Printing plate for intaglio offset and manufacturing method thereof, methods for manufacturing substrate and display apparatus

A manufacturing method and printing plate technology, which can be applied in the directions of printed circuit manufacturing, printing device, offset printing, etc., can solve the problems of the plane shape of the ink film 121 without good reproducibility and transfer, and it is difficult to apply and manufacture TFT substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

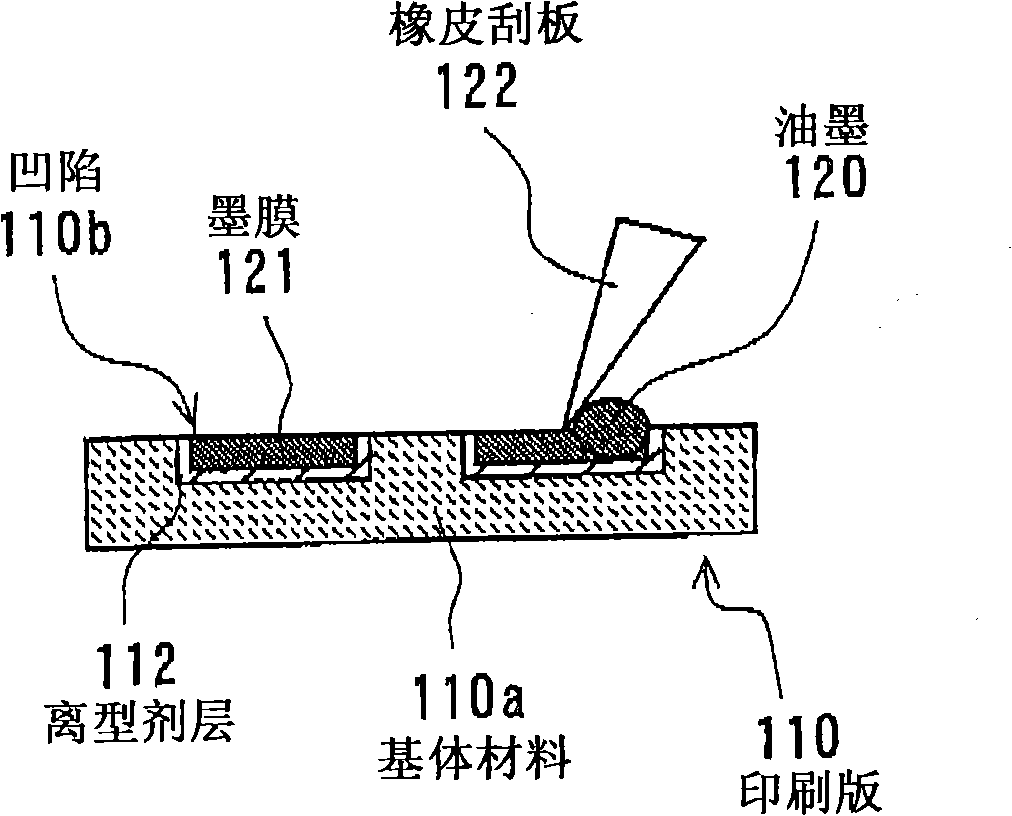

[0117] Structure of the print edition

[0118] Image 6 A schematic structural view of a printing plate 10 for reversed relief offset printing according to a first embodiment of the present invention is shown in .

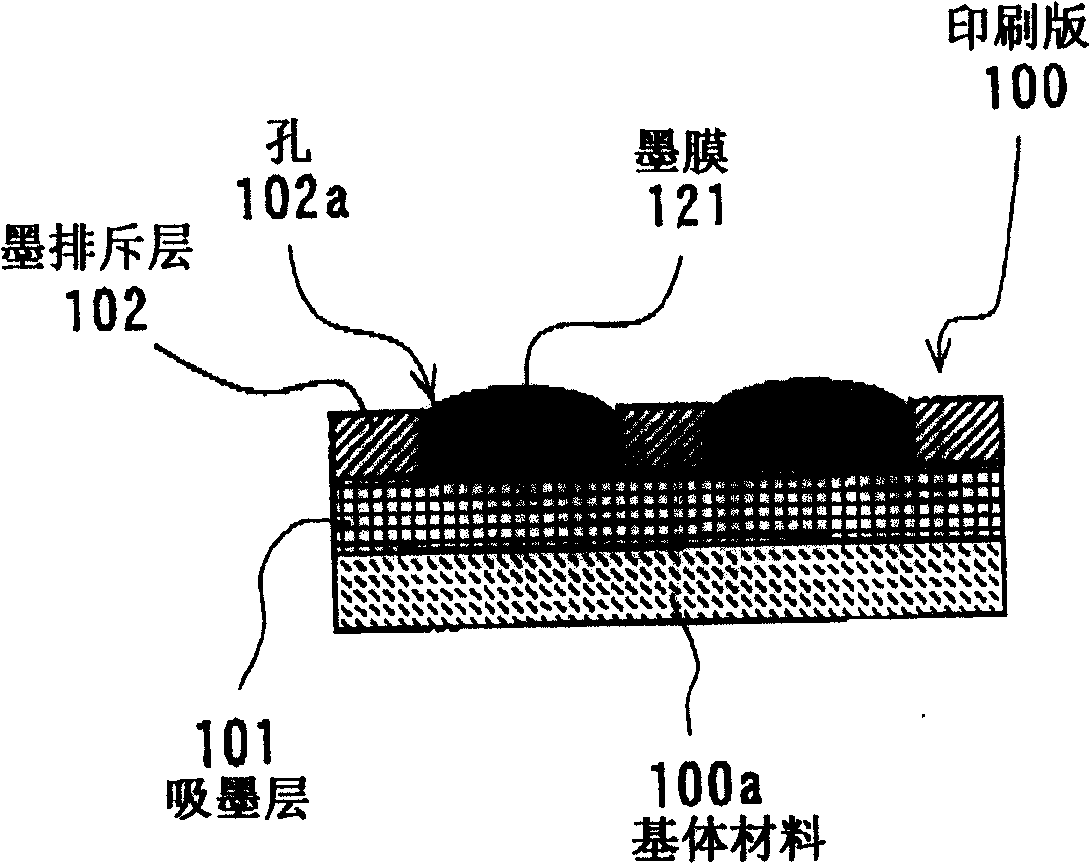

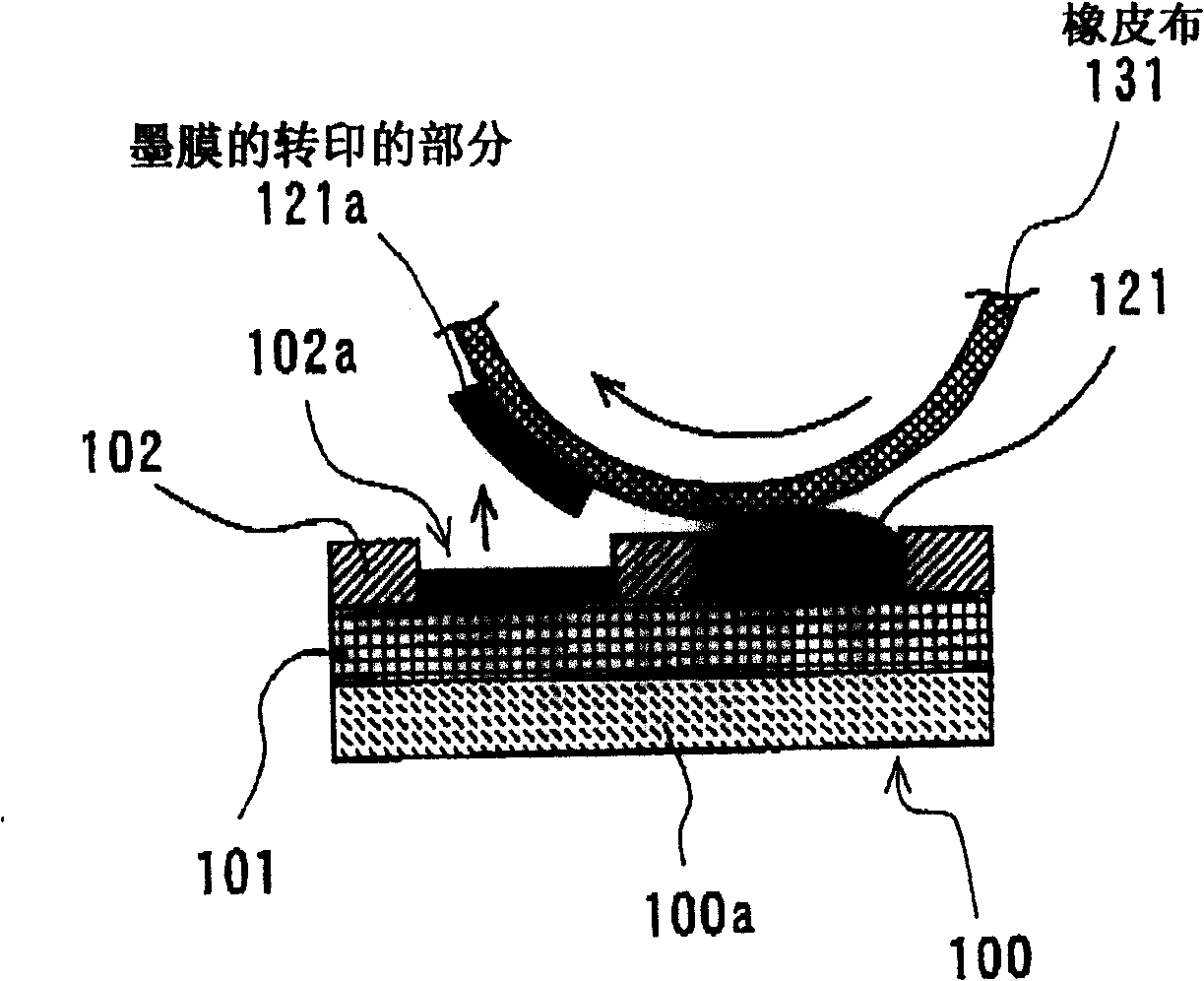

[0119] Such as Image 6 As shown in , the printing plate 10 according to the first embodiment includes a plate-shaped base material 10a having recesses 11a and 11b on its surface, and ink repellent layers 12a and 12a respectively formed on the inner surfaces of the recesses 11a and 11b. 12b. The entire inner surfaces of the recesses 11a and 11b are covered with ink repellent layers 12a and 12b, respectively. As a result, depressions 13a and 13b are formed on the surface of base material 10a. The depression 13a is defined by the concave portion 11a and the ink repelling layer 12a. The depression 13b is defined by the concave portion 11b and the ink repelling layer 12b. The portion of the plate 10 other than the recesses 13 a and 13 b is the non-recessed portio...

no. 2 example

[0193] Figure 13B is a schematic partial cross-sectional view of a printing plate 10A according to a second embodiment of the present invention.

[0194] The printing plate 10A according to the second embodiment is covered with a pattern-formed Cr film 41A except that the surface of the plate-shaped base material 10a (that is, the surface other than the concave portion 14) in the region other than the concave portions 11a and 11b is covered with a patterned Cr film 41A. Structurally the same as the printing plate 10 according to the first embodiment. Therefore, by giving Figures 12A to 12C and Figures 13A to 13BThe same or corresponding parts in 10 are attached with the same reference numerals used in the first embodiment, and the explanation of the same structure is omitted.

[0195] With the printing plate 10A of the second embodiment, the surface of the non-recessed portion 14 of the base material 10a is covered with the patterned Cr film 41A, so the ink-absorbing surfa...

no. 3 example

[0212] Figure 16 is a partial cross-sectional view of a printing plate 10B according to a third embodiment of the present invention.

[0213] Except that the flat surface 10aa of the plate-like base material 10a (that is, the flat surface of the non-recessed portion 14) in the region other than the concave portions 11a and 11b is roughened by minute protrusions and dimples, according to the second embodiment The printing plate 10B is identical in structure to the printing plate 10 according to the first embodiment. Therefore, by giving Figures 14A to 14C , Figures 15A to 15C with Figure 16 The same or corresponding parts in 10 are attached with the same reference numerals used in the first embodiment, and the explanation of the same structure is omitted.

[0214] With the printing plate 10A of the third embodiment, since the surface 10aa of the non-recessed portion 14 becomes rough, the ink affinity of the non-recessed portion 14 is higher than that of the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com