Electric connector and manufacturing method thereof

A technology of an electrical connector and a manufacturing method, which is applied in the field of electrical connectors and its manufacturing, can solve the problems of complex production processes, immovable solder balls, scratches, etc., and achieve the effects of reducing production processes, simple processing, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The electrical connector of the present invention will be further described below in conjunction with the accompanying drawings.

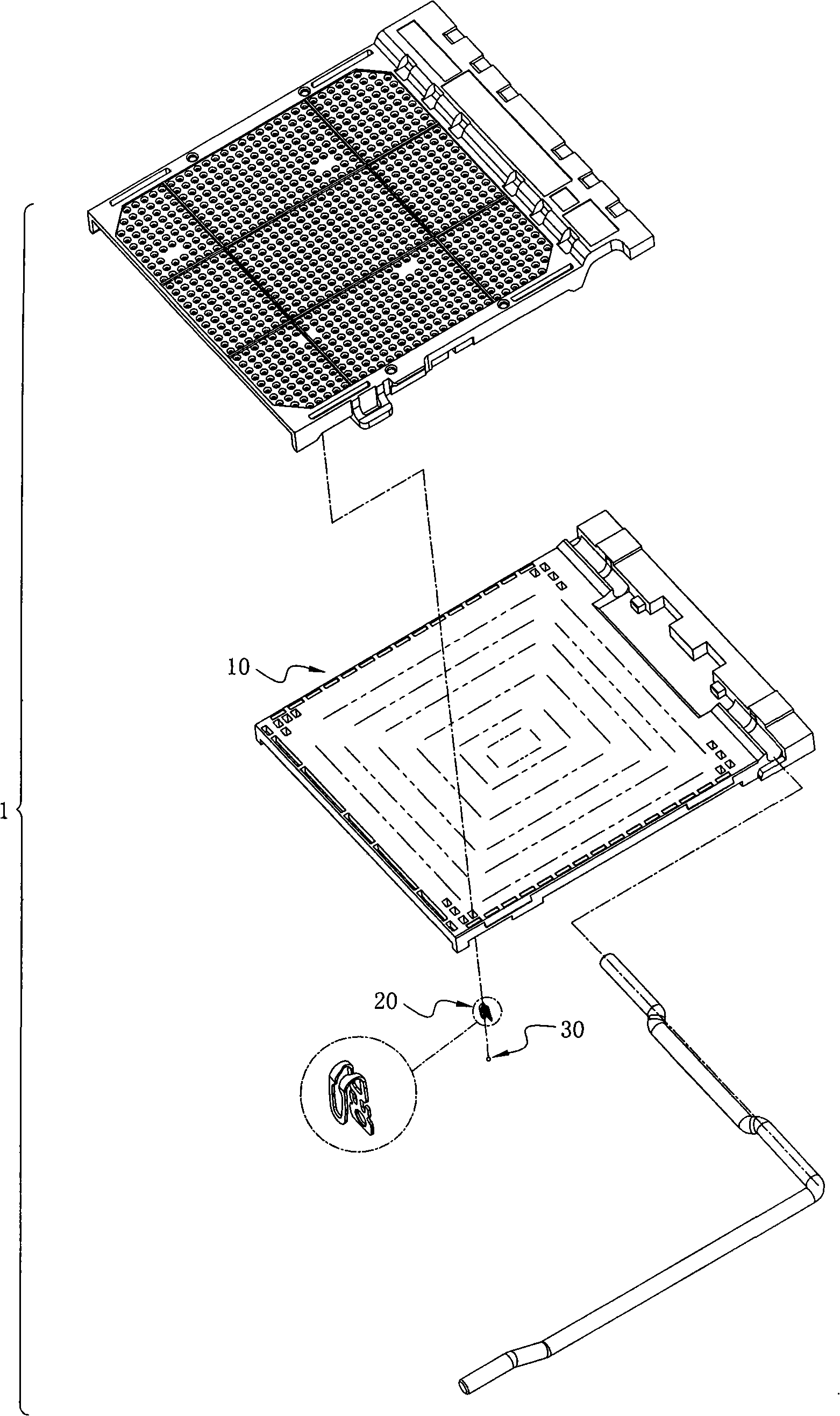

[0024] Electrical connector 1 of the present invention, see figure 1 , including an insulating body 10 , a plurality of conductive terminals 20 and solder balls 30 . Its lower end is connected with the circuit board 2, and the upper end is connected with the central processing unit 3, such as Figure 14 .

