pneumatic vibrator

A technology of pneumatic vibrator and exhaust hole, which is applied in the direction of fluid using vibration, etc., can solve the problems of vibrator vibration amplitude and vibration frequency reduction, contact surface wear, failure, etc., to achieve long service life, prolong service life, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

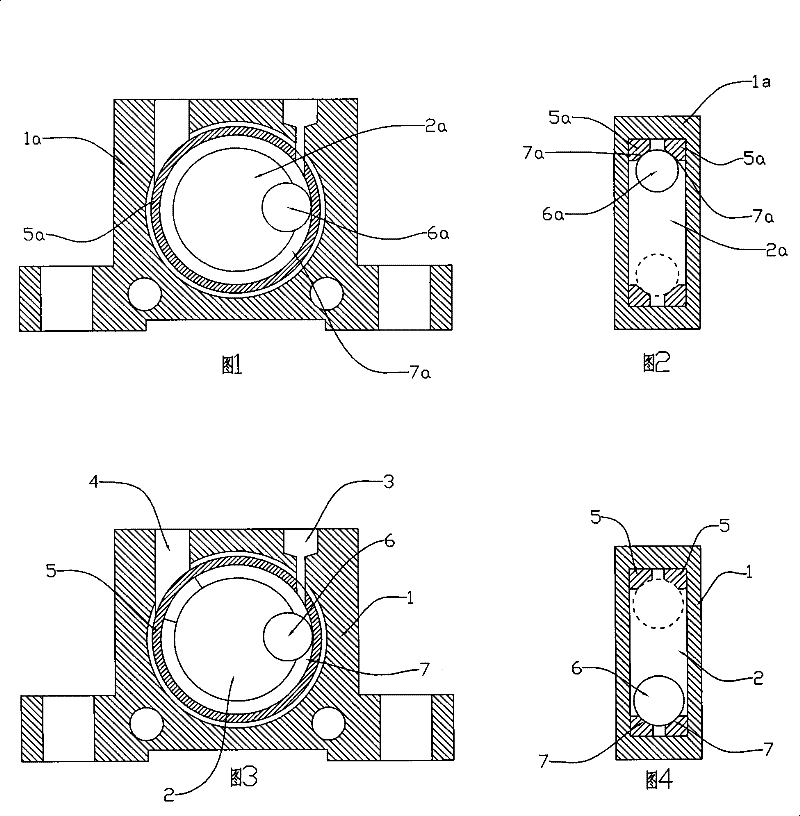

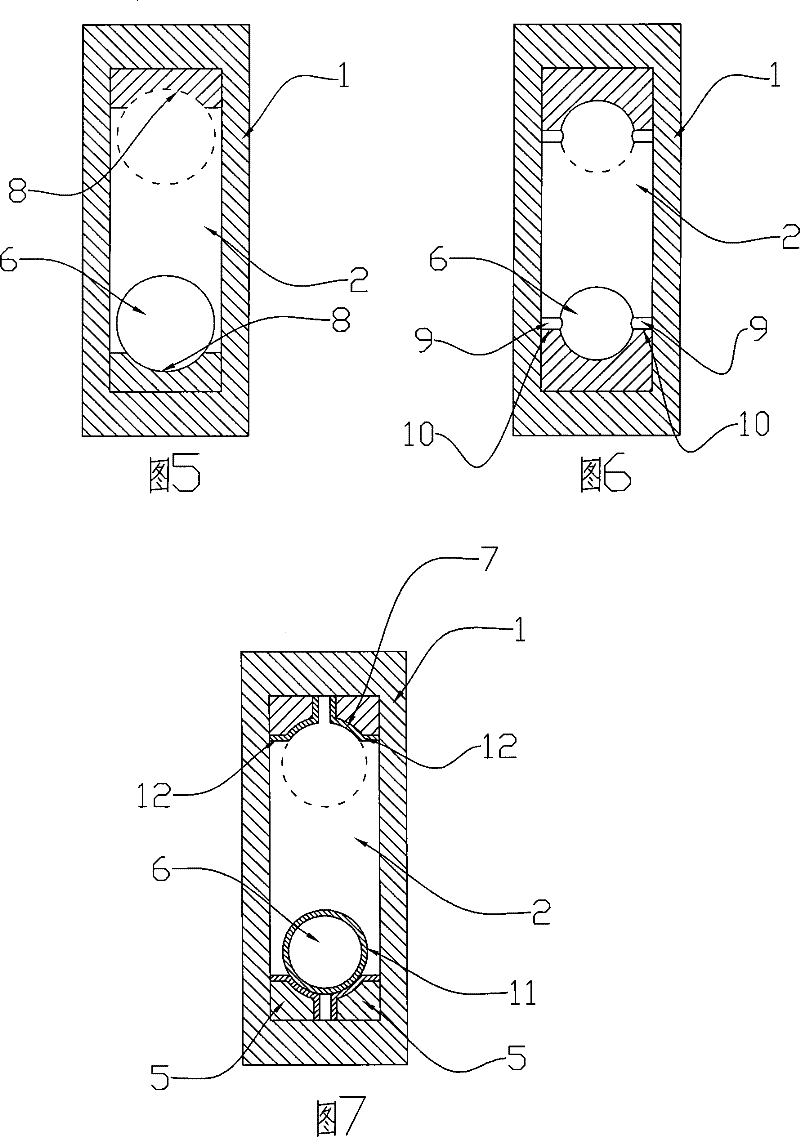

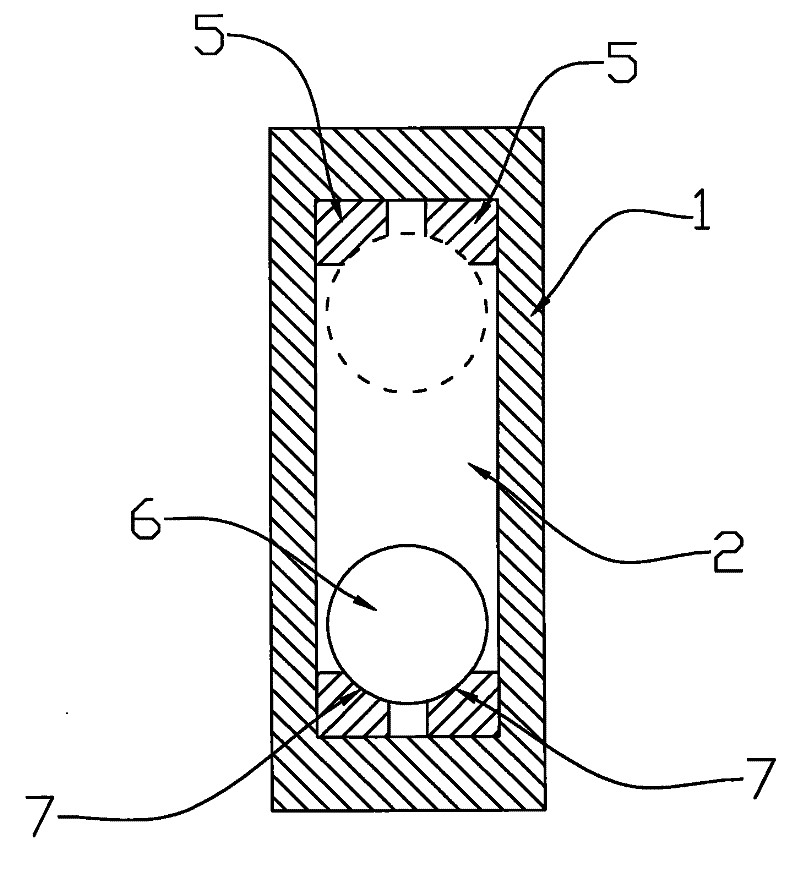

[0013] Example 1, such as image 3 , Figure 4 , a pneumatic vibrator has a housing 1, an air inlet 3 and an exhaust hole 4 communicating with the inner cavity 2 on the housing 1, two annular guide rails 5 are housed in the inner cavity of the housing, and two annular The opposite sides of the guide rails are bent downward to jointly form a track on which the ball 6 is mounted and can move along the track. The curvature of the curved surface 7 formed by the downward bending of the two circular guide rails matches the shape of the ball.

[0014] The curvature of the downward curved surface 7 on the opposite sides of the two circular guide rails 5 matches the shape of the ball 6. When the ball moves on the track formed by the two circular guide rails, it can completely fit the curved surfaces of the circular guide rails on both sides, increasing the aerodynamic force. The contact area between the vibrator ball and the track reduces the friction force and the pressure generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com