Mould mechanism capable of detecting extrusion traction on-line and extruder thereof

A technology of pultrusion mold and mold mechanism, which is applied in the field of thermoplastic molding mold mechanism and pultrusion machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

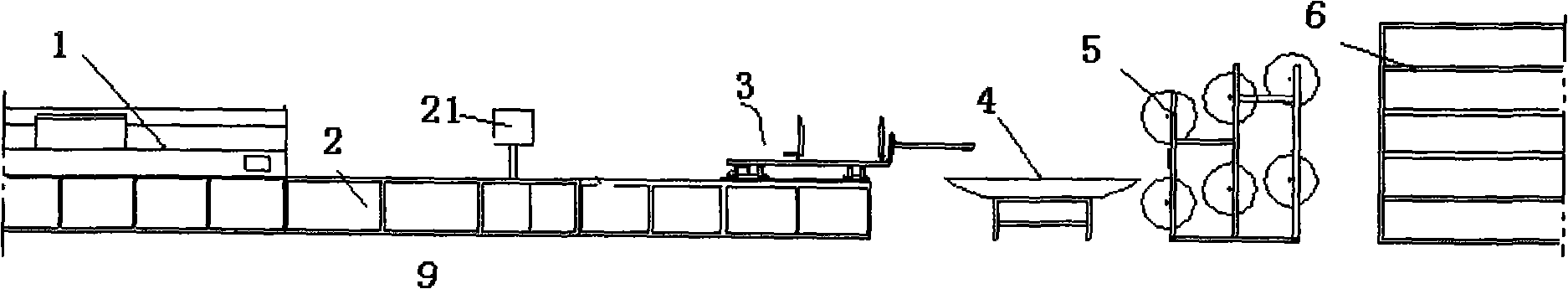

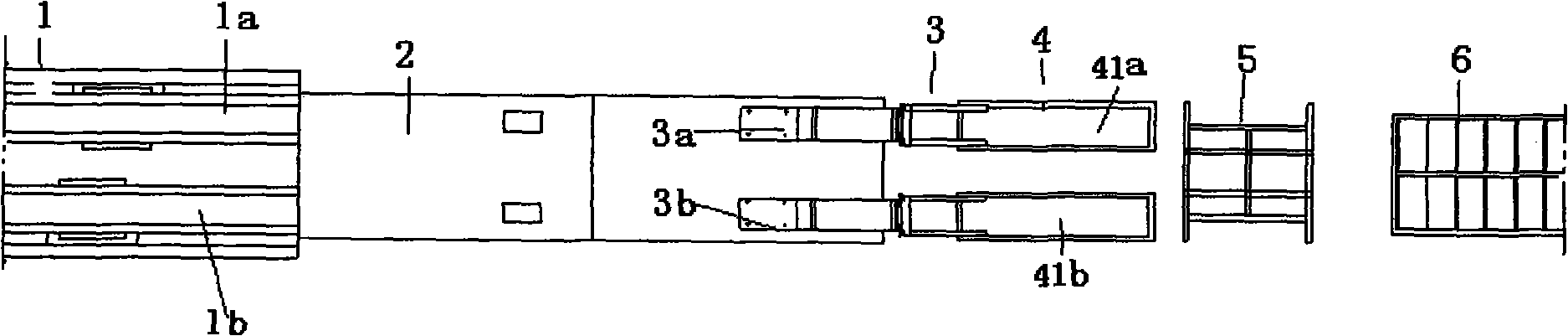

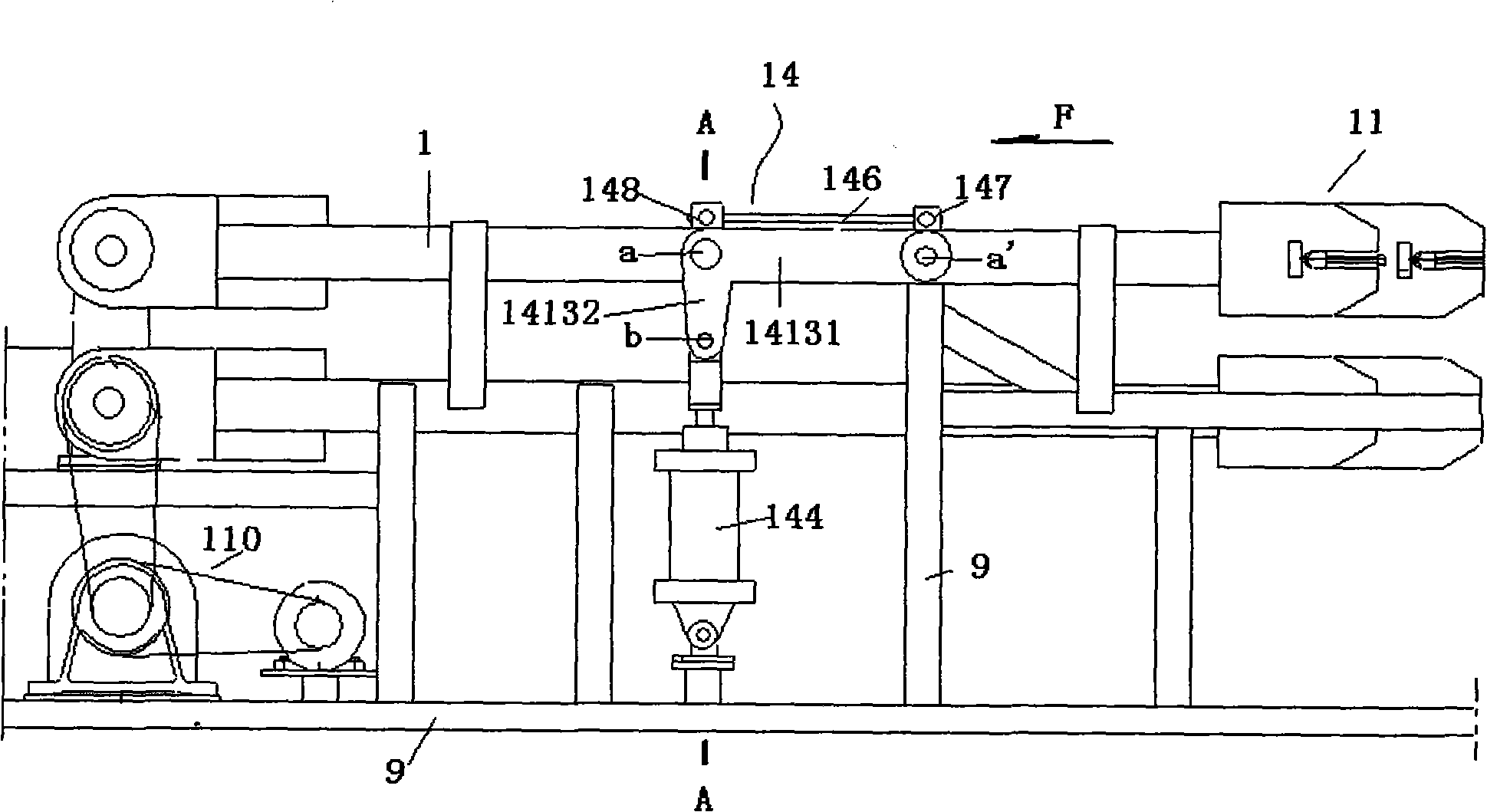

[0062] see figure 1 As shown in -7, the double-head pultrusion machine for composite materials includes a traction mechanism 1, an intermediate frame 2, a thermoplastic molding mold part 3, a dipping part 4, a felt feeding mechanism 5, and a yarn feeding mechanism 6, wherein, The traction mechanism 1 is composed of a first traction mechanism 1a and a second traction mechanism 1b respectively installed on the frame 9, and the first traction mechanism and the second traction mechanism are arranged at a preset distance before and after, so as to save floor space; The traction mechanism has the same structure, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com