Luffing jib maintaining valve for hydraulic shovel

A technology for hydraulic excavators and holding valves, which is applied to mechanically driven excavators/dredgers, etc., which can solve problems such as potential safety hazards, lowering of the boom, and accidents, and achieve the effect of reducing the sinking of the boom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

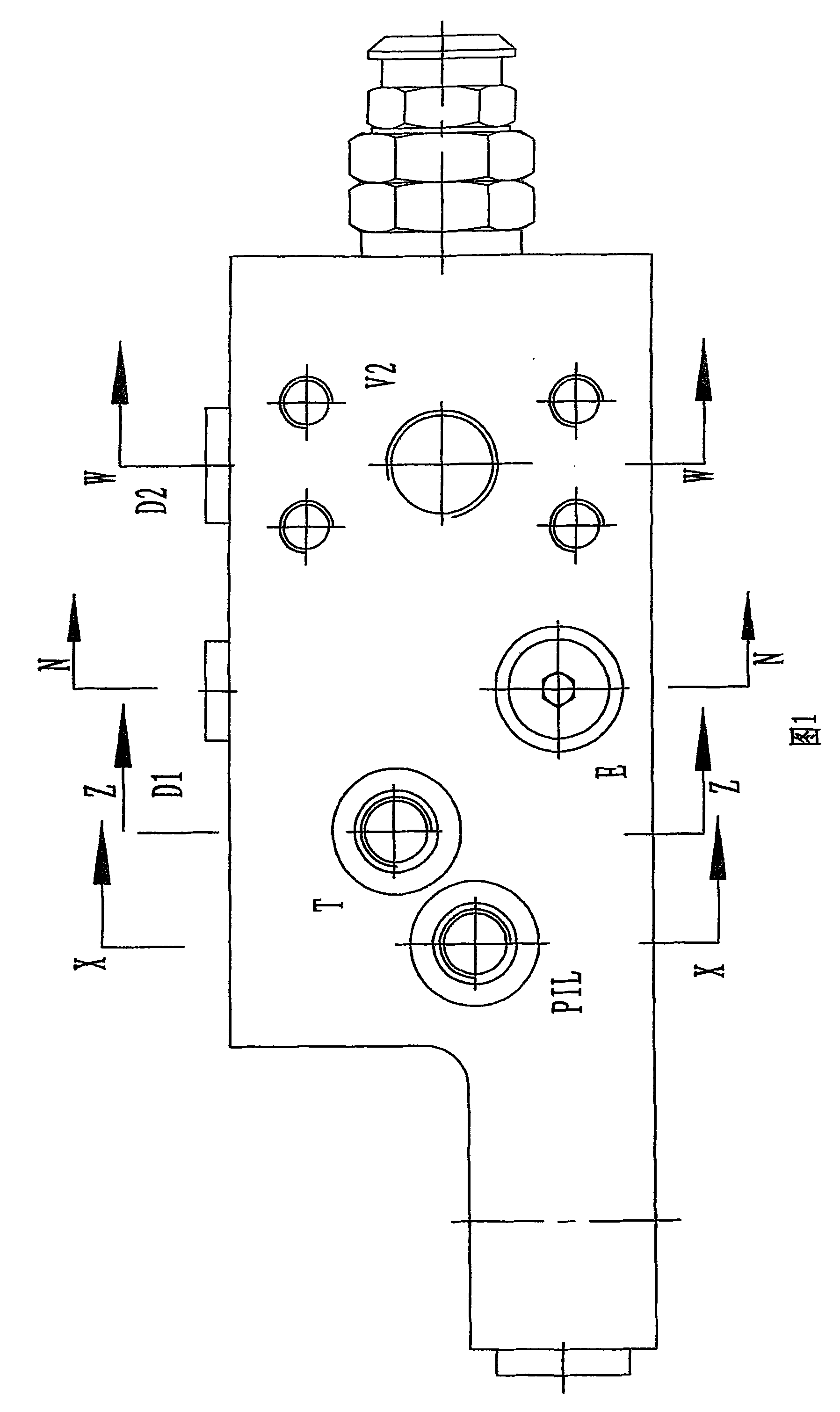

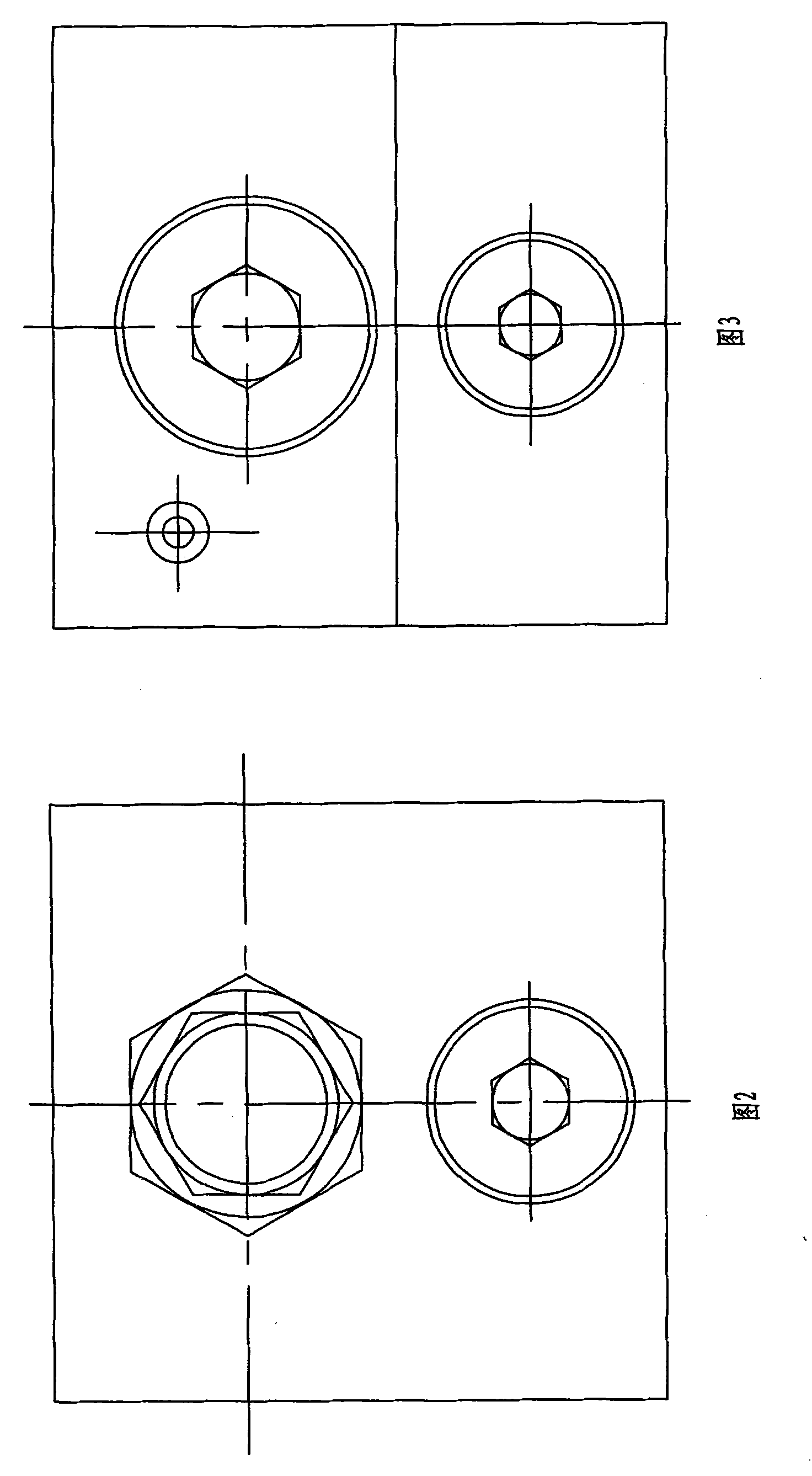

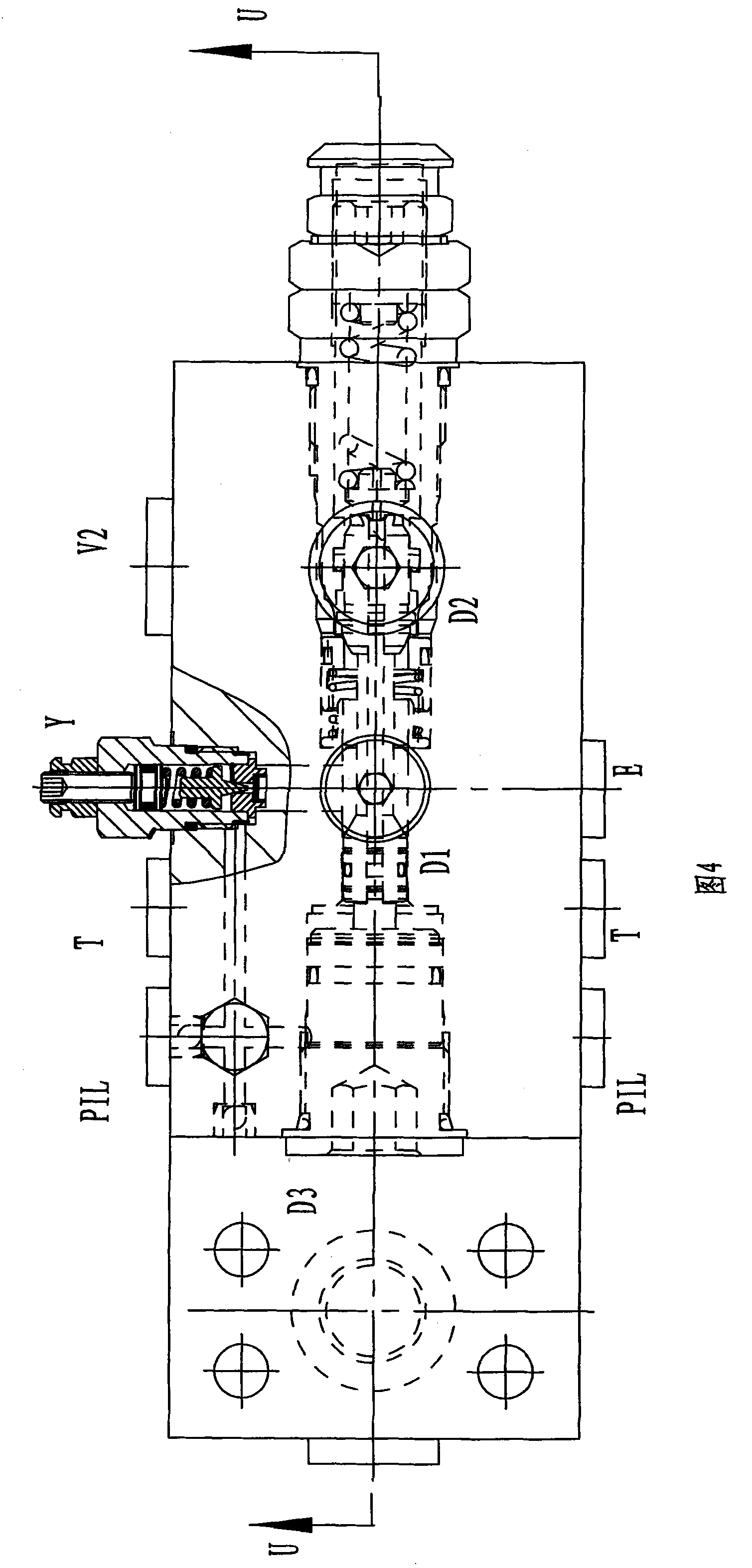

[0020] Such as Figure 1-9 , The present invention is a hydraulic excavator boom holding valve, including a valve block 1, the valve block 1 is opened with a first valve hole and a second valve hole, the first valve hole and the second valve hole are parallel to each other.

[0021] Piston 4, valve stem 6, left spring seat I8, spring I9, right spring seat I11 and holding valve 14 are arranged in the first valve hole from left to right, and the cone core I20 of holding valve 14 is connected with the valve stem 6. Connected, the outer edge of the cone core I20 is provided with an O-ring IV21 and a retaining ring I22, the right end is provided with an O-ring III19, the outer edge of the piston 4 is provided with a combined sealing ring I5, and the outer edge of the right spring seat I11 is provided with a combined sealing ring III10, the left end of the first valve hole is screwed with a plug I2, and an O-ring I3 is embedded in the outer edge of the plug I2. The valve hole where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com