Medium Cr ferrite stainless steel with ultra low content of C and N and manufacturing method thereof

A manufacturing method and a ferritic technology, applied in the field of stainless steel, can solve the problems of difficulty in avoiding the sigma phase brittle temperature zone, difficulties in industrial production of ferritic stainless steel, etc., and achieve good room temperature toughness, excellent resistance to pitting corrosion, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1: Pitting corrosion resistance of medium-Cr ferritic stainless steel samples with ultra-low C and N content

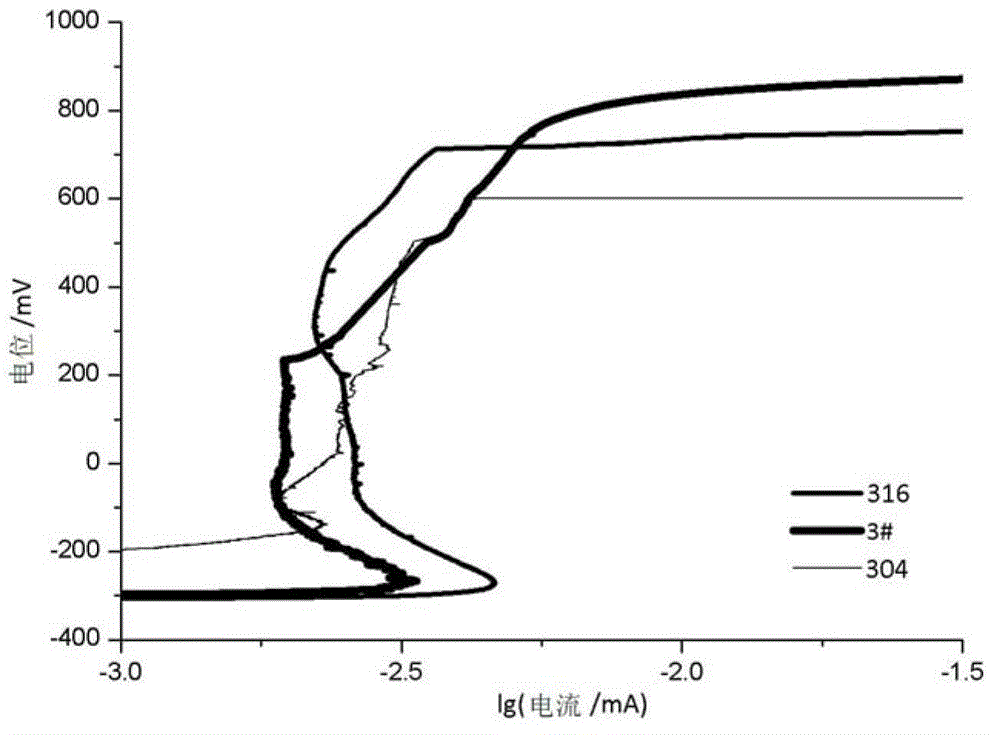

[0062] The pitting potential of the medium-Cr ferritic stainless steel 3# sample with ultra-low C and N content and the comparison materials 316 and 304 austenitic stainless steel were tested by potentiodynamic method according to the national standard GB4334.9-84 ( figure 1 ). The results show that the 3# sample (Table 3) with higher pitting equivalent (PRE) has the highest pitting potential, about 832mV, about 200mV higher than 304 austenitic stainless steel, and about 100mV higher than 316 austenitic stainless steel, indicating that Mo element The increase of the content has a significant effect on improving the pitting corrosion resistance.

[0063] Table 3 Differences in main components and pitting equivalents between medium-Cr ferritic stainless steel with ultra-low C and N content and 304 / 316 stainless steel

[0064]

