On-line method for setting mechanism model-based plate parameter of double UCM temper milling machine group

A mechanism model and setting method technology, applied in digital control, contour control, instrument, etc., can solve problems such as large fluctuations in product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

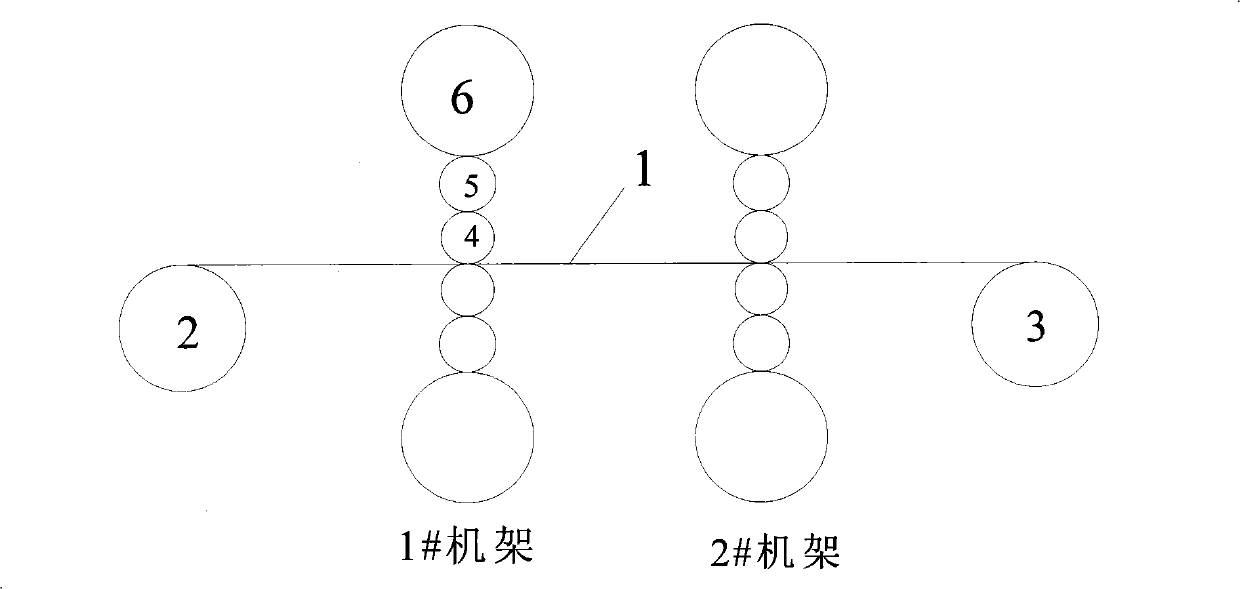

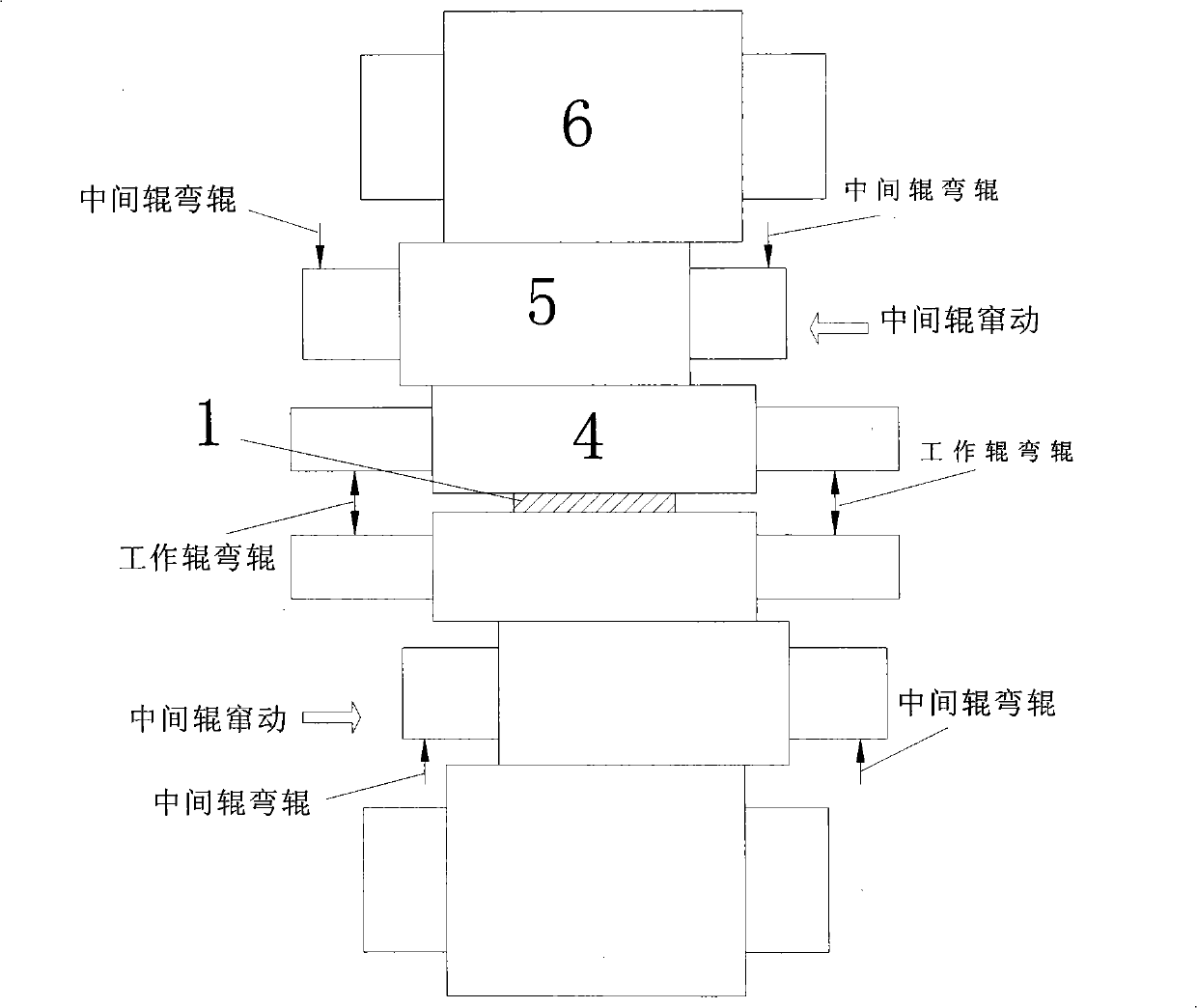

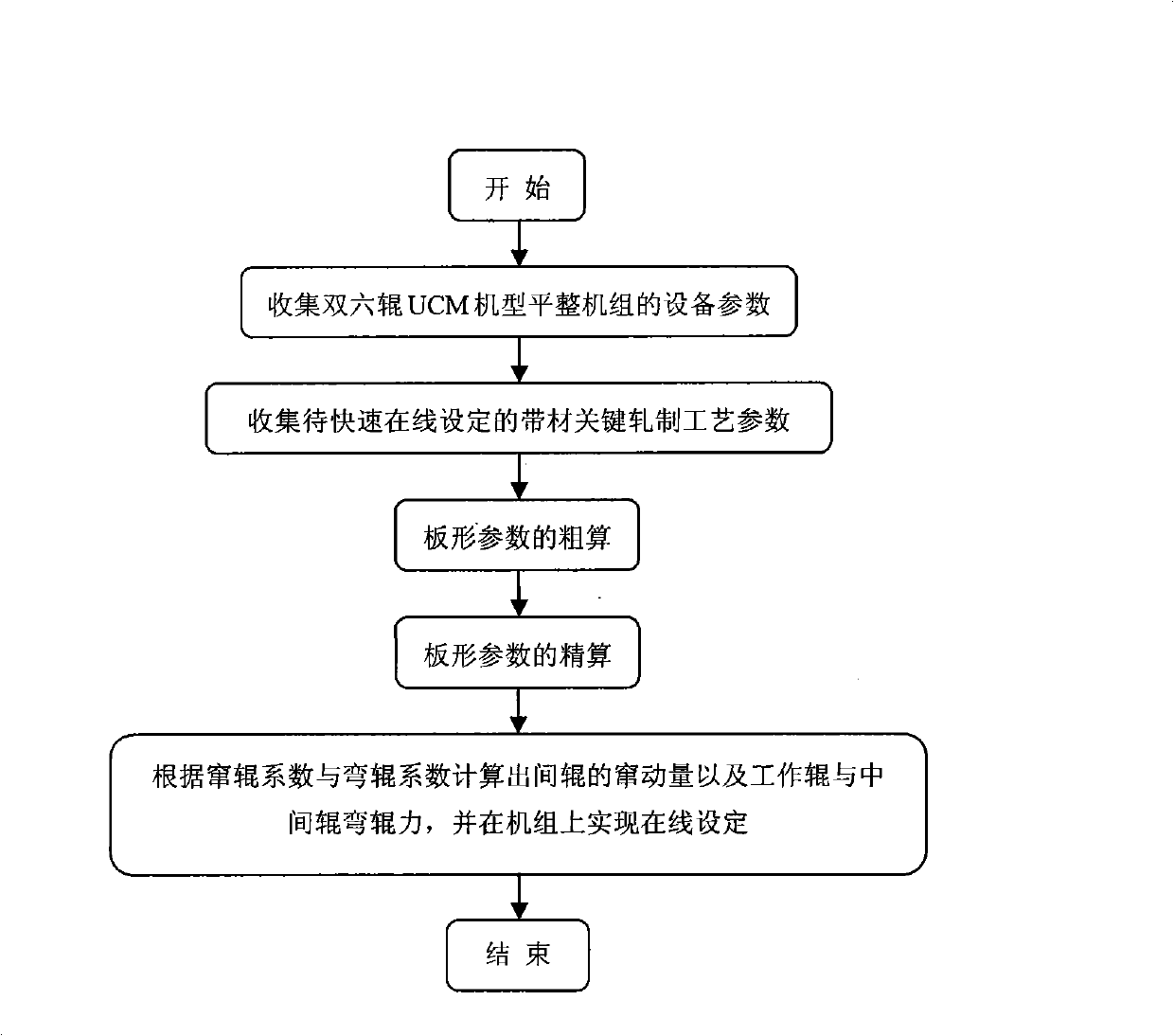

[0095] Fig. 6 is a general flow chart of on-line setting of plate shape parameters based on the mechanism model of the double UCM skin pass unit according to the present invention. Now take the strip steel with material grade SPCC, specification 0.30mm×850mm, and deformation resistance 350MPa as an example, with the help of Figure 6 to describe the process of strip steel