White edge detecting method for hot galvanizing alloying plate

A technology of alloying plates and detection methods, which is applied in the direction of testing metals, measuring devices, and material inspection products, and can solve problems such as setting and adjustment of alloying power, long transition time, and inability to trace white edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

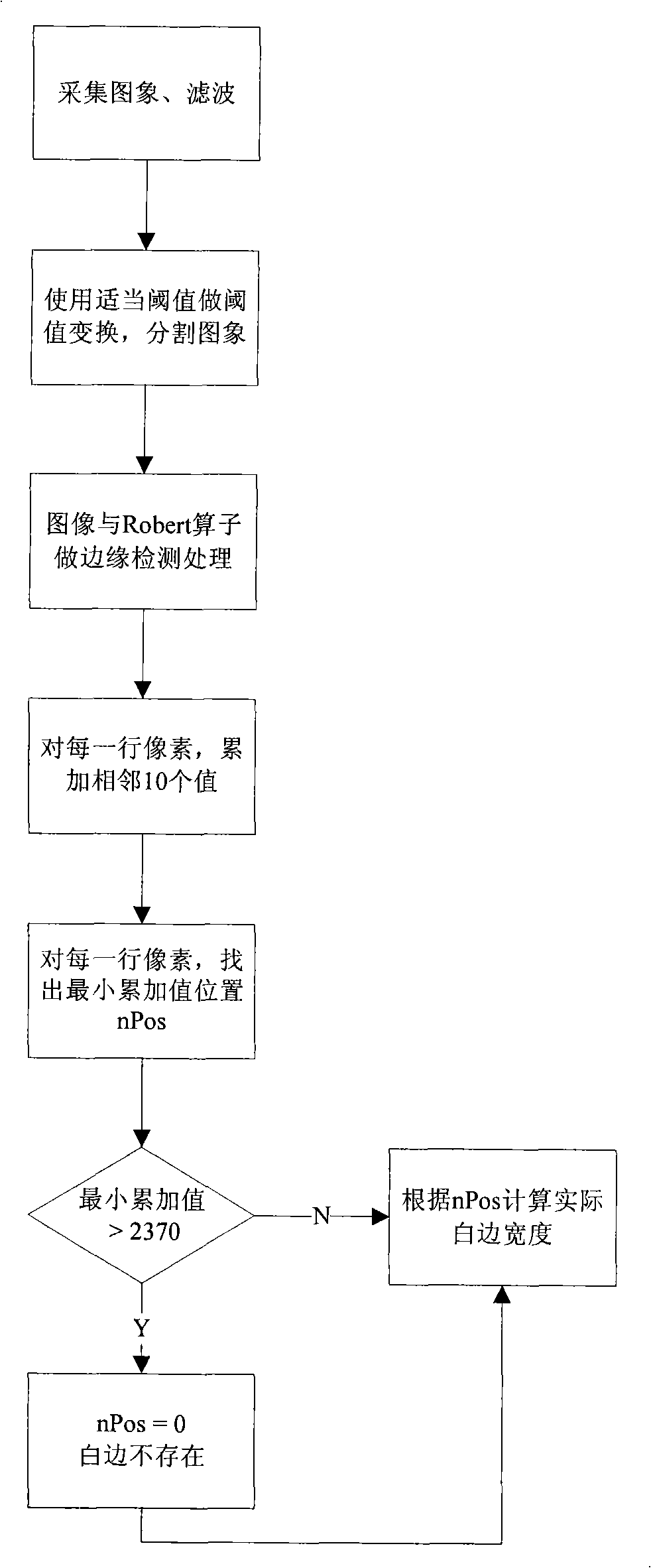

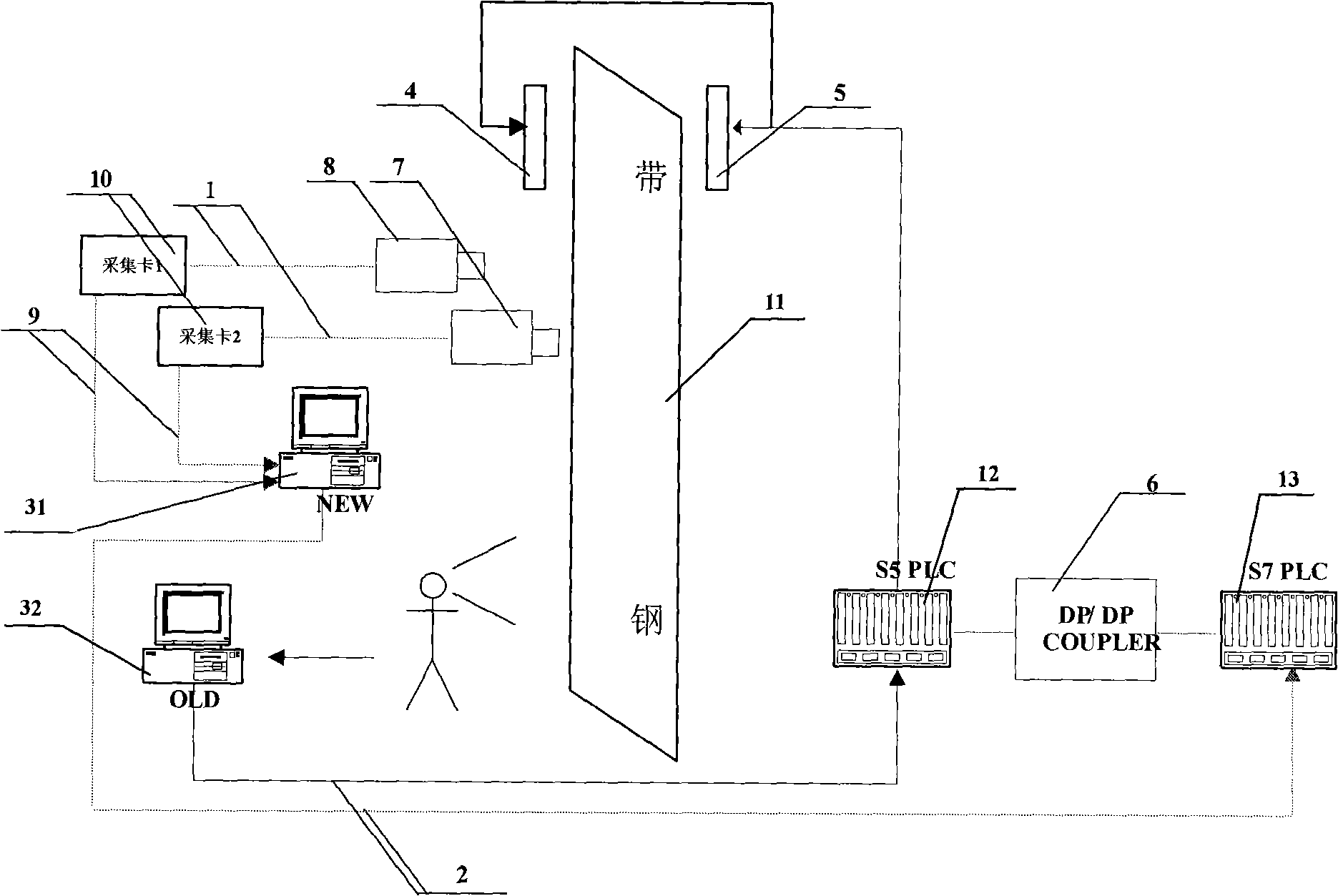

Method used

Image

Examples

Embodiment

[0093] 1. Get the image ( Image 6 ), to get the original image pixel value curve ( Figure 7 )

[0094] 2. Calculate the histogram H(D) of the image

[0095] H ( D ) = lim ΔD → 0 A ( D ) - A ( D + ΔD ) ΔD = - d dD A ( D ) - - - ( 1 )

[0096] The histogram describes the number of pixels with a certain gray value in the image. In formula (1), D represents the gray level, and A(D) repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com