Rubber direct carving platemaking technology suitable for figured cloth printing

A rubber and technical technology, applied in the field of rubber direct engraving plate making, can solve the problems of low efficiency and high comprehensive manufacturing cost, and achieve the effect of long service life, improved surface energy of printing plates, and less interference with stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

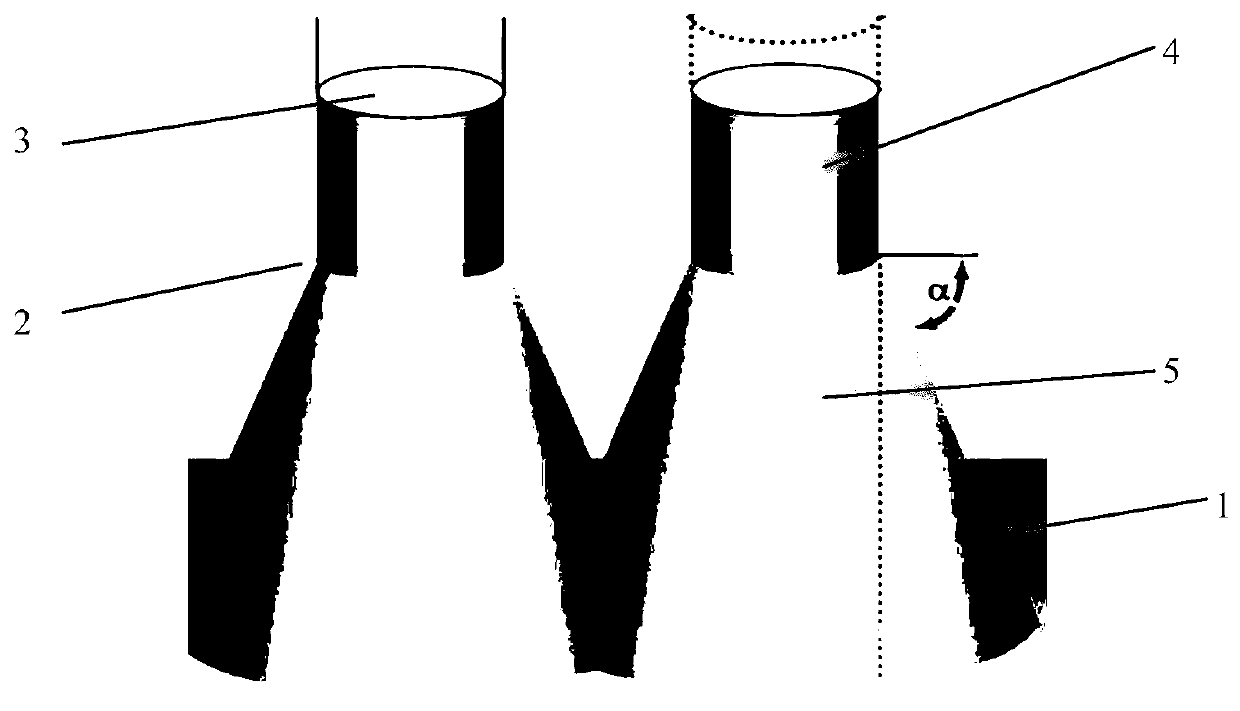

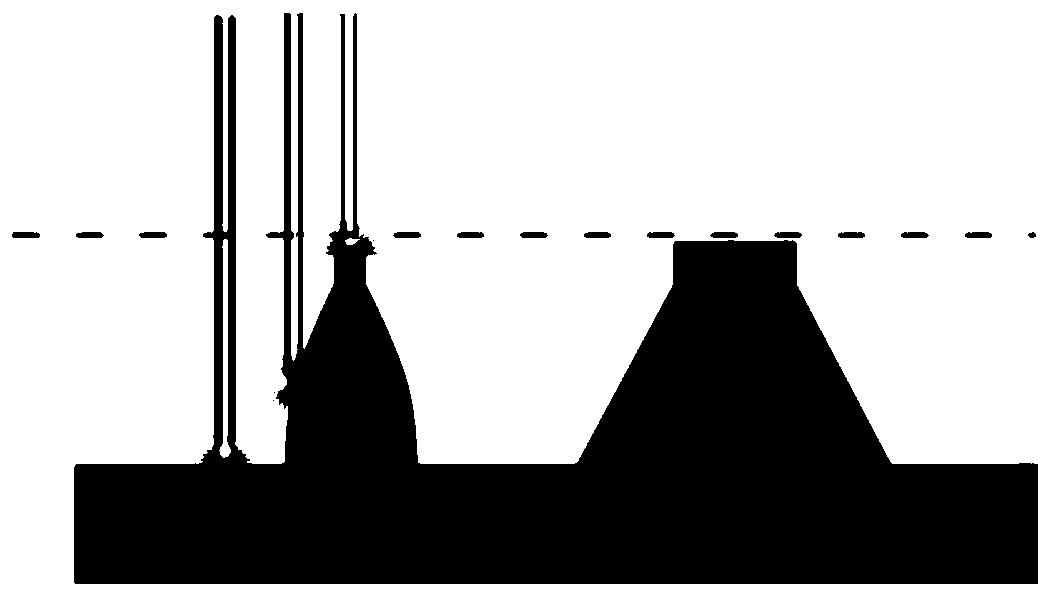

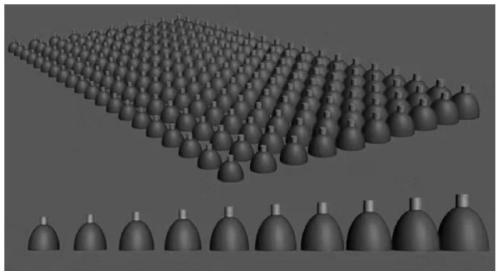

[0049] Embodiment 1 of the present invention provides a rubber direct engraving plate-making technology suitable for calico printing, including a base 1 and a relief 2, the relief 2 is located above the foundation 1 to form a printing plate; the top of the relief 2 has a printing plate The printing plate dot 3 on which the printing dot is formed.

[0050] The height of the base 1 is 450um; the height of the relief 2 is 640um.

[0051] The upper part of the relief is a cylinder 4 with a height of 225um.

[0052] The lower part of the relief is a cone 5, and the included angle between the slope of the cone and the bottom plane is 52°.

[0053] The top cross-sectional shape of the cone 5 is the same as the bottom cross-sectional shape of the cylinder 4 .

[0054] The screen ruling of the printing plate is 62L / Inch.

[0055] In monochrome plate printing, the screening angle of the printing plate is kept at 30° to the 45° latitude and longitude of the fiber cloth.

[0056] The do...

Embodiment 2

[0060] Embodiment 2 of the present invention provides a rubber direct engraving plate-making technology suitable for calico printing, including a base 1 and a relief 2, and the relief 2 is located above the foundation 1 to form a printing plate; the top of the relief 2 has a printing plate The printing plate dot 3 on which the printing dot is formed.