Embodiment 2

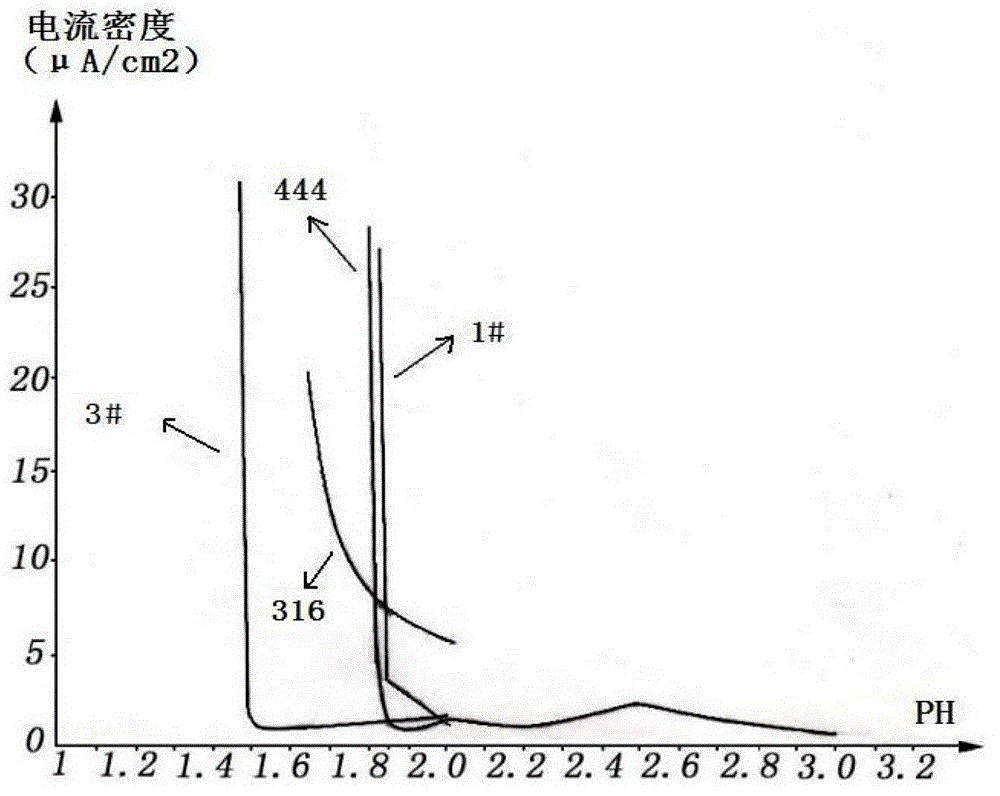

[0065] Example 2: Depassivation acidity (Depassivation pH, pH d )

[0066] According to the ASTM-G48 method of the American Society for Testing and Materials, the medium-Cr ferritic stainless steel 1# and 3# samples with ultra-low C and N content and the comparison materials 444 ferritic stainless steel and 316 austenitic stainless steel were removed. Passivation acidity test ( figure 2 ). The depassivation acidity value is a measured value, and its meaning refers to the ability of the material to resist the occurrence and expansion of crevice corrosion by electrochemical methods. The lower the value, the stronger the crevice corrosion resistance. It can be seen from Table 4 that the pHd value of the 1# sample with a Mo content of 1.12% is 1.83, and the pH of the 3# sample with a Mo content of 1.97% d The value reached 1.47, much smaller than the two comparative materials 316 austenitic stainless steel and 444 ferritic stainless steel, indicating that only when the acidity...

Embodiment 3

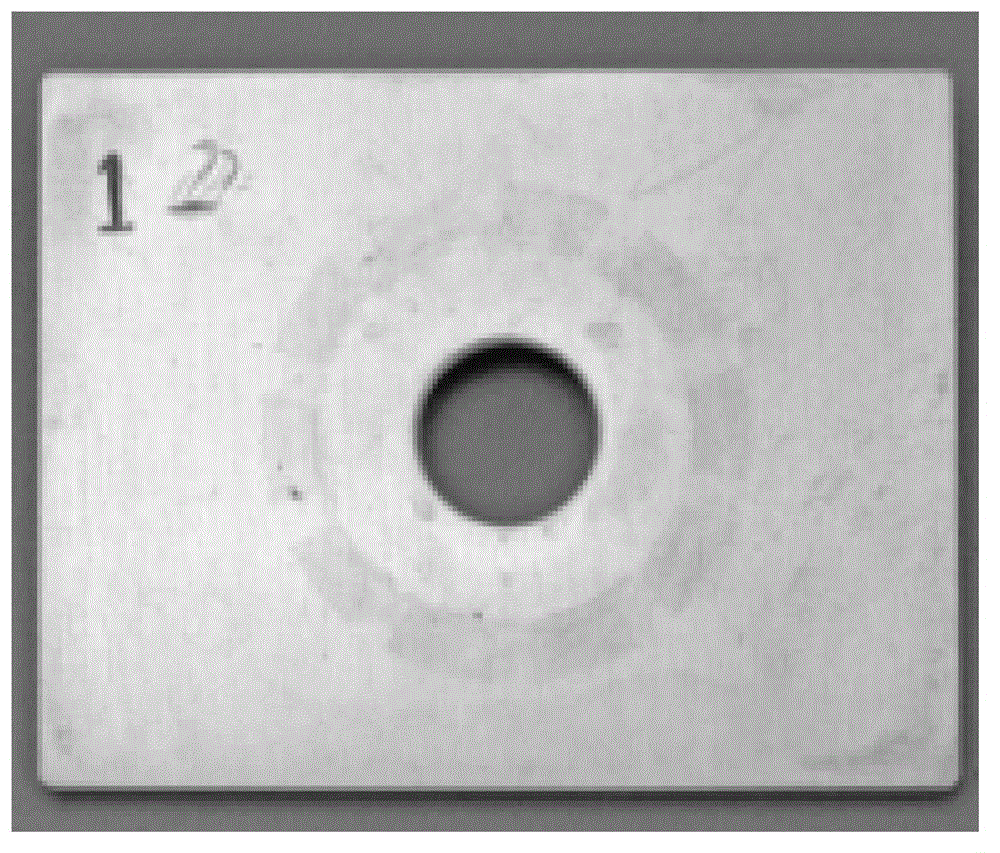

[0069] Example 3: Crevice corrosion resistance of medium-Cr ferritic stainless steel samples with ultra-low C and N content

[0070] According to the ASTM-G48 method of the American Society for Testing and Materials, the 3# sample of medium Cr ferritic stainless steel with ultra-low C and N content and the comparison materials 304 austenitic stainless steel and 316 austenitic stainless steel were tested in different media. Corrosion performance ( Figure 3-5 ). The test results show that the weight loss of 304 austenitic stainless steel has reached 1.9845g, far exceeding the critical value of 1g for judging the occurrence of crevice corrosion, and Figure 5 It shows that there are many obvious crevice corrosion pits on the surface of the sample; although 316 austenitic stainless steel does not produce obvious corrosion pits after the test, its weight loss is still as high as 1.6548g. In contrast, the Cr ferritic stainless steel 3# sample with a Mo content of 1.97% and an ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com