Steel plate having superior pitting corrosion resistance and manufacturing method thereof

A steel plate, high-quality technology, applied in the field of steel plate with excellent pitting corrosion resistance, can solve the problems of not being able to apply continuous heating furnaces with excellent productivity and economical efficiency, and achieve the effect of excellent pitting corrosion resistance and excellent pitting corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

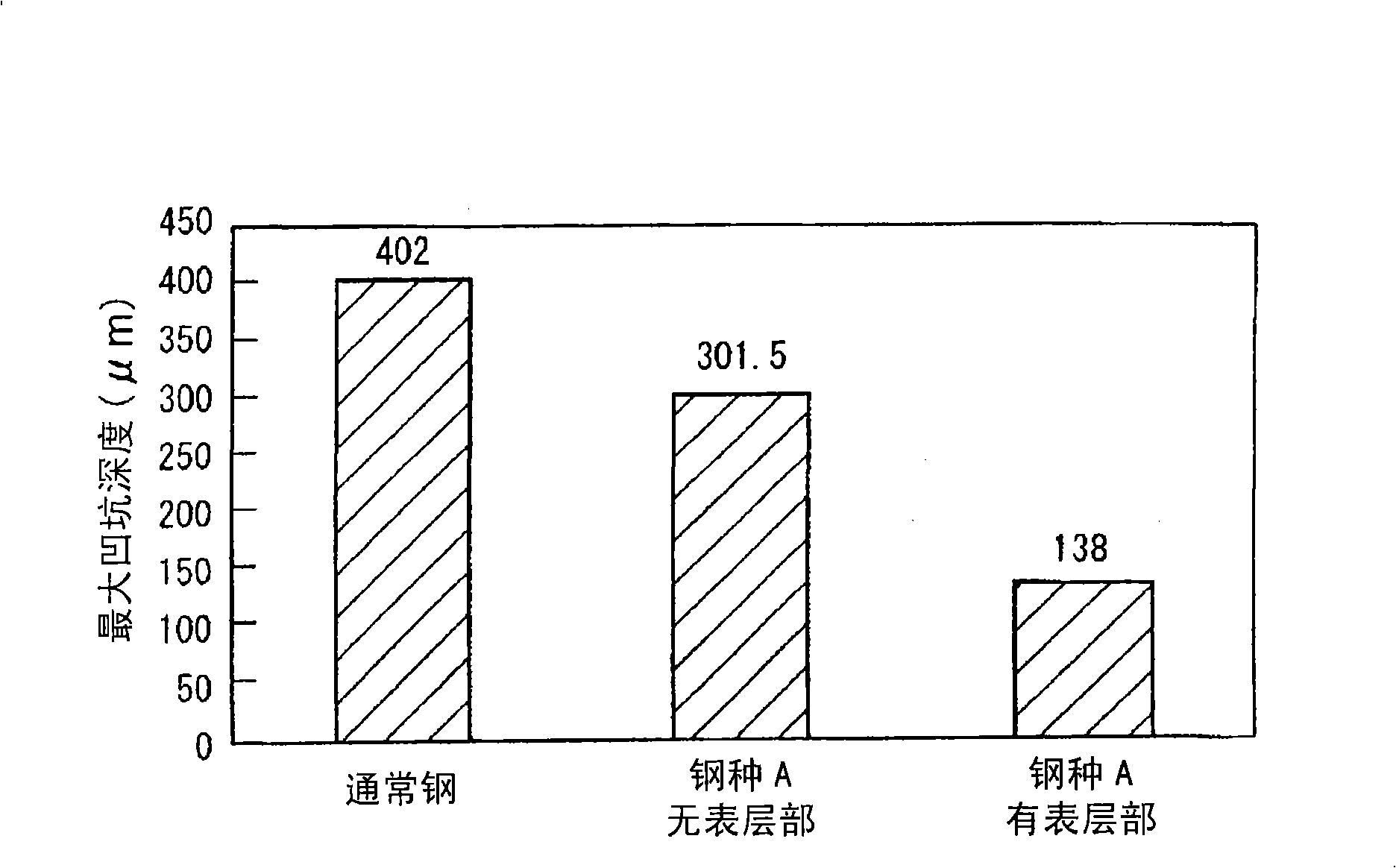

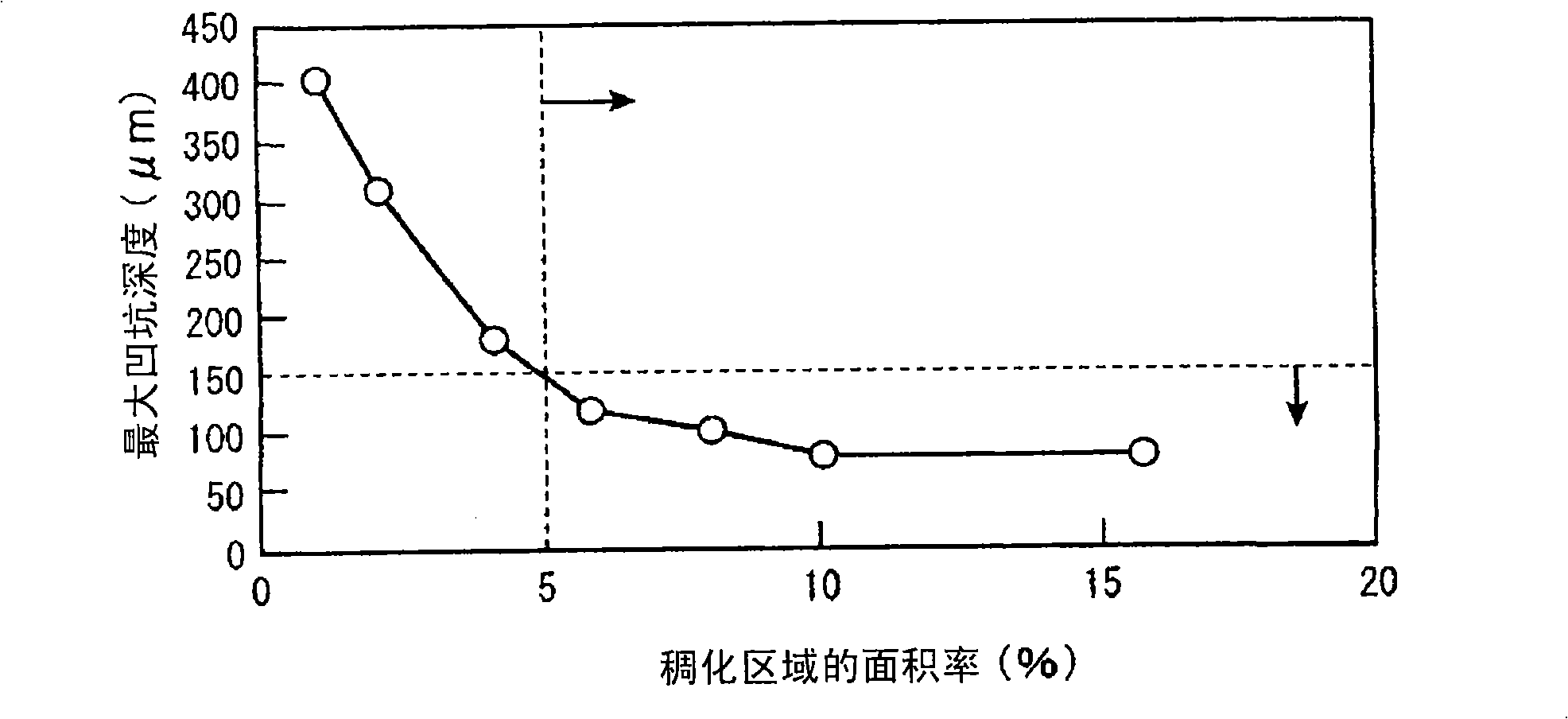

