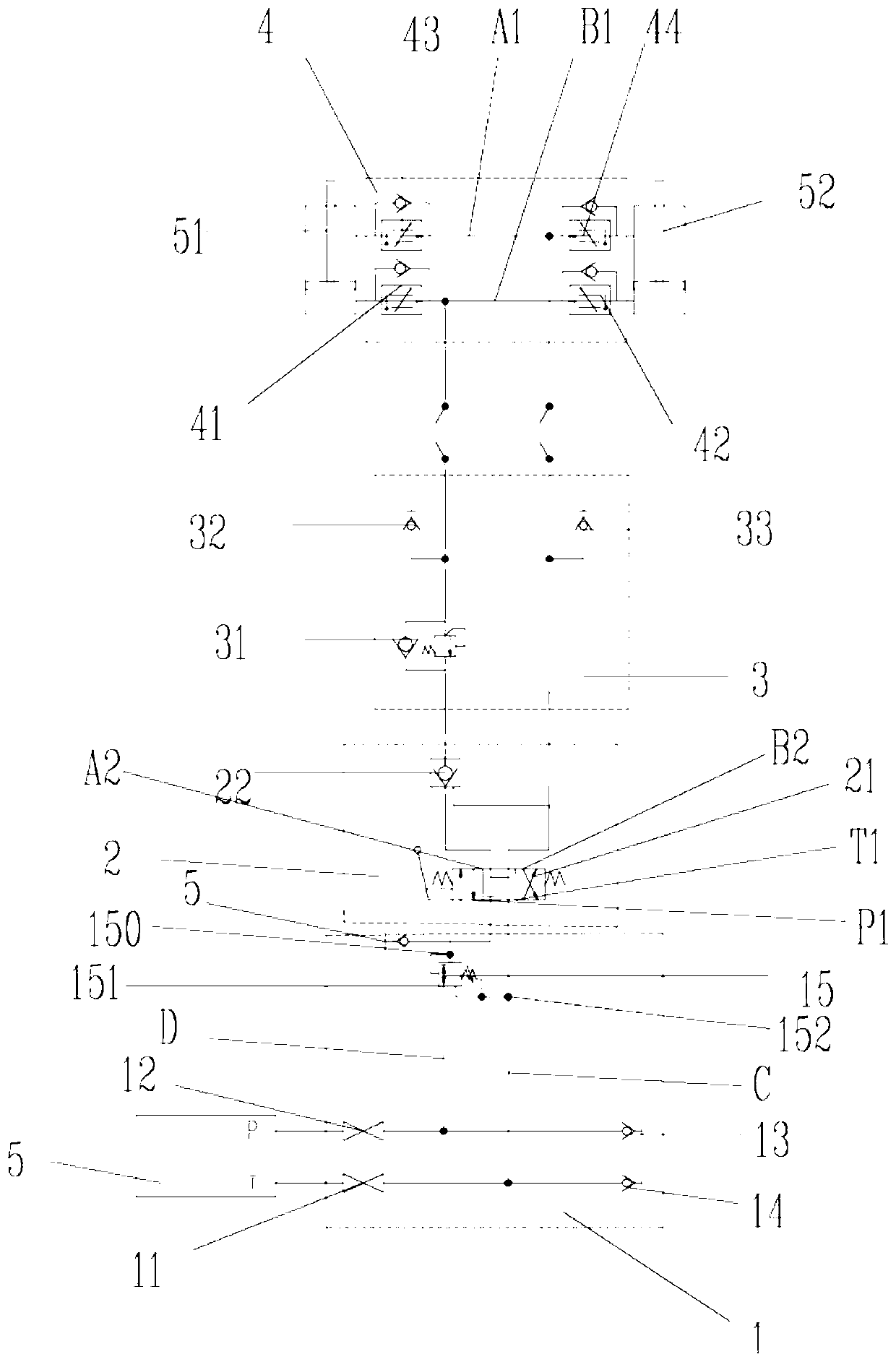

Hydraulic control system of roller dismounting manipulator

A hydraulic control system and manipulator technology, which is applied in the field of hydraulic control, can solve problems such as unsynchronized movements of jacking hydraulic cylinders, affecting the normal operation of roll removal manipulators, and unsmooth movement of bracket devices, so as to facilitate inquiries and prevent natural slides , to prevent the effect of natural sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0033] The main oil return pipeline C communicates with the first pipeline A1 through the manual reversing valve 21, and the main oil supply pipeline D communicates with the second pipeline B1 through the manual reversing valve 21. The two sets of pipelines can both output Oil can also be input into oil. The hydraulic control system of the roll dismantling manipulator controls the lifting action of the jacking hydraulic cylinder by the manual reversing valve 21 and four one-way speed regulating valves. The one-way speed regulating valve itself is a kind of pressure and temperature compensation. Type valve, which can maintain a stable flow, does not change with system pressure and temperature, and saves time and effort for adjustment. Using it to control the flow in the hydraulic circuit can precisely control the lifting speed of the jacking hydraulic cylinder, thus ensuring the synchronization between different hydraulic cylinders. The combined check valve can make the liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com