A large-diameter s31254 super austenitic stainless steel seamless pipe and its preparation process

A technology for the preparation of austenitic stainless steel, applied in the field of austenitic stainless steel, can solve the problems of reduced pressure resistance, low reliability and service life, and limited corrosion resistance of alloys, and achieve the effect of simple equipment and simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

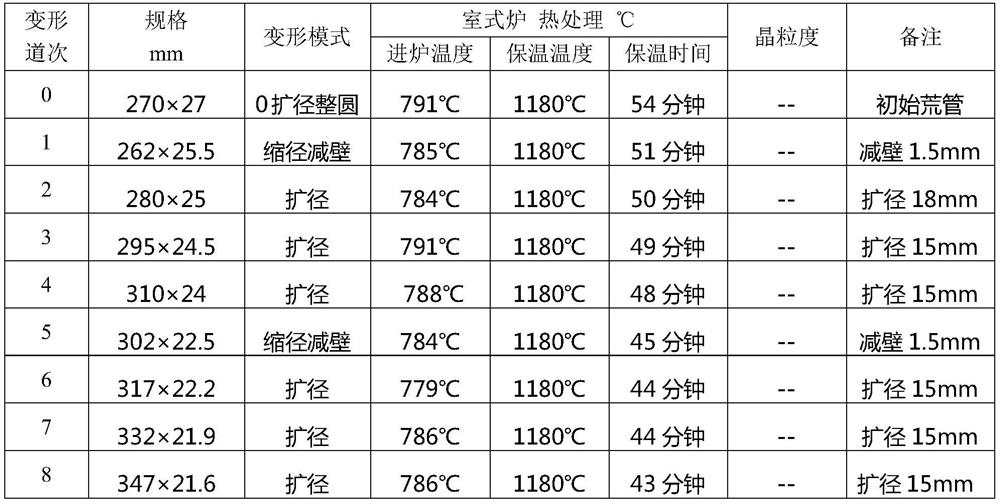

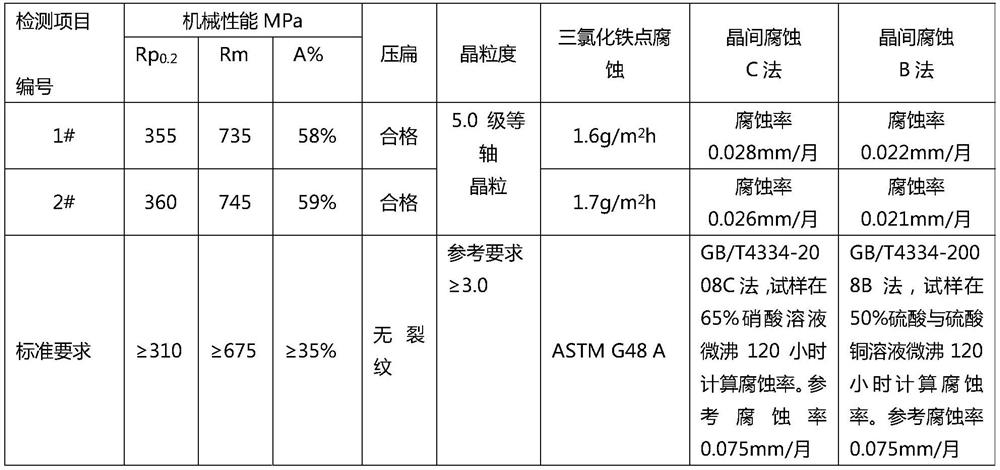

[0034] Example 1 Preparation of φ325×17mm S31254 Super Austenitic Stainless Steel Finished Pipe

[0035] The outer diameter of the round tube billet is φ240mm, and the blank tube is φ270×27mm after thermal perforation. First, heat treatment is performed to make the internal structure of the material uniform, the carbide is fully dissolved, and the grain size of the inner and outer walls tends to be uniform; the first time Drawing expansion deformation (1 cold drawing for wall reduction and diameter reduction, 3 consecutive diameter expansion cold drawing), the second drawing and expansion deformation (1 wall reduction and diameter reduction cold drawing, 3 consecutive diameter expansion cold drawing), and then for 3 consecutive times The finished large-diameter S31254 super austenitic stainless steel seamless pipe is obtained by wall-reducing cold drawing and heat treatment in one pass;

[0036] After each cold drawing, the tube blank is heat treated, and after each heat treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com