Modularization equipment and method for connecting principal and subordinate module thereof

A modular, module interface technology, applied in digital transmission systems, electrical components, transmission systems, etc., can solve the problems of high-level compatibility and limited portability of master-slave modules, shorten product development cycle, improve Portability, the effect of saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

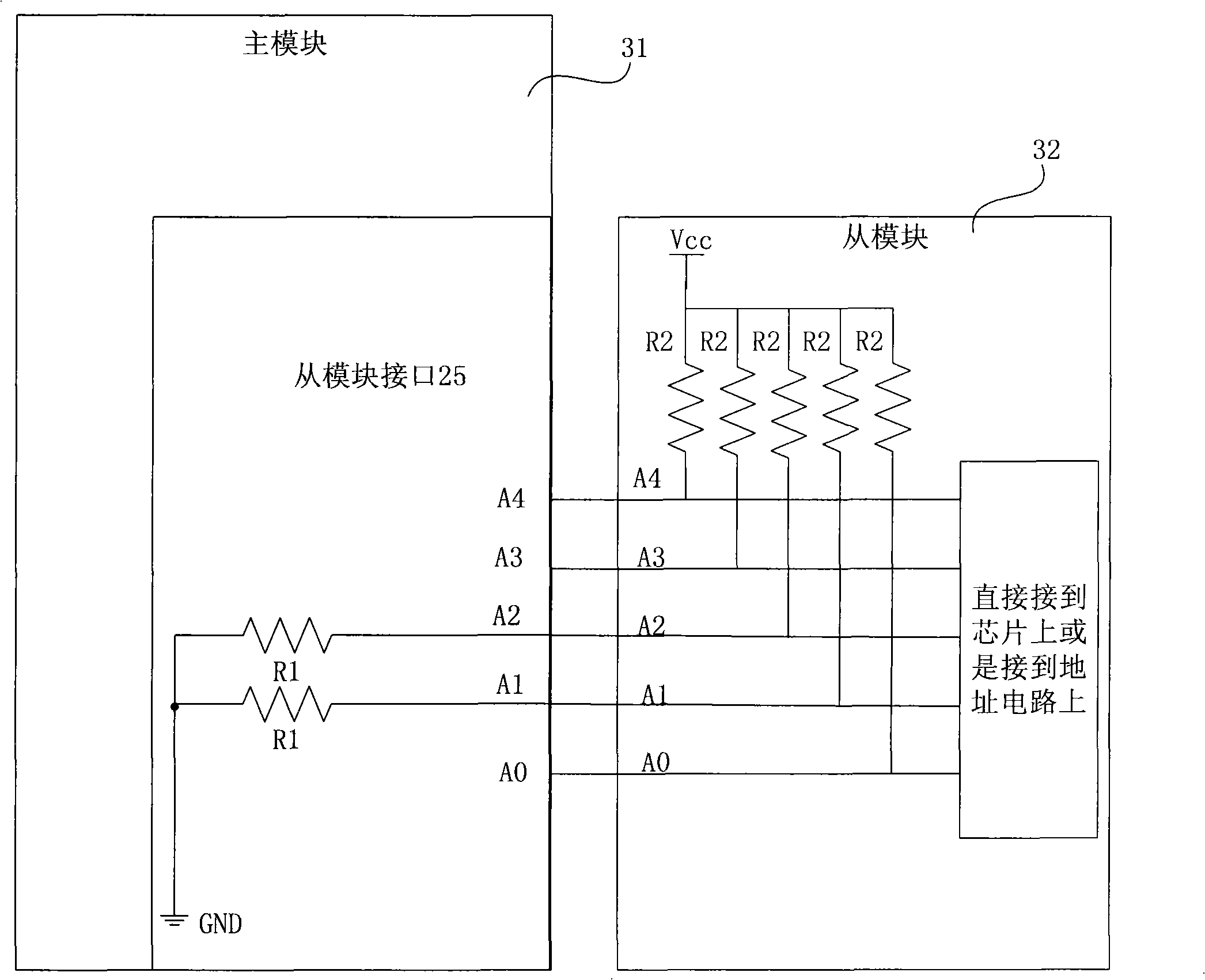

[0022] image 3 It is a structural schematic diagram of an embodiment of a modular device of the present invention. The modular device includes a master module 31 and a slave module 32. The address line of the slave module interface of the master module 31 that requires a low-level signal is grounded through a resistor. Taking the slave module interface 25 in the main module 31 as an example, since its address is 25, that is, "11001", its address line A1 and address line A2 need a low-level signal, so its address line A1 and address line A2 are both Connect to the low level GND through the resistor R1; all address lines of the slave module interface of the slave module 32 are connected to the high level Vcc through the resistor R2. The resistance value of the grounding resistance, that is, the resistance R2 may be 10Ω˜500Ω. In this embodiment, the resistance value of the resistance R1 is 100Ω, which strongly pulls up the signals in the address line A1 and the address line A2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com