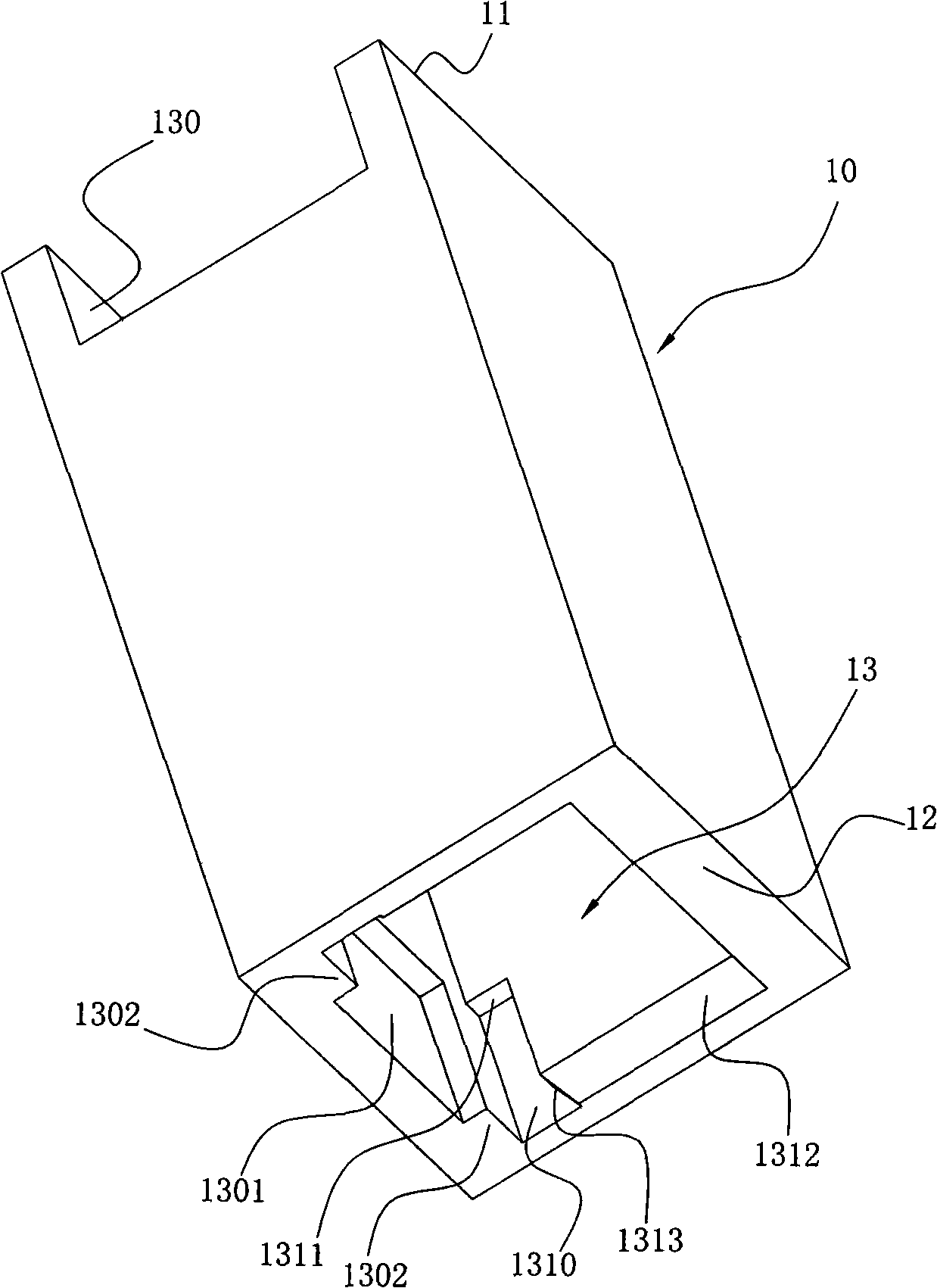

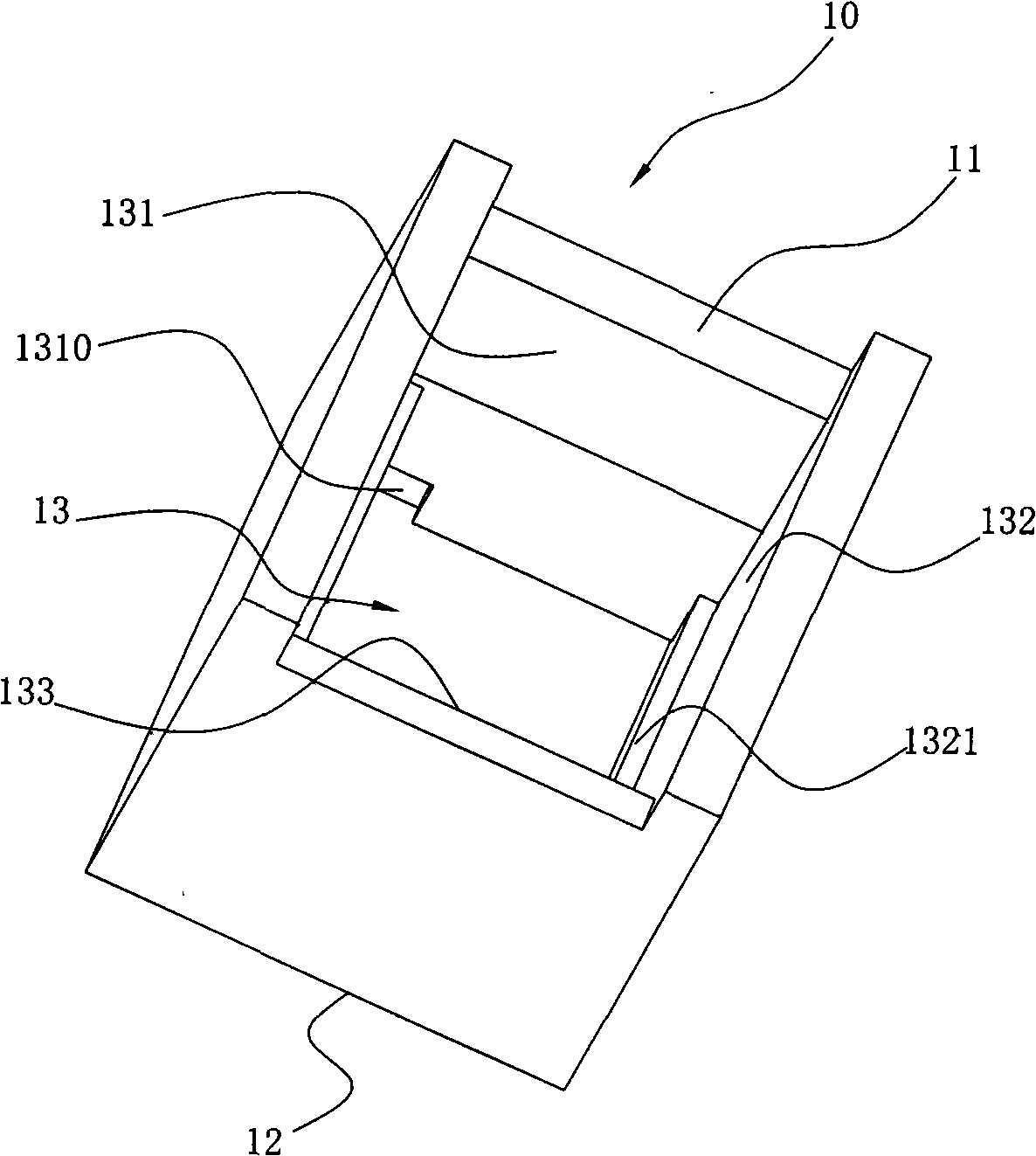

[0025] Please refer to Figure 2 to Figure 3 , the insulating body 10 is provided with an upper surface 11 and a lower surface 12, and a plurality of receiving holes 13 run through the upper and lower surfaces 11, 12 ( figure 2 , 3 Only one of them is drawn), the receiving hole 13 is provided with a first inner side wall 130, the third inner side wall 132 is opposite to the first inner side wall, and the other two inner side walls are respectively the second inner side wall 131 and the fourth inner side wall The walls 133 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com