A bop transfer device suitable for deep sea floating drilling

A moving device and floating technology, applied in the field of BOP moving devices, can solve the problems of instability, high cost, low safety factor, etc., and achieve the effects of preventing natural slippage, high reliability, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

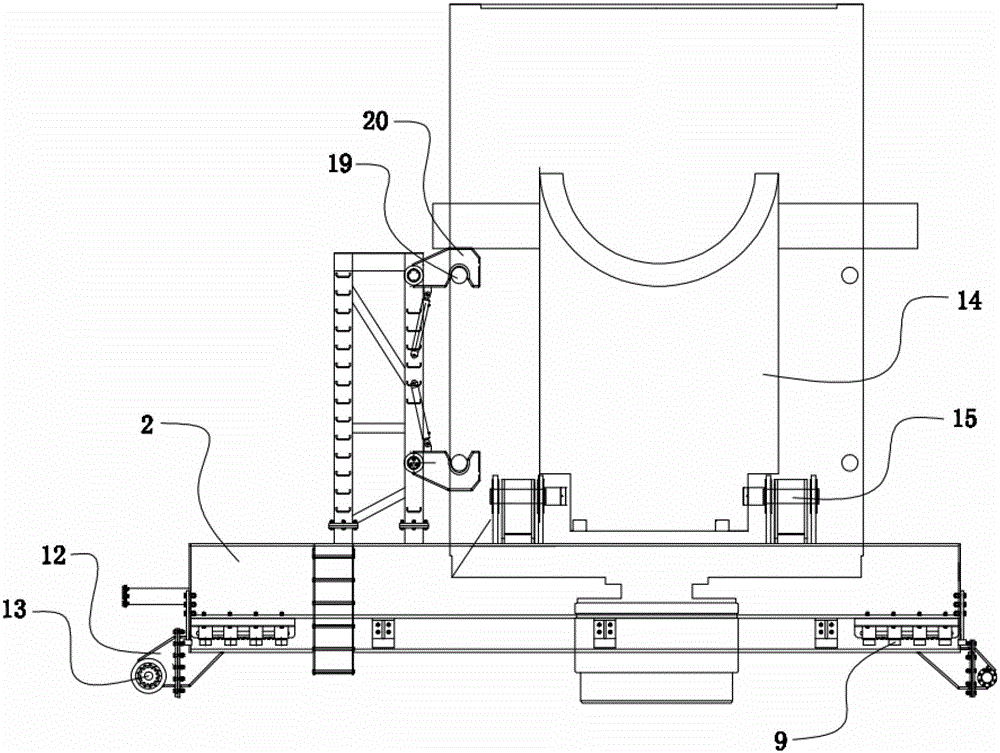

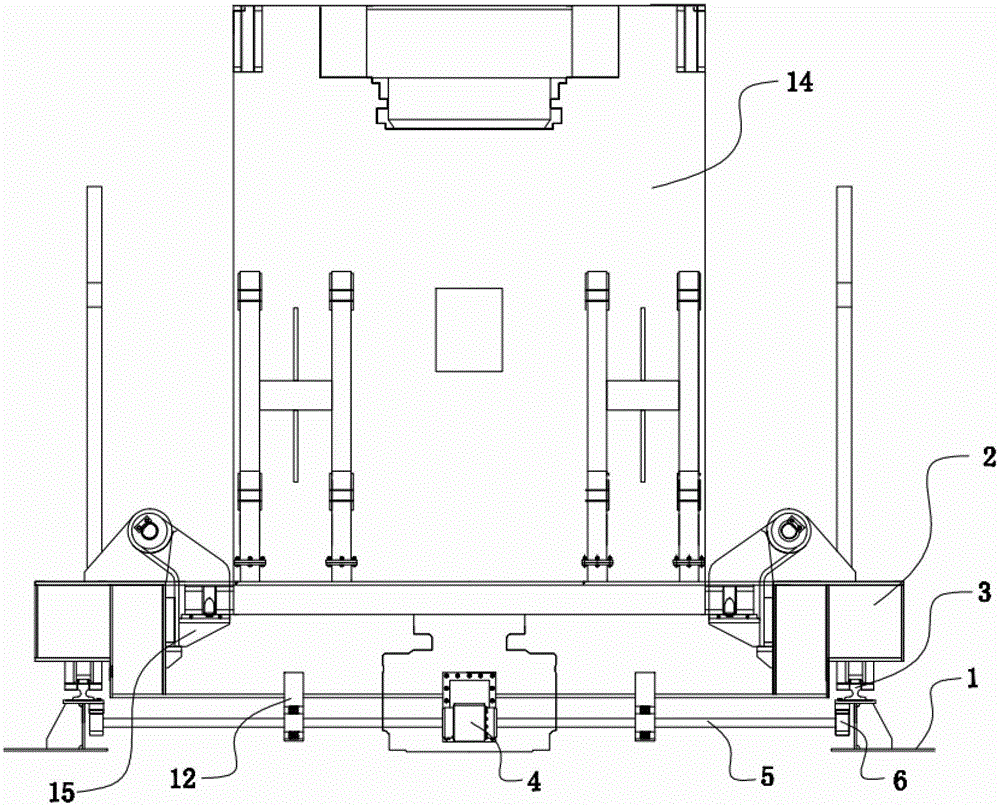

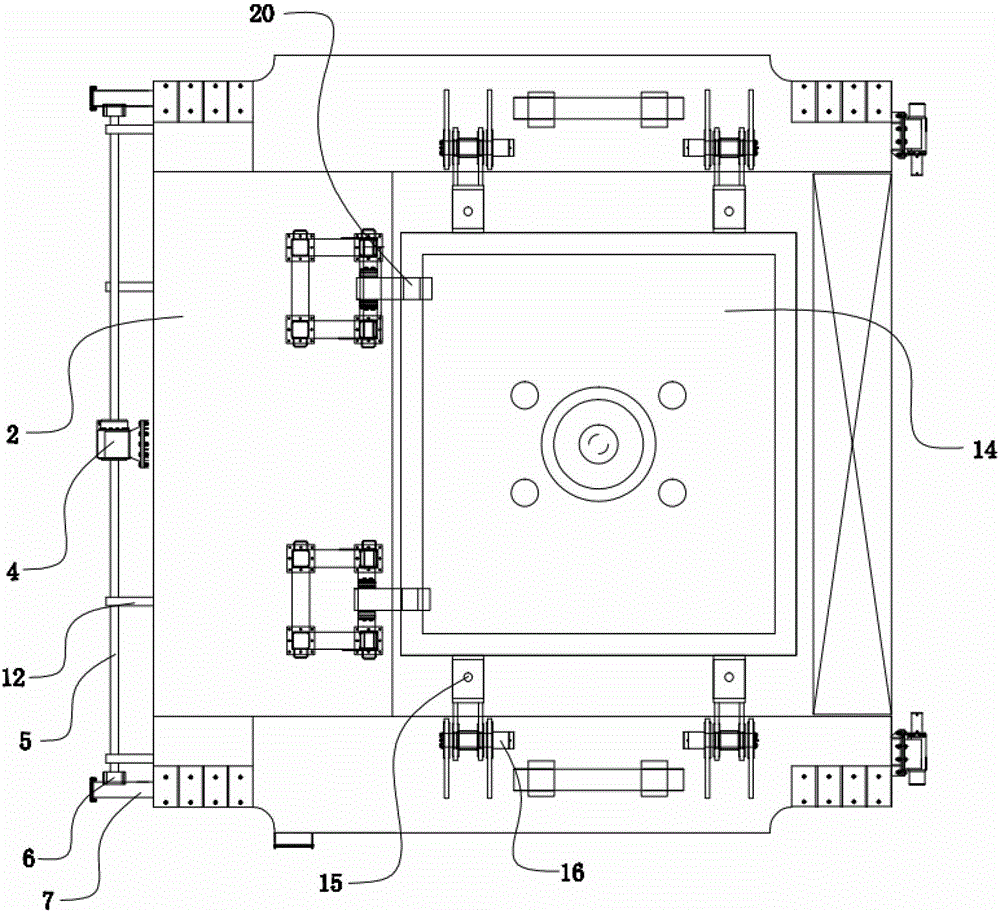

[0032] Such as Figure 1 to Figure 9 As shown, this embodiment is applicable to the BOP transfer device for deep-sea floating drilling, including a base 2 and a guide rail 3 arranged on the hull 1, the base 2 can move relative to the hull 1 along the guide rail 3, and the base 2 is provided with a drive motor 4. The driving shaft 5 of the driving motor 4 is provided with a driving gear 6, and the hull 1 is provided with a rack 7 parallel to the extending direction of the guide rail 3. The driving gear 6 and the rack 7 cooperate with each other, and the driving gear on the driving mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com