with a specific steel type and specification on a specific double six-roller UCM type skin pass unit. The setting process and setting results of shape parameters and related effects based on the mechanism model.

[0096] First, in step 1, collect the equipment parameters of a specific double-six-roller UCM type skin pass unit, mainly including: 1# and 2# frame working roll diameter D w1 =425mm, D w2 =450mm; 1# and 2# frame intermediate roller diameter D m1 =460mm, D m2 =473mm; 1# and 2# frame support roller diameter D b1 =1096mm, D b2 =1150mm; 1# rack work rolls, intermediate rolls and support rolls are a...

Embodiment 2

[0159] In order to further illustrate the basic idea of the present invention, now the steel strip whose material grade is EDDQ, the specification is 0.21mm×740mm, and the deformation resistance is 310Mpa is taken as an example. The comprehensive process and setting results of the flatness means on the double six-roller UCM type skin pass unit and related effects.

[0160]First, in step 1, collect the equipment parameters of a specific double-six-roller UCM type skin pass unit, mainly including: 1# and 2# frame working roll diameter D w1 =525mm, D w2 =550mm; 1# and 2# frame intermediate roller diameter D m1 =520mm, D m2 =523mm; 1# and 2# frame support roller diameter D b1 =1196mm, D b2 =1250mm; 1# frame work rolls, intermediate rolls and support rolls are all flat rolls, that is, the roll shape distribution value ΔD 1wi =0, ΔD 1mi =0, ΔD 1bi = 0; 2# frame work rolls, intermediate rolls and support rolls also use flat rolls, that is, the roll shape distribution value Δ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com