Down draft type oil smoke discharging integrated range machine

An oil fume exhaust and downdraft technology, which is used in the removal of oil fume, household stoves, heating methods, etc., can solve problems such as complex structure, and achieve the effect of reducing structure, preventing backfire and burning, and improving negative pressure level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

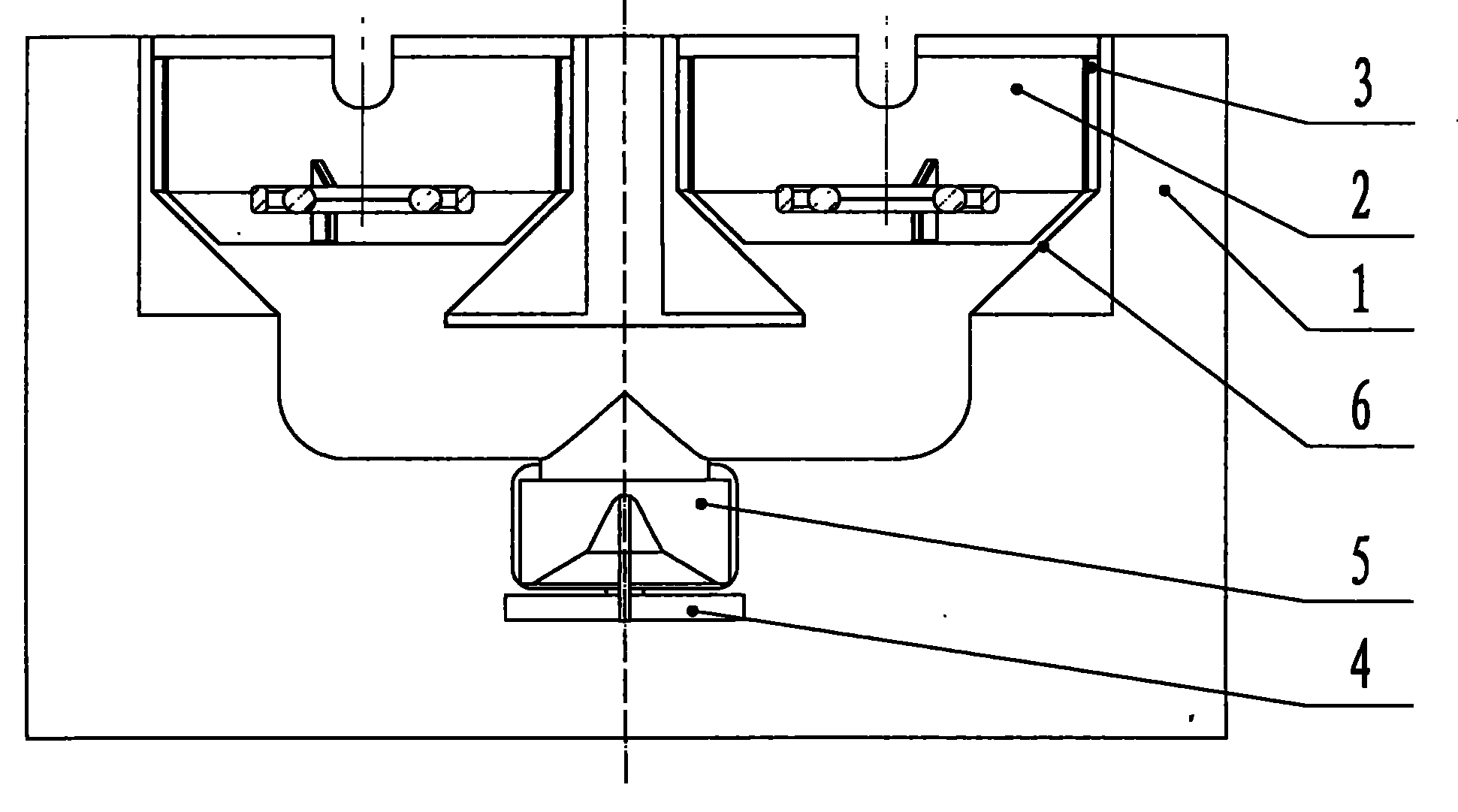

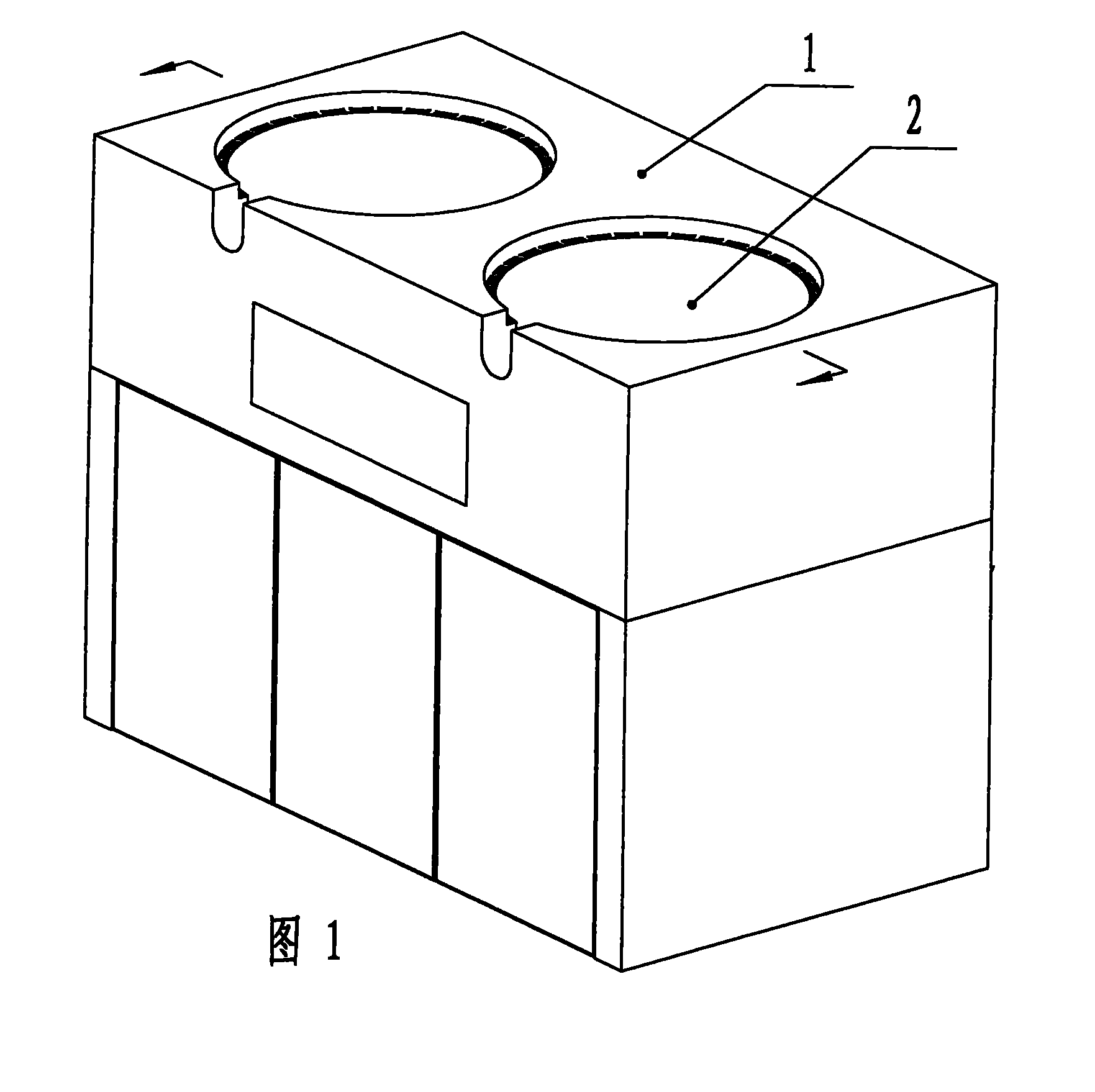

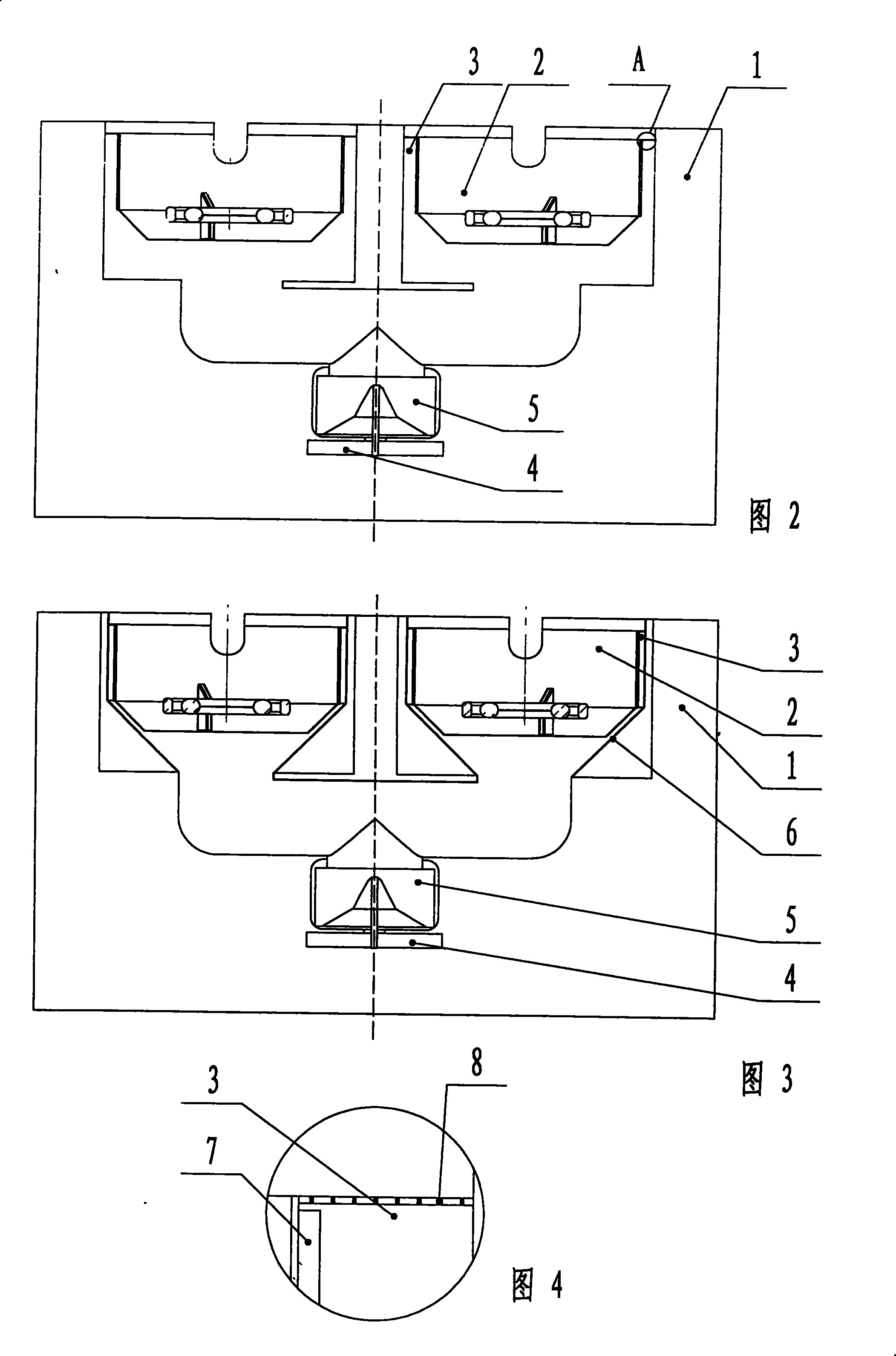

[0014] The down-suction integrated oil fume exhaust stove machine includes a casing 1 and a stove chamber 2 arranged in the casing, and an air inlet 3 is arranged around the upper part of the stove chamber, and the air inlet 3 is connected with the oil fume extraction and separation device arranged in the casing , the orientation of the air inlet 3 is vertically upward. Cooking utensils, such as gas cookers and electromagnetic cookers, are arranged in the cooker cavity during specific implementation. The described oil fume extraction and separation device is a known product, which is composed of a motor 4 and an oil fume separator 5 fixed on the motor shaft; the air inlet end of the oil fume separator 5 communicates with the air inlet 3; how does the oil fume extraction and separation device communicate with Air inlet communication is well known to those skilled in the art. The following structure is used to construct the air inlet 3 (as shown in Figure 2), that is, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com