High-Cr ferrite stainless steel and manufacturing method thereof

A manufacturing method and ferritic technology, applied in the field of stainless steel, can solve the problems of difficult to avoid the sigma phase brittle temperature zone, difficult industrial production of high-chromium ferritic stainless steel, etc., achieve good room temperature toughness, excellent resistance to pitting corrosion, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

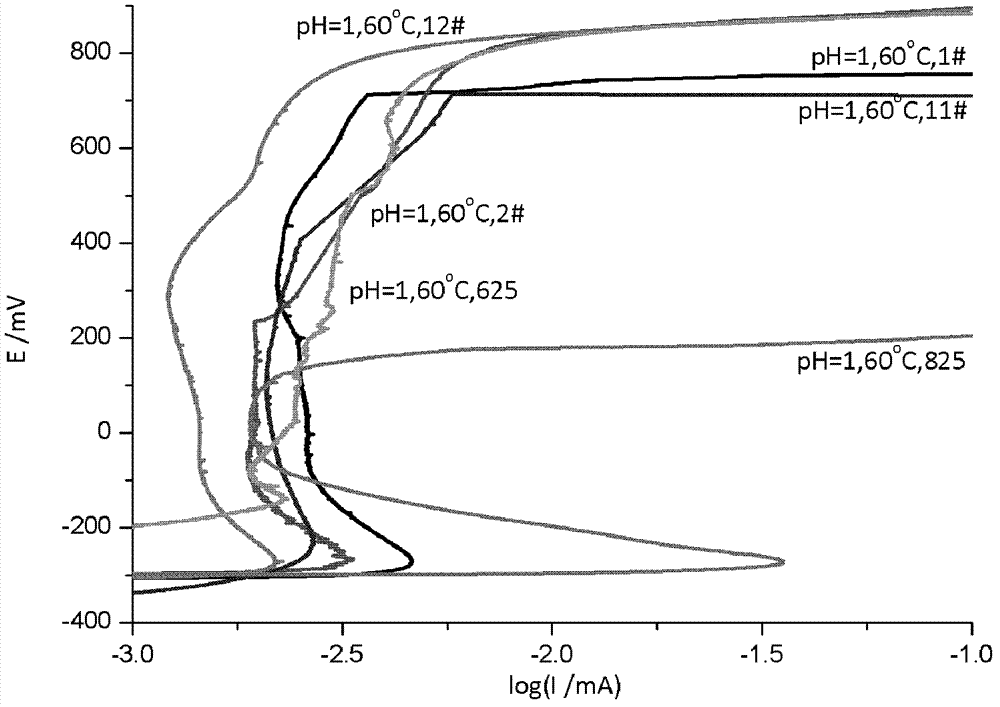

[0058] Example 1: Pitting corrosion resistance of high Cr ferritic stainless steel samples

[0059] According to the national standard GB4334.9-84, the pitting potential of four samples of high-Cr ferritic stainless steel and the comparison materials 625 and 825 corrosion-resistant alloys were tested by potentiodynamic method under different media conditions ( figure 1 ). The results show that the 2# and 12# samples with higher pitting equivalent (PRE) have the highest pitting potentials, which are equivalent to the comparison material 625 corrosion-resistant alloy, and the pitting potentials of 1# and 11# samples with lower pitting equivalents are relatively higher. Low, the pitting potential of the above five materials is much higher than that of the comparison material 825 corrosion-resistant alloy, indicating that high Cr and Mo content has a significant effect on improving pitting corrosion resistance.

Embodiment 2

[0060] Example 2: Critical Pitting Potential (CPT) of high-chromium ferritic stainless steel samples

[0061] Table 3 G48-C test results of 1#, 2#, 11# and 12# samples

[0062]

[0063] According to the ASTM-G48 method of the American Society for Testing and Materials, the critical pitting temperature of four samples of high-Cr ferritic stainless steel was tested. It can be seen from Table 3 that samples 1# and 11# with low Cr content failed to pass the test at 65°C. Serious macroscopic corrosion pits appeared on the surface of the samples, and the average corrosion rate was 3 times higher than that of the other two samples. ~4 orders of magnitude. After pickling and passivation treatment, although the corrosion rate has decreased, it is still 2 to 3 orders of magnitude higher than that of 2# and 12# samples. The 2# and 12# samples with higher Cr content not only passed the test at 65°C, but also had an average corrosion rate of only 10-2 after the test at 70°C, which ind...

Embodiment 3

[0064] Example 3: Crevice corrosion resistance of high Cr ferritic stainless steel samples

[0065] Table 4 Crevice corrosion test results of 44660 high-chromium ferritic stainless steel

[0066]

[0067]

[0068] According to the American Society for Testing and Materials standard ASTM-G48, the crevice corrosion performance of high-Cr ferritic stainless steel samples and comparison materials 625 and 825 alloys in different media was tested at a test temperature of 50 °C (Table 4). 6% FeCl in the absence of hydrochloric acid 3 After 72 hours of testing at 50°C in the solution, the weight loss of 1# and 11# samples exceeded the critical value of 1g, indicating that the two samples with low Cr content could not pass the test; while 2#, 12# and 625 alloys lost weight are very small, and the weight loss of the above three samples is much smaller than that of 825 alloy. Add 1% hydrochloric acid to a concentration of 6% FeCl 3 After 72 hours of testing at 50°C in the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com