Arrangement combination of U type pipe in solar water heater heat collection gate as well as overlapped design thereof

A solar water heater, arrangement and combination technology, applied in the directions of solar thermal collectors, solar thermal energy, solar thermal collectors using working fluid, etc. Heat gain rate, smooth convection, and the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

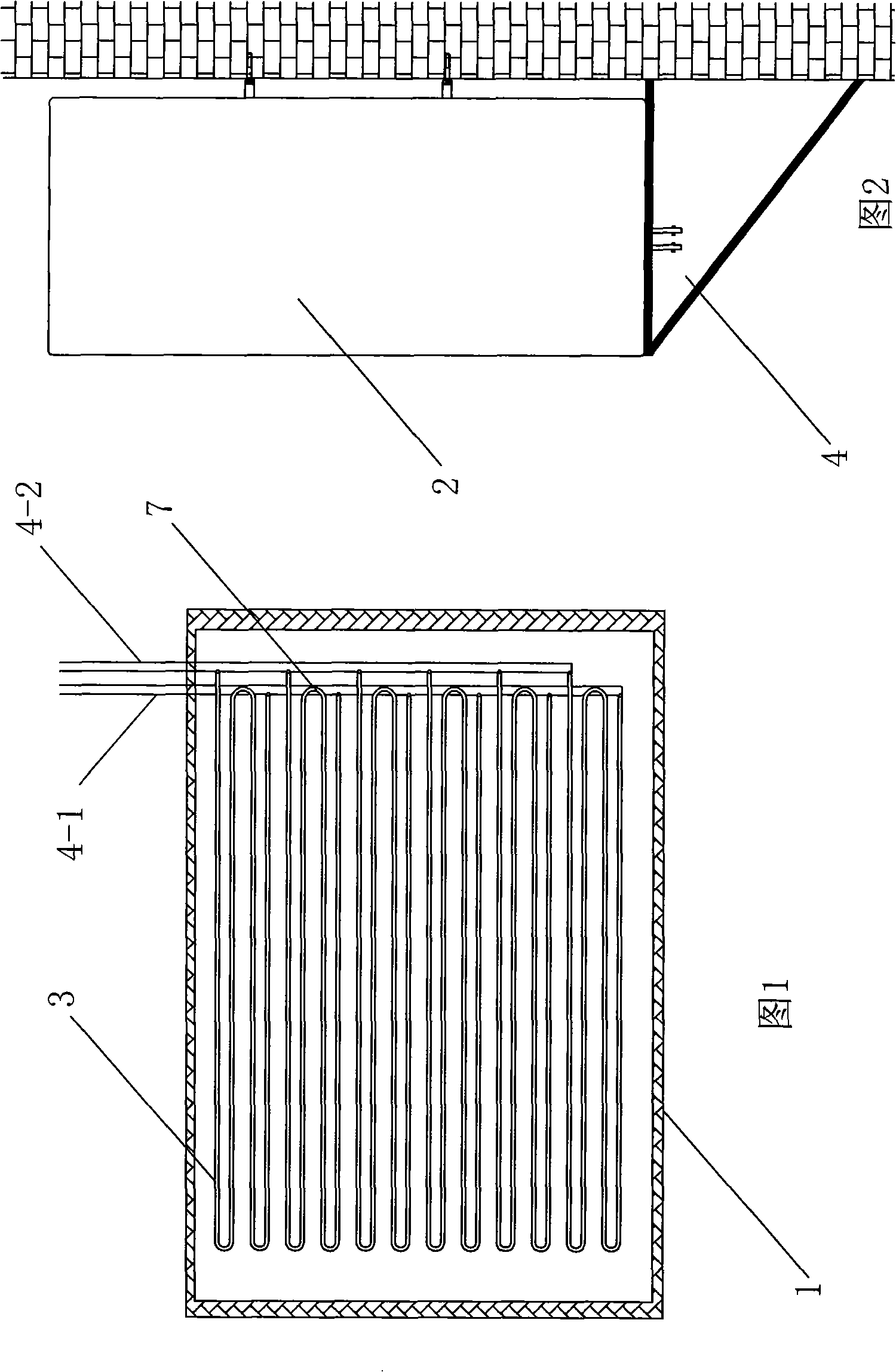

[0020] Embodiment 1: As shown in Figures 1 and 2, the solar water heater of the present invention is a split structure. The heat collecting grid 1 is placed horizontally on the outer wall of the balcony fence, and the water storage tube 2 is installed on the wall in the balcony. The tube 4 communicates with the U-shaped tube 3 in the heat collecting grid, and two exchange tubes are arranged side by side, including a cold exchange tube 4-1 and a heat exchange tube 4-2.

