Combined support shield type comprehensive mining method

A combined support and mining method technology, applied in the field of mines, can solve the problems of low bearing capacity of pillars in wall caving method, loss of mine pillars and hidden dangers left in goaf, unsuitable for non-coal mine blasting mining, etc., and achieve good anti-corrosion Impact damage characteristics, on-site follow-up movement and long-term repeated use are reliable and convenient, and the effect of easy on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

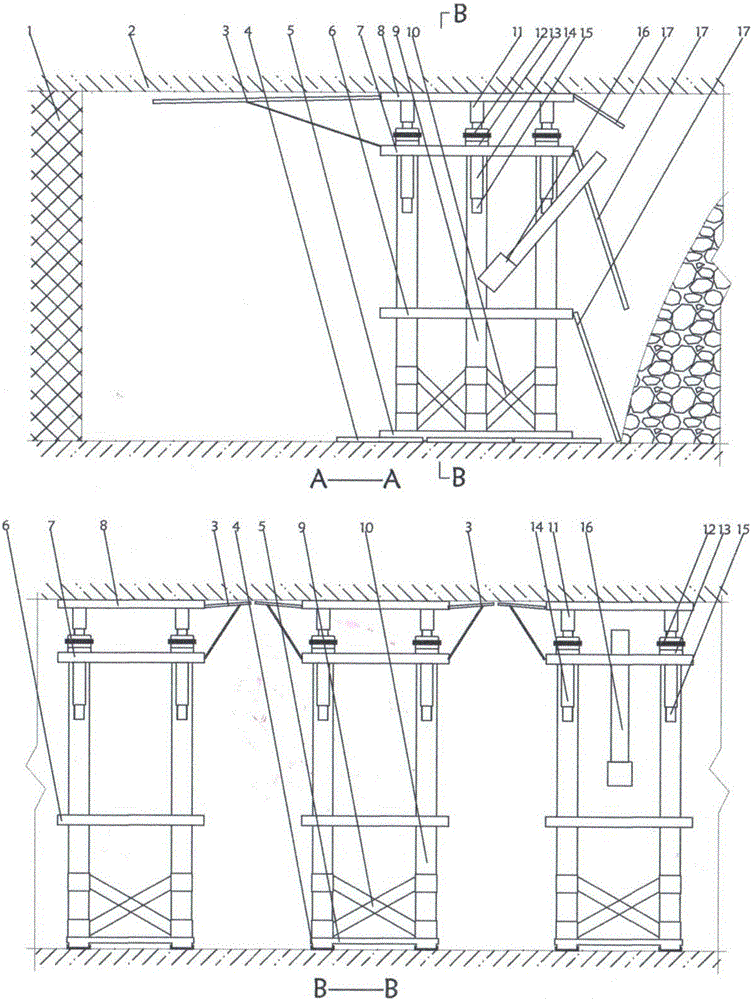

[0018] Mining method: starting from the middle section of the transport roadway or connecting roadway, along the ore body inclination or pseudo-inclination direction, close to the ore body floor and excavate the mining standard roadway uphill, and temporarily support it according to the stability of the surrounding rock; , install the combination bracket; if the two operation lines are pulled apart at the same time, then install double rows of combination brackets; line direction; the control of the width of the empty roof of the mining line: the width of the mining face of the mining line should generally be controlled within 4 meters, and the maximum distance between the combined support line and the stable mine wall should be controlled within 8 meters or by the surrounding rock of the roof. Stability is determined; when the length of the working line is too large, the combined support cable should be divided into multiple segments and followed up one by one to reduce the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com