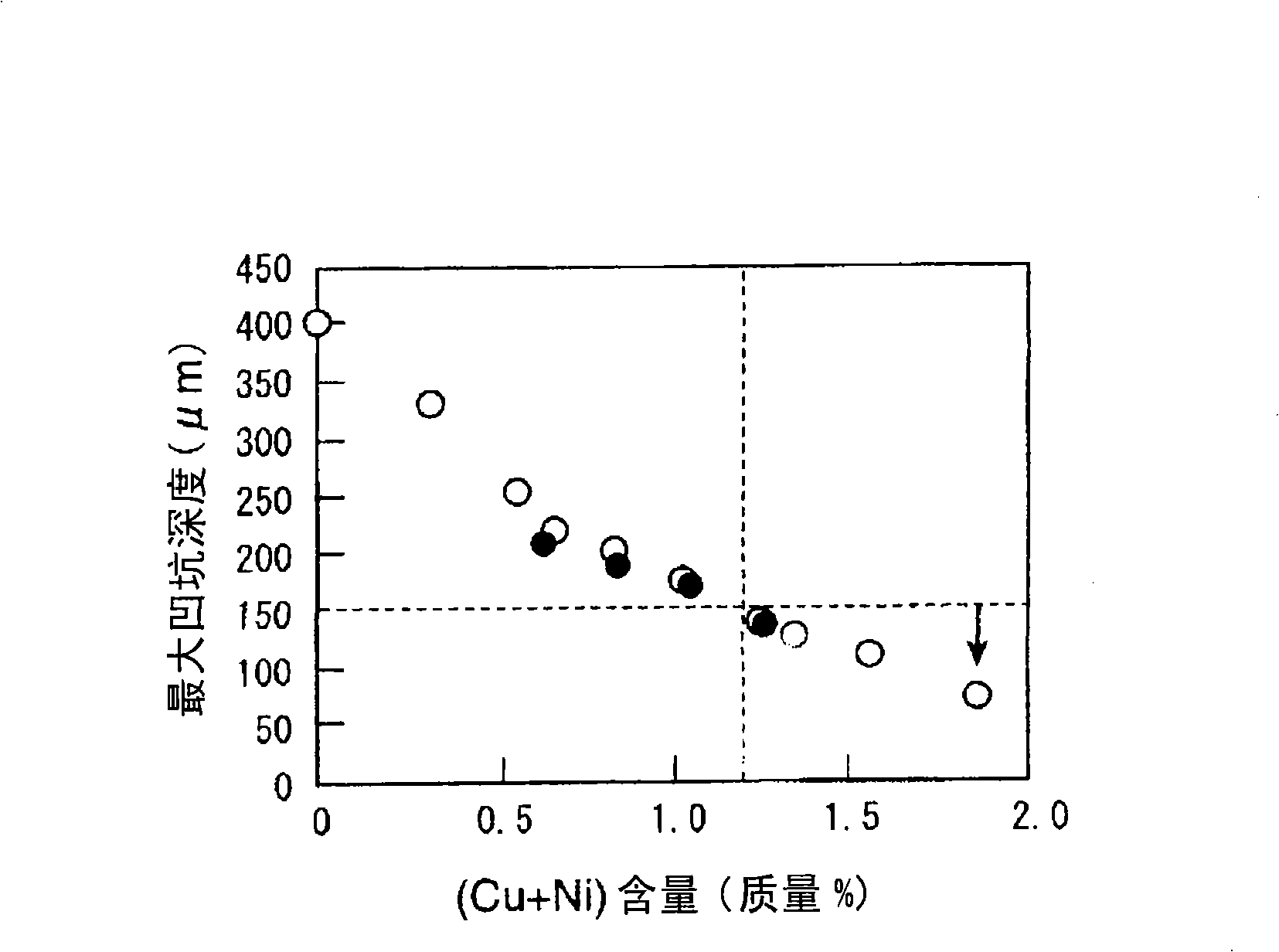

[0021] Cu and Ni are known to be effective elements for improving corrosion resistance, but when added in a large amount, not only the weldability is deteriorated, Ni is particularly expensive, but also the production cost is increased as a result. Under such circumstances, the present inventors have conducted studies from various angles with the aim of realizing a steel sheet excellent in corrosion resistance (especially pitting corrosion resistance).

[0022] As a result, they found that it is not necessary to contain a large amount of Cu and Ni in the steel sheet, but only the surface layer of the steel sheet should be enriched. In addition, it was found that as a method of enriching Cu and Ni on the surface of the steel sheet, if the appropriate temperature range and oxygen concentration during heating of the steel sheet are specified, the secondary scale formed during rolling can be formed in a very short time. Therefore, a region enriched in Cu and Ni (hereinafter referr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com