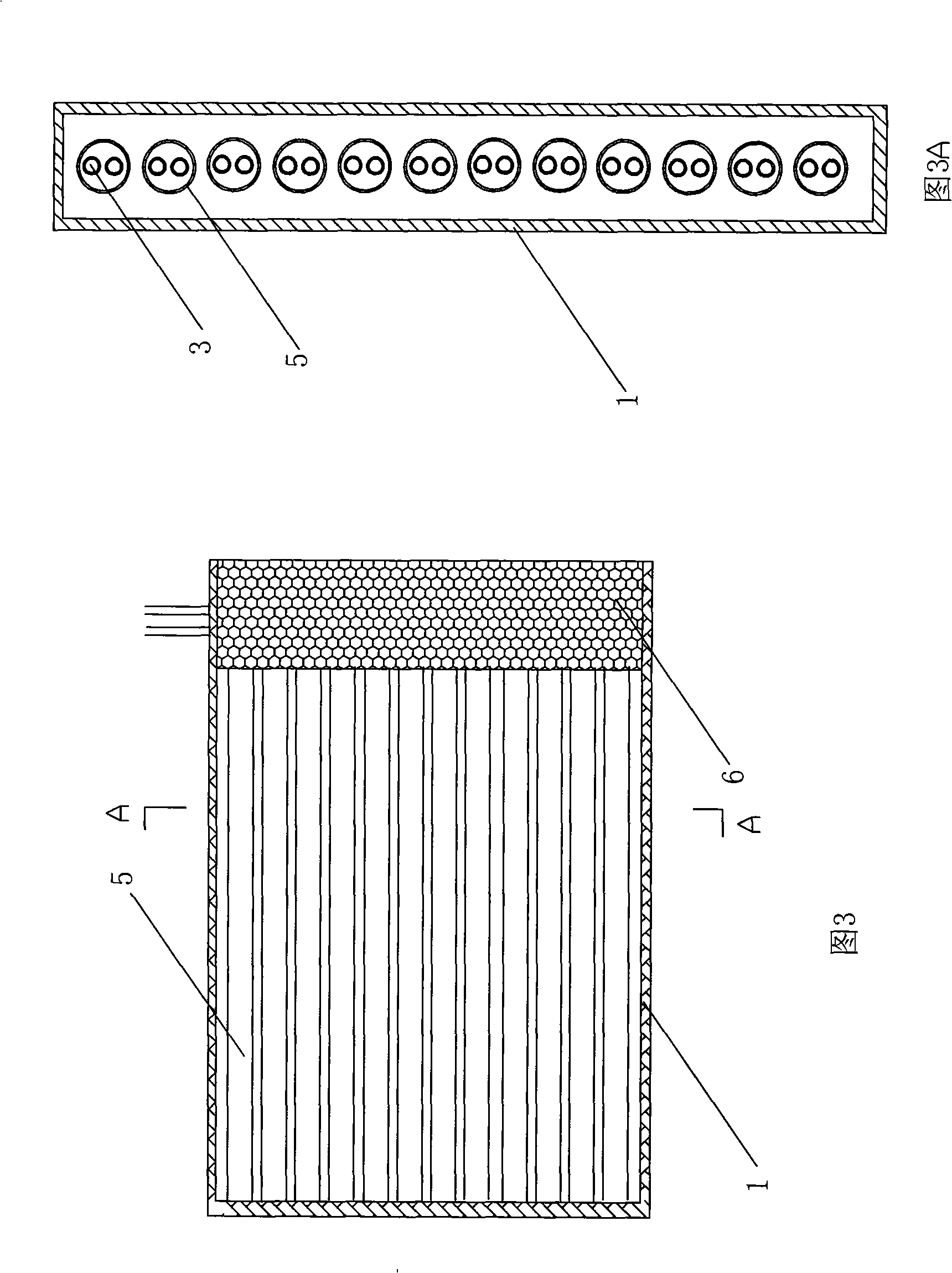

[0021] As shown in Figures 1, 3, and 3A, 12 vacuum tubes 5 with one end open are arranged up and down and installed horizontally in the heat collector grid 1, and 12 U-shaped tubes are correspondingly placed horizontally in the 12 vacuum tubes, and each 2 U-shaped tubes are placed between the vacuum tubes. The open ends are connected in series through the elbow 7 to form a heat collecting tube group with one water inlet pipe and one water outlet pipe. 6 water inlet pipes of 6 heat collecting pipe groups are con...

