Oil mist characteristic testing equipment

A characteristic testing, oil mist technology, applied in material inspection products, injection devices, liquid injection devices, etc., can solve problems such as the inability to effectively simulate the method of metal processing into mist, and the inability to accurately evaluate the oil mist characteristics of processing fluids, and achieve good technology. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

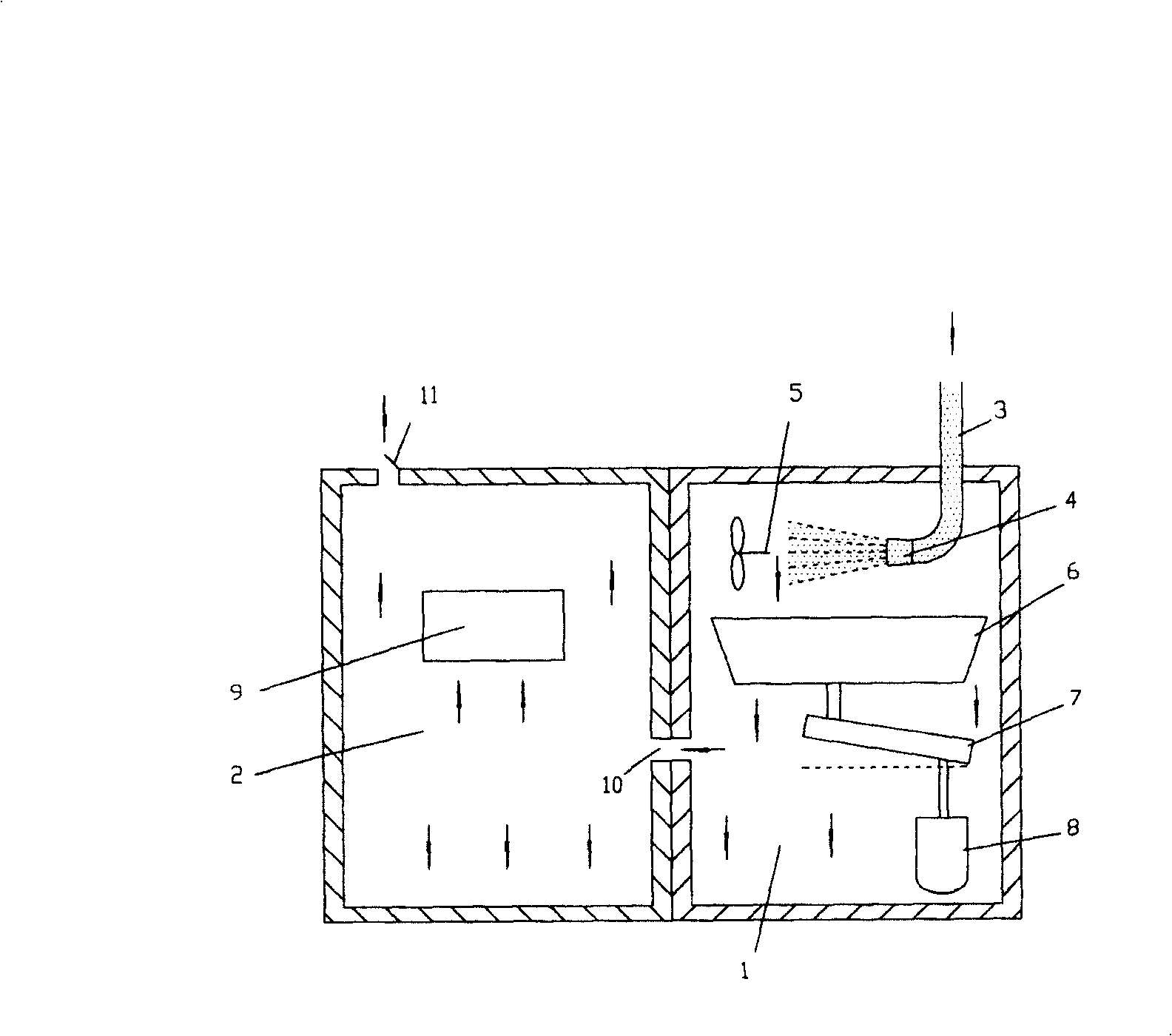

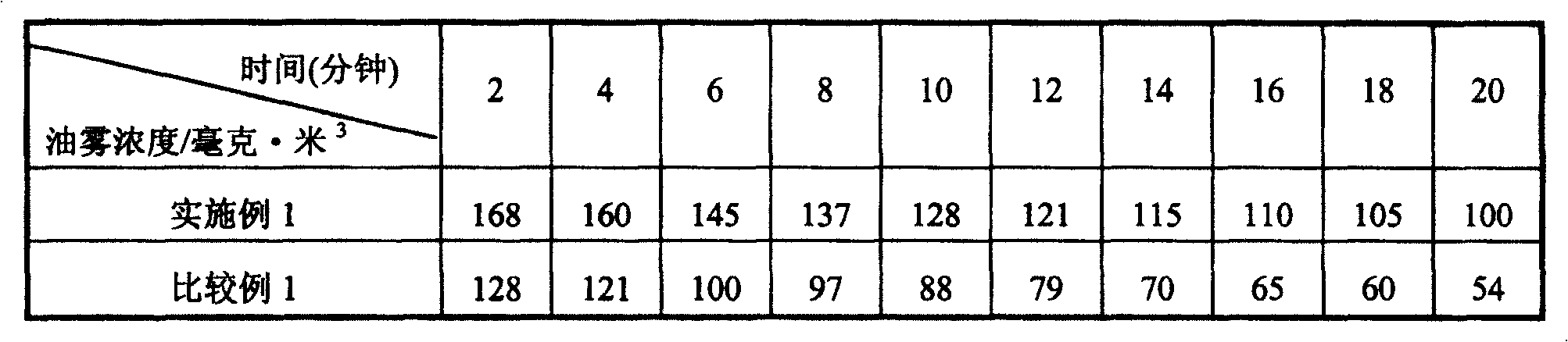

[0029] according to figure 1The oil mist characteristic testing equipment in the center is used to test the oil mist characteristics of oil products under the coexistence of three fogging methods. The size of the spray chamber and the oil mist test chamber are the same, both are 40×40×50 cm. The included angle is 10°, the temperature in the spray chamber and the oil mist test chamber is 25°C, the pressure is 1MPa, the temperature of the heating plate is 150°C, and the oil sample used is N15 base oil with 0.5% oil mist suppression For the oil product after agent A, the injection volume of the spray port is 10 ml, and the characteristic values of the oil mist are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com