Funeral monument image and manufacture method thereof

A production method and technology for tombstones, applied in tombs, monuments, mirrors, etc., can solve problems such as easy breakage, loss of shadow, and lack of good protection, and achieve the effect of not being afraid of rain and sand erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

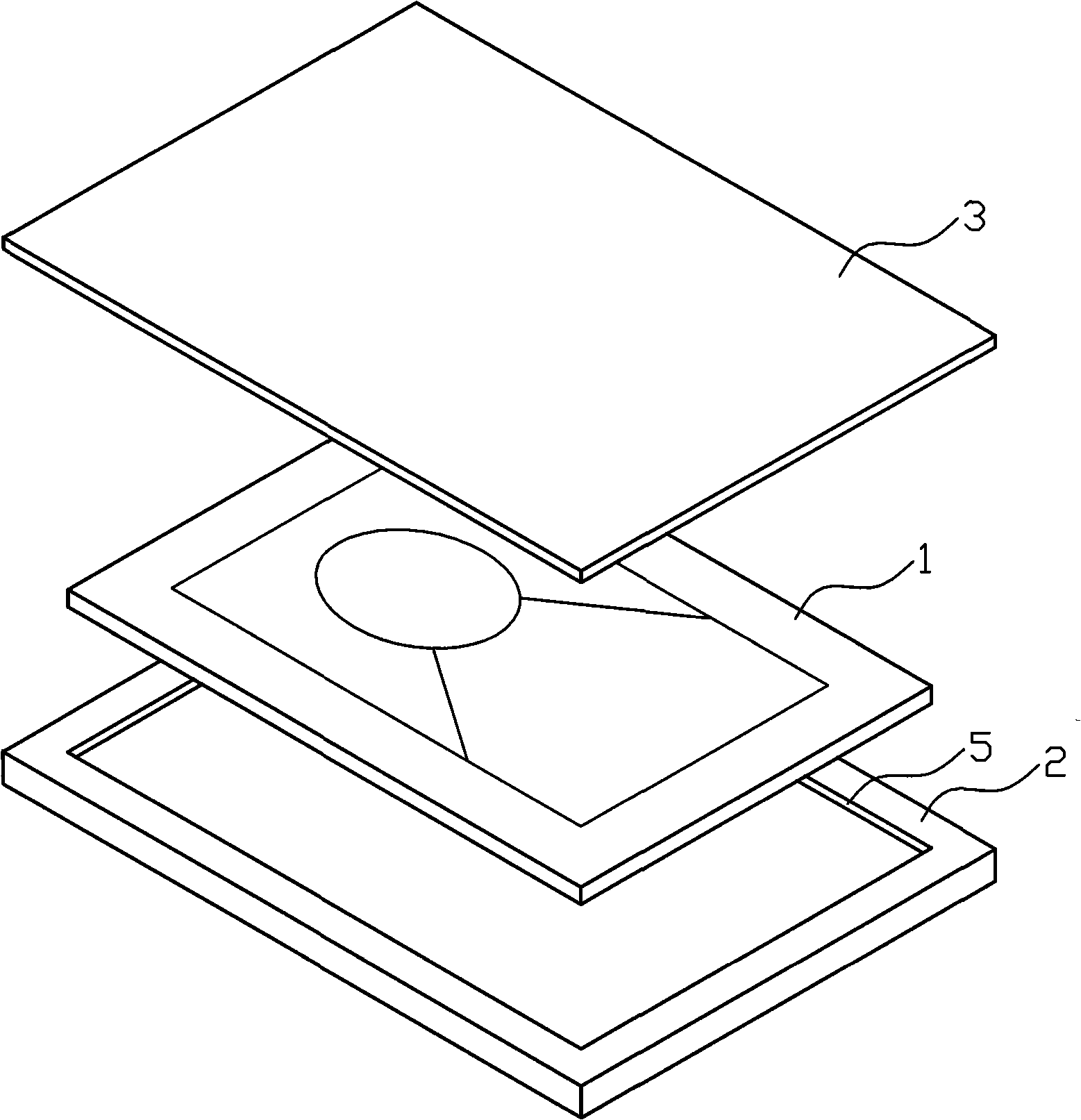

[0009] Such as figure 1 As shown, the tombstone image of this embodiment includes an imaging plate 1, a bottom plate 2, and a transparent top plate 3. The bottom plate 2 and the transparent top plate 3 are both made of acrylic plates, and the top surface of the bottom plate 2 is engraved with a groove 5 corresponding to the shape of the imaging plate. The imaging plate 1 is embedded in the groove 5, and the transparent top plate 3 is glued on the upper surface of the bottom plate 2 and the imaging plate 1.

[0010] How to make the tombstone statue:

[0011] a. First, image the processed portrait on the imaging plate 1;

[0012] b. Inlay the processed imaging plate 1 in the groove 5 of the bottom plate 2;

[0013] c. Carry out a fully enclosed treatment, apply shadowless glue on the surface around the groove 5 of the bottom plate, then cover the transparent top plate 3, and cure it with ultraviolet rays;

[0014] d. Polish the four sides of the molded product.

Embodiment approach 2

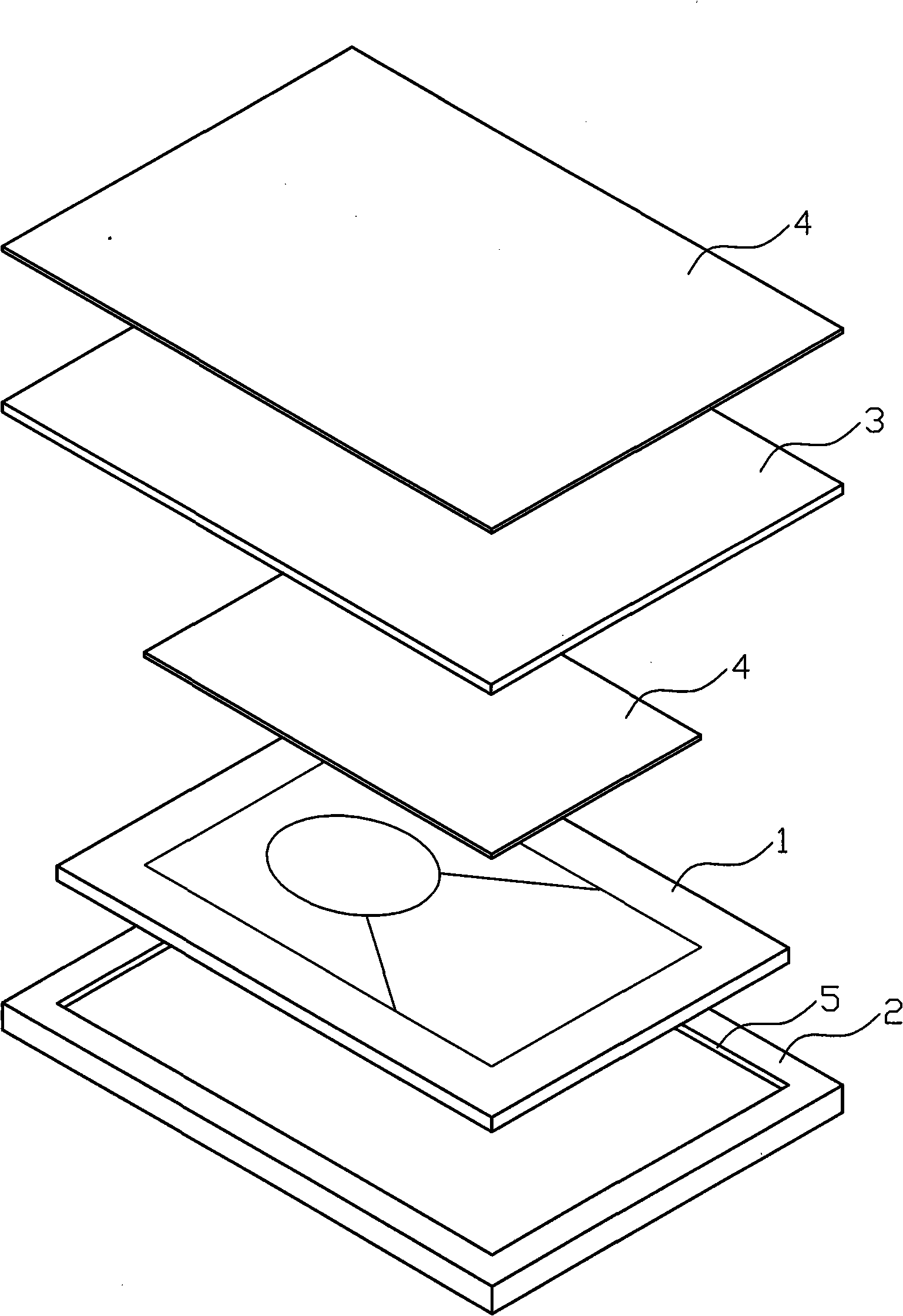

[0016] The difference from the first embodiment is that an anti-ultraviolet film 4 is pasted between the imaging plate 1 and the transparent top plate 3.

[0017] Production Method:

[0018] The anti-ultraviolet film 4 is directly attached to the upper surface of the imaging plate 1 after the step a of the manufacturing method of the embodiment 1, and the film and the imaging plate 1 are closely and seamlessly combined to achieve the purpose of vacuum. The rest of the steps are the same as in the first embodiment.

Embodiment approach 3

[0020] Such as figure 2 As shown, the difference from Embodiments 1 and 2 is that an anti-ultraviolet film 4 is pasted on the upper surface of the transparent top plate 3.

[0021] Production Method:

[0022] On the basis of the manufacturing method of Embodiment 1 or 2, after the tombstone image is fully enclosed, the UV-proof film 4 is directly pasted on the upper surface of the transparent top plate 3 to make it closely and seamlessly combined, and then polished.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com