Embodiment 2

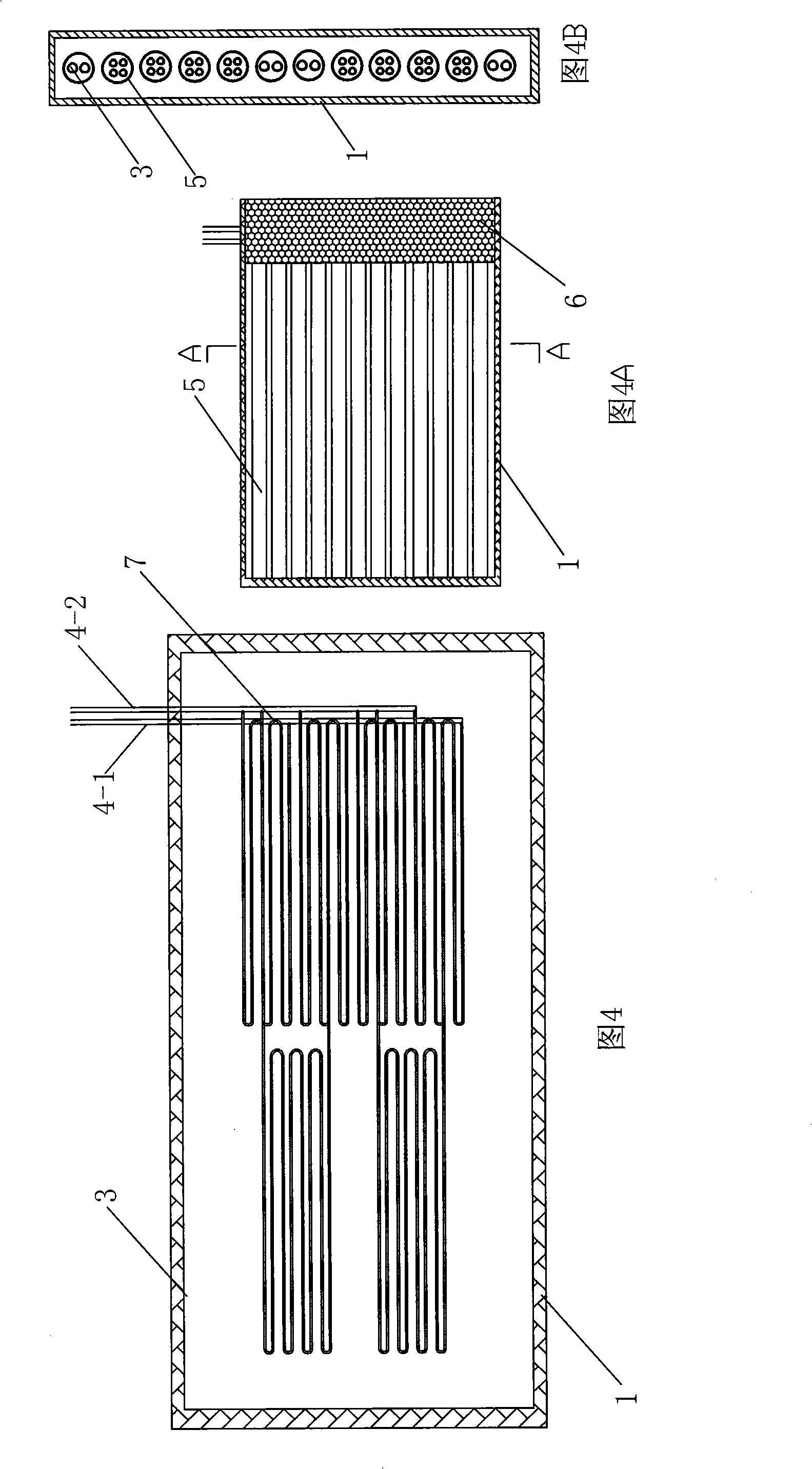

[0025] Embodiment 2: As shown in Figures 4, 4A, and 4B, 12 vacuum tubes 5 with one end open are arranged up and down and installed horizontally in the heat collecting grid 1, and 12 U-shaped tubes are correspondingly placed horizontally in 12 vacuum tubes, and each 3 U-shaped tubes The tubes are connected in series through the elbow 7 at the open end of the vacuum tube to form a heat collecting tube group with a water inlet pipe and a water outlet pipe. The water inlet pipe is located below the heat collecting tube group, and the water outlet pipe is located above the heat collecting tube group. 4 heat collecting tube groups, 4 water inlet pipes of the 4 heat collecting tube groups are connected in parallel on the cold exchange pipe 4-1, and 4 water outlet pipes are connected in parallel on the heat exchange pipe 4-2. Then divide the 8 U-shaped tubes into 2 heat-collecting tube groups, and each 4 U-shaped tubes are connected in series through an elbow to form a heat-collecting ...

Embodiment 3

[0026]Embodiment 3: As shown in Figures 5, 5A, and 5B, 12 vacuum tubes 5 with one end open are arranged up and down and installed horizontally in the heat collecting grid 1, and 12 U-shaped tubes are correspondingly placed horizontally in 12 vacuum tubes, and each 4 U-shaped tubes The tubes are connected in series through the elbow 7 at the open end of the vacuum tube to form a heat collecting tube group with a water inlet pipe and a water outlet pipe. The water inlet pipe is located below the heat collecting tube group, and the water outlet pipe is located above the heat collecting tube group. 3 heat collecting tube groups, 3 water inlet pipes of the 3 heat collecting tube groups are connected in parallel on the cold exchange pipe 4-1, and 3 water outlet pipes are connected in parallel on the heat exchange pipe 4-2. Then divide the 6 U-shaped tubes into 3 heat-collecting tube groups, each 2 U-shaped tubes are connected in series through an elbow to form a heat-collecting tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com