[0061] The height of the base 1 is 450um; the height of the relief 2 is 640um.

[0062] The upper part of the relief is a cylinder 4 with a height of 225um.

[0063] The lower part of the relief is a cone 5, and the included angle between the slope of the cone and the bottom plane is 52°.

[0064] The top cross-sectional shape of the cone 5 is the same as the bottom cross-sectional shape of the cylinder 4 .

[0065] The screen ruling of the printing plate is 62L / Inch.

[0066] In two-color overprinting, the screening angle of the printing plate is maintained at 15° / 75° to the 45° warp and weft of the fiber cloth.

[0067] Th...

Embodiment 3

[0071] Embodiment 3 of the present invention provides a rubber direct engraving plate-making technology suitable for calico printing, including a base 1 and a relief 2, the relief 2 is located above the foundation 1 to form a printing plate; the top of the relief 2 has The printing plate dot 3 on which the printing dot is formed.

[0072] The height of the base 1 is 450um; the height of the relief 2 is 640um.

[0073] The upper part of the relief is a cylinder 4 with a height of 225um.

[0074] The lower part of the relief is a cone 5, and the included angle between the slope of the cone and the bottom plane is 52°.

[0075] The top cross-sectional shape of the cone 5 is the same as the bottom cross-sectional shape of the cylinder 4 .

[0076] The screen ruling of the printing plate is 62L / Inch.

[0077] In three-color overprinting, the screening angle of the printing plate is kept at 0° / 22.5° / 67.5° with respect to the 45° latitude and longitude of the fiber cloth.

[0078...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com