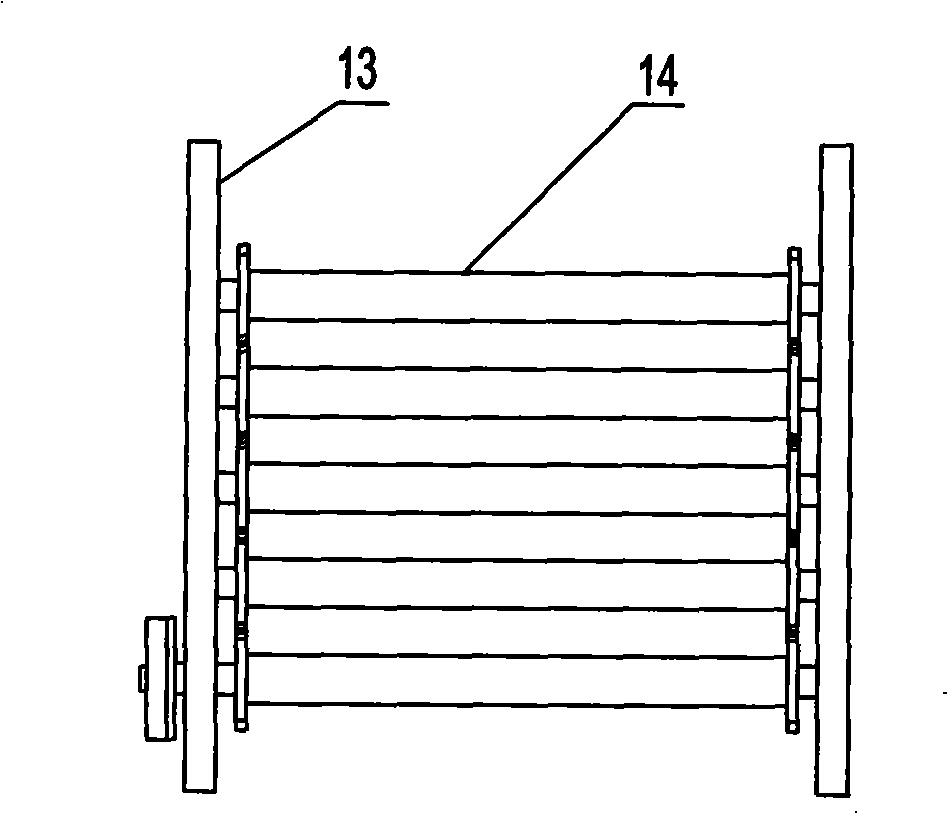

[0027] Such as figure 1 , figure 2 As shown, the two sets of winding guide rails 2 are in the shape of grooves and are fixed on both sides of the front end of the frame 1 by screws along the X direction. The yarn fixing plate 3 and the yarn dividing plate 4 are both composed of four long thin rods. The yarn dividing plate is fixed on the winding plate 16 along the Z-direction by a nut. The winding plate is locked in the groove of the winding rail and driven by a rack and pinion, so that it can move back and forth on the winding rail. The yarn fixing plate is used to fix the X-direction warp yarns and is the main source of crimping tension. The yarn dividing plate is the yarn dividing mechanism to ensure the hierarchy of